Method for forming pipe fitting with internal high pressure and external low pressure and forming machine

A low-pressure forming and internal high-pressure technology, applied in the field of pipe fittings production equipment, can solve the problems of high weld quality requirements, reduce the proportion of forming cracks, and high processing costs, and achieve the advantages of less forming process, improved stretching effect, and reduced processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

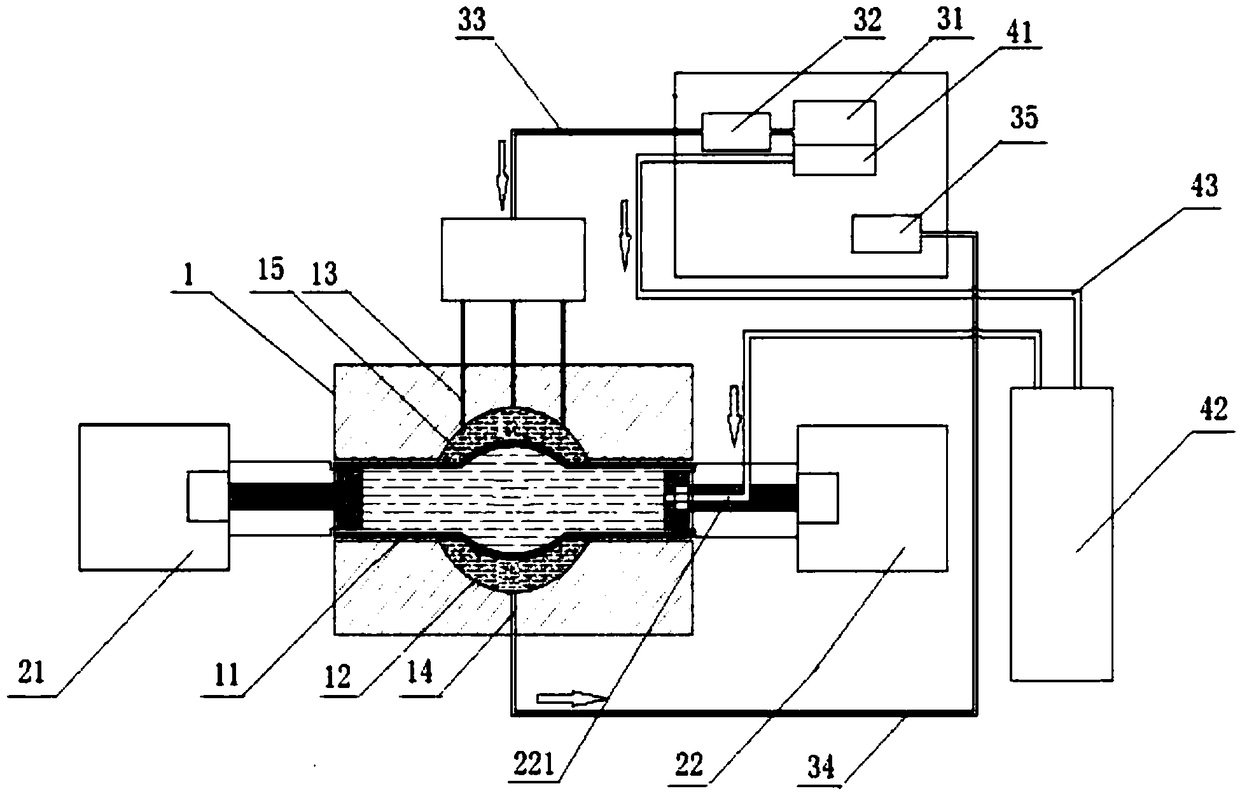

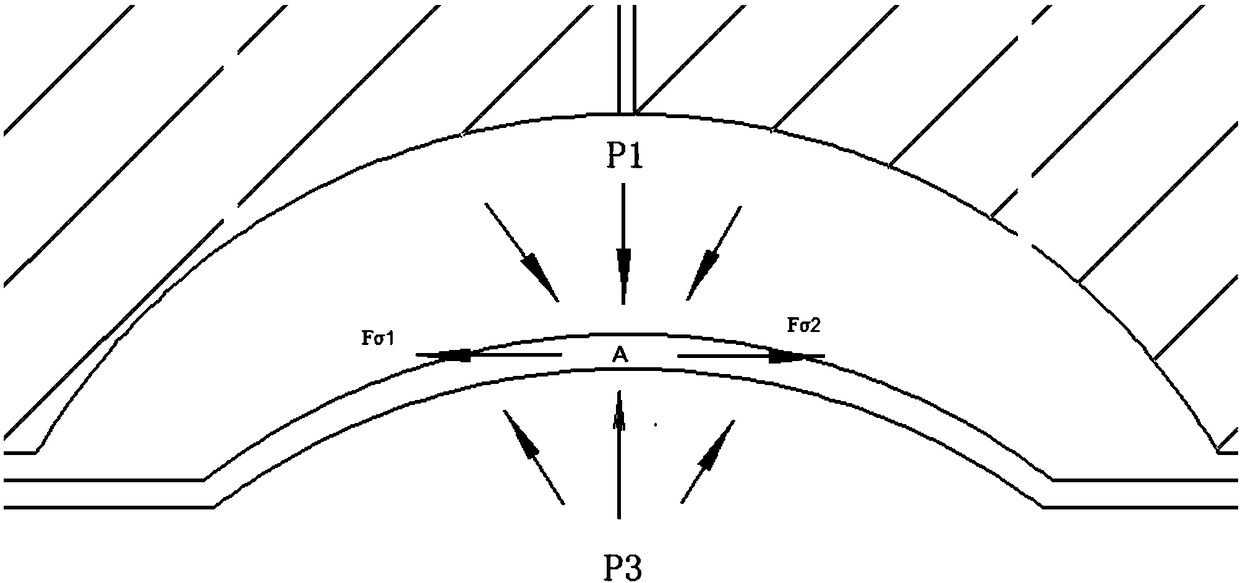

[0031] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a pipe fitting internal high pressure external low pressure forming machine proposed by the present invention, figure 2 It is a schematic diagram of a pipe fitting internal high pressure external low pressure forming method proposed by the present invention and the force analysis under the working state of the forming machine.

[0032] refer to figure 1 , a kind of pipe fitting internal high pressure external low pressure forming method proposed by the present invention comprises the following steps:

[0033] S1. Put the pipe fitting to be formed into the mold cavity, an expanding area 15 is formed between the pipe fitting to be formed and the inner wall of the cavity, and the mold is provided with a first through hole 13 and a second through hole 14, through which the first through hole 13 Continuously inject low-pressure fluid into the expansion area 15, and the low-pressure fluid is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com