Low pressure molding package structure for fuel cell

A low-pressure molding, fuel cell technology, applied to fuel cell type half cells and primary cell type half cells, structural parts, battery pack parts, etc. problems such as the structural surface of the adhesive material to achieve the effect of simplifying the production process and eliminating air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

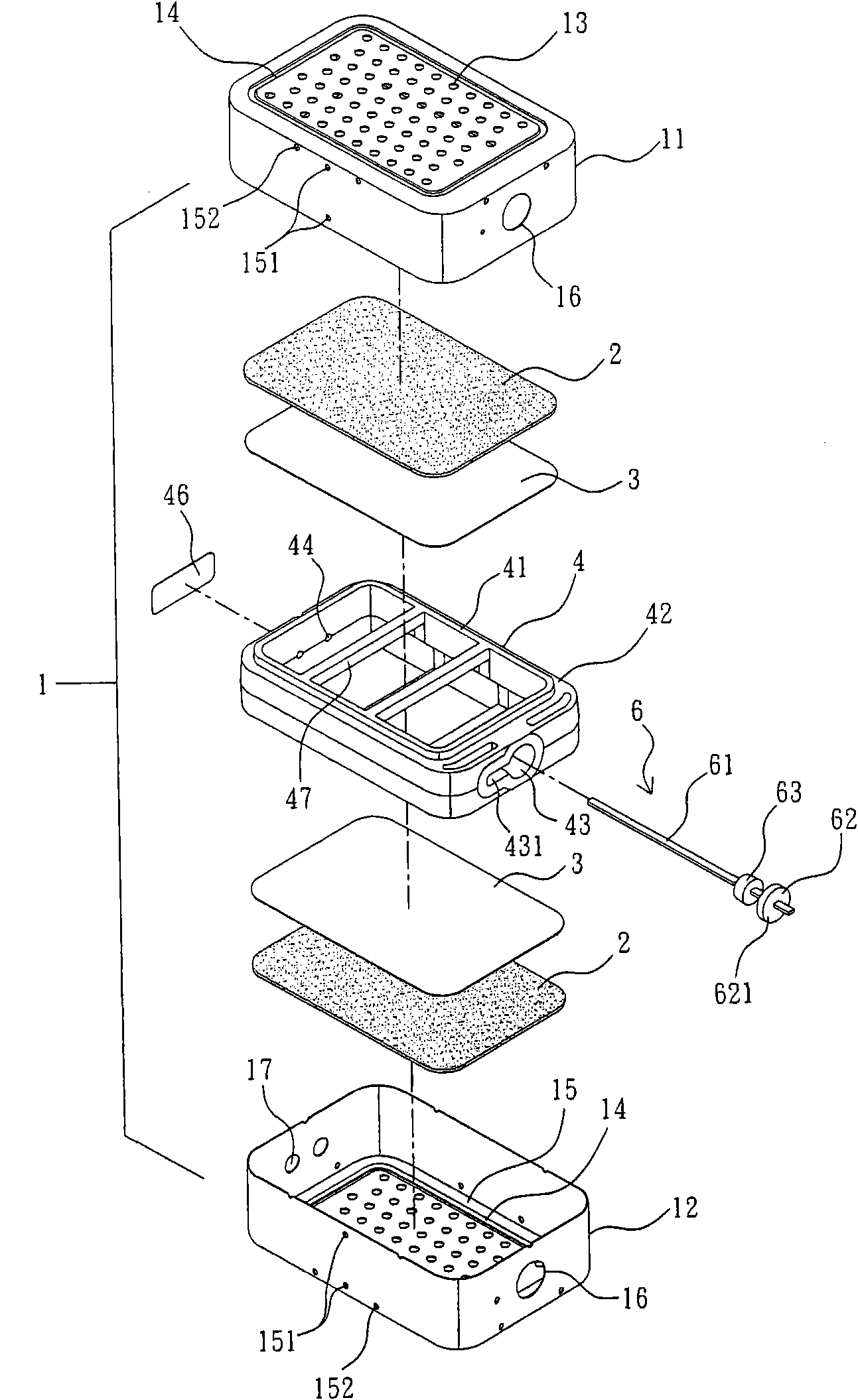

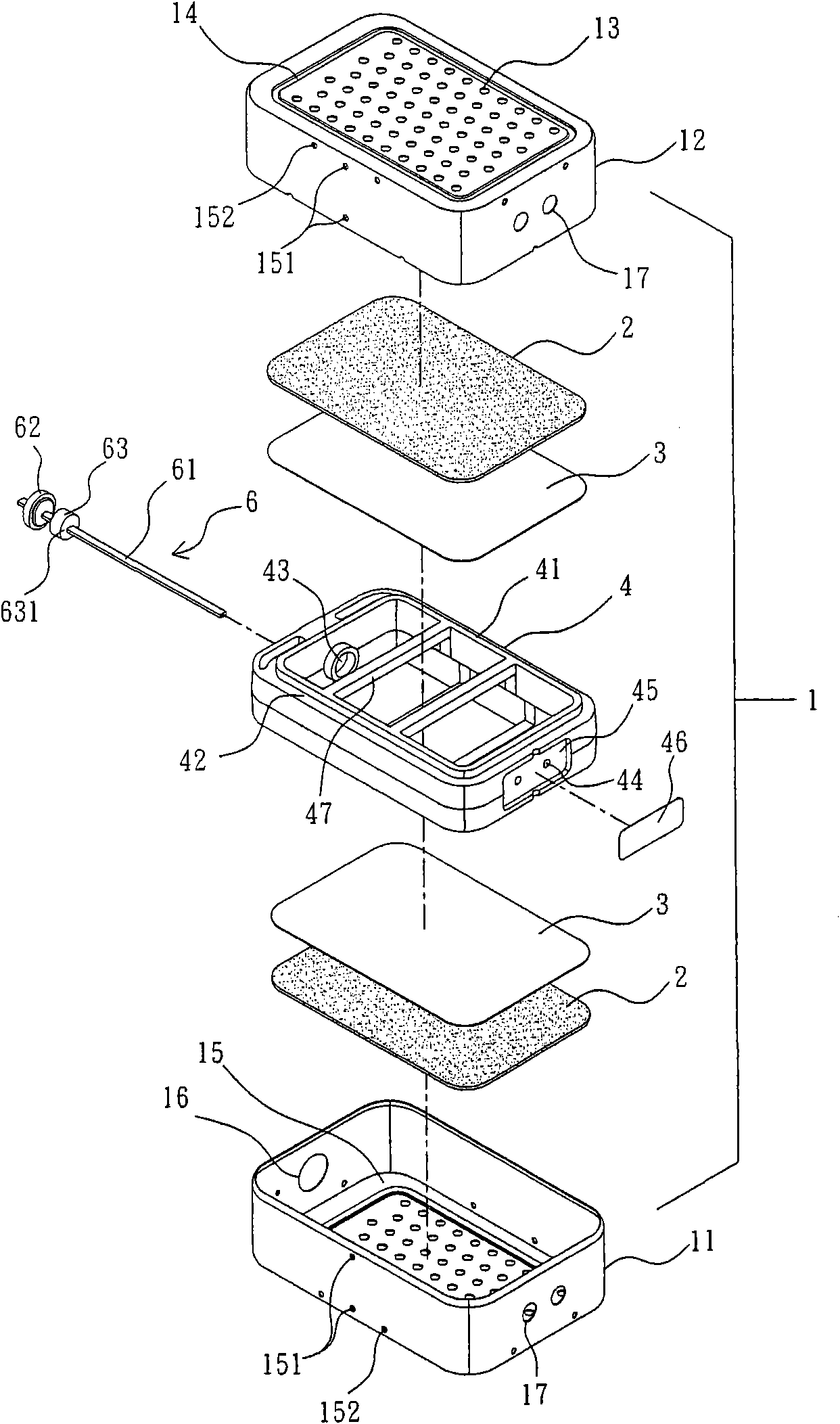

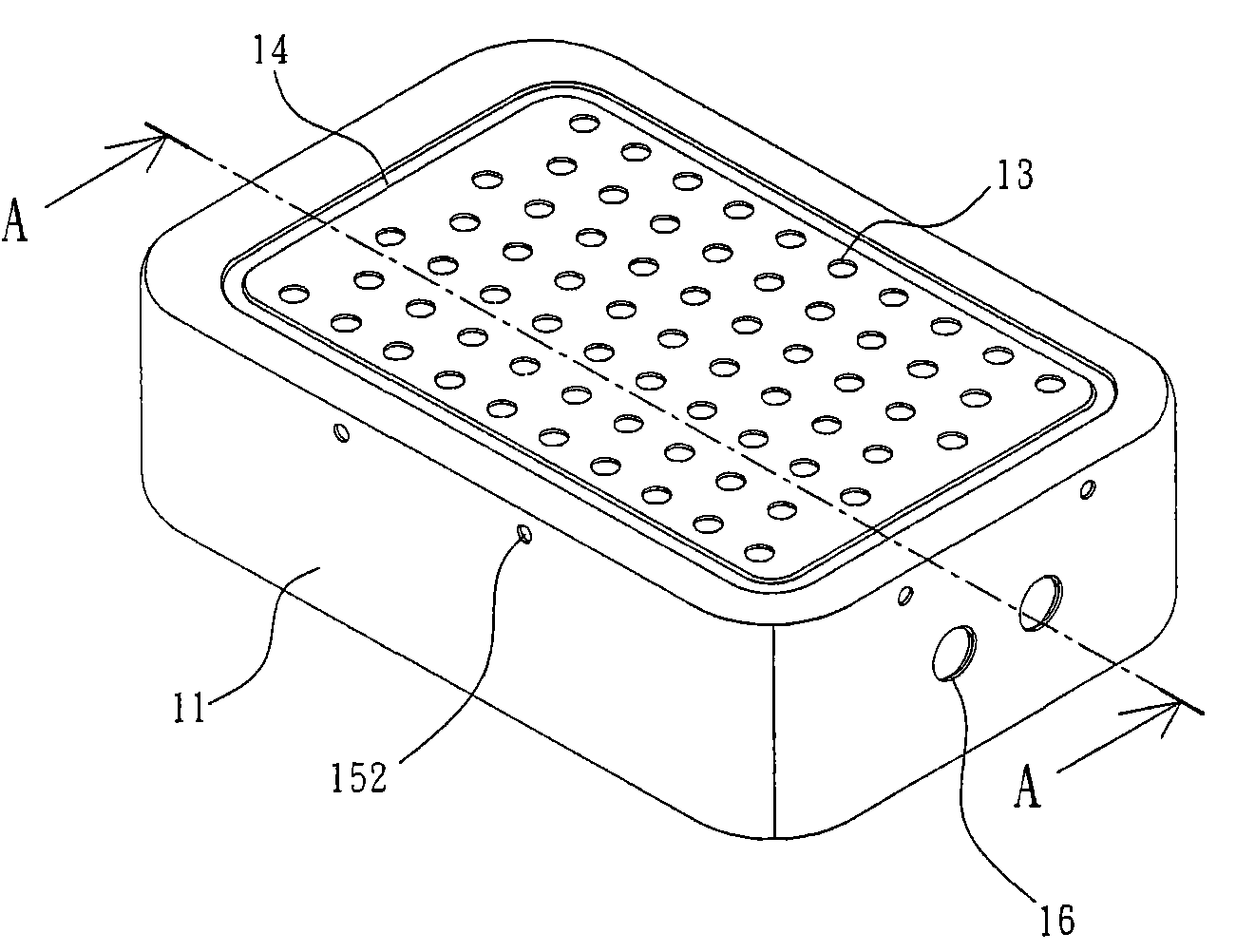

[0031] In order to further disclose the specific technical content of the present invention, first please refer to the accompanying drawings, wherein, figure 1 It is an exploded perspective view of the first embodiment of the fuel cell of the present invention; figure 2 for figure 1 An exploded perspective view of the shown fuel cell from another perspective; Figure 3a and Figure 3b It is a perspective view of different viewing angles after the first embodiment of the fuel cell of the present invention is assembled; Figure 4 for Figure 3a a sectional view taken along the line A-A; Figure 5 for Figure 3b a sectional view taken along the line B-B; Image 6 It is an exploded perspective view of the second embodiment of the fuel cell of the present invention; Figure 7 for Image 6 An exploded perspective view of the shown fuel cell from another perspective; Figure 8 It is an assembled perspective view of the second embodiment of the fuel cell of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| ductility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com