Mounting tool for spring ring

The technology of a spring coil and an installer, which is applied in the field of assembly tooling, can solve the problems of deformation of the spring coil, incomplete recovery of the spring coil, low efficiency, etc., and achieves the effects of being convenient to carry and use, avoiding serious local deformation, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific examples.

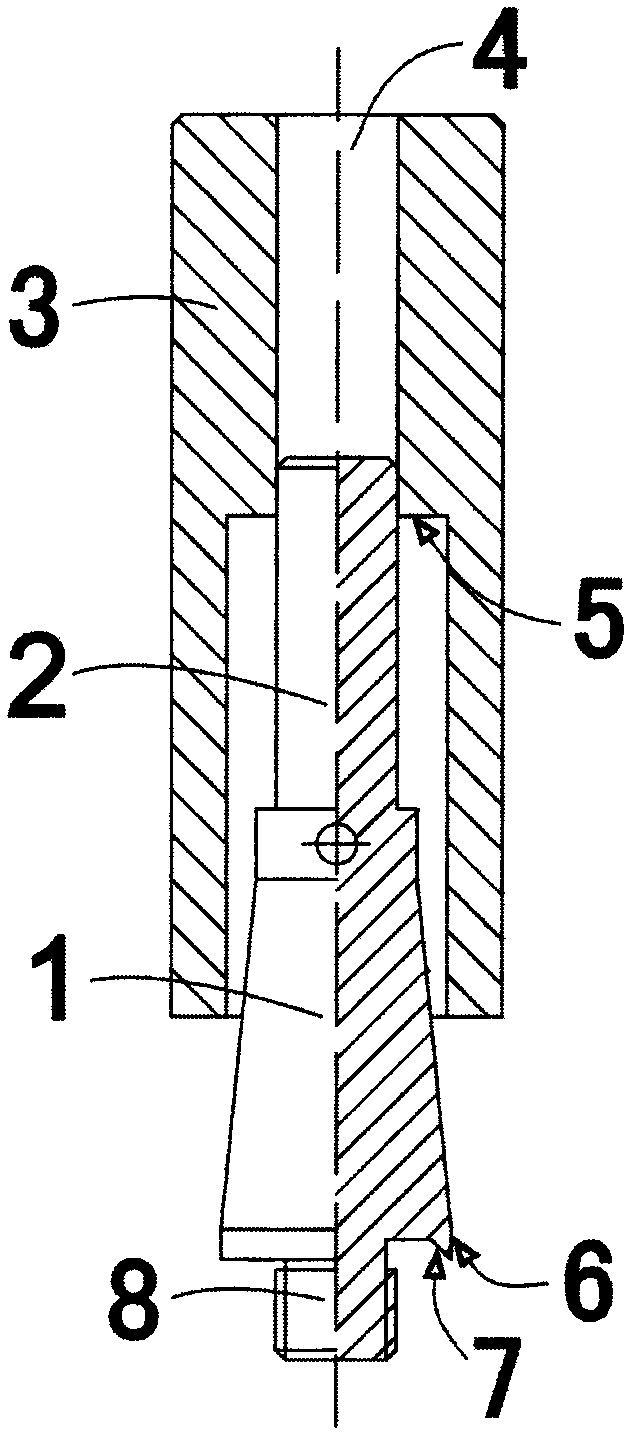

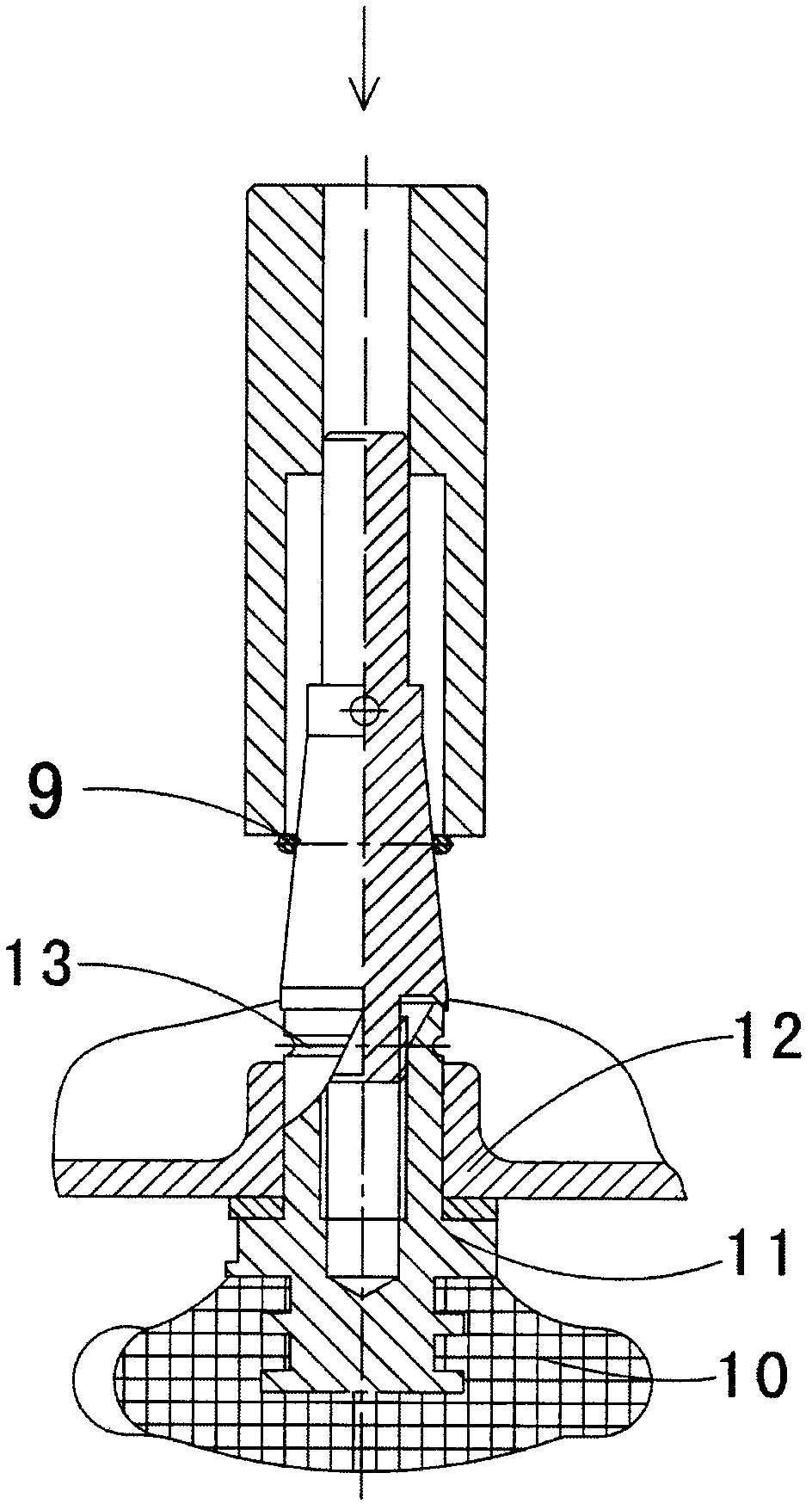

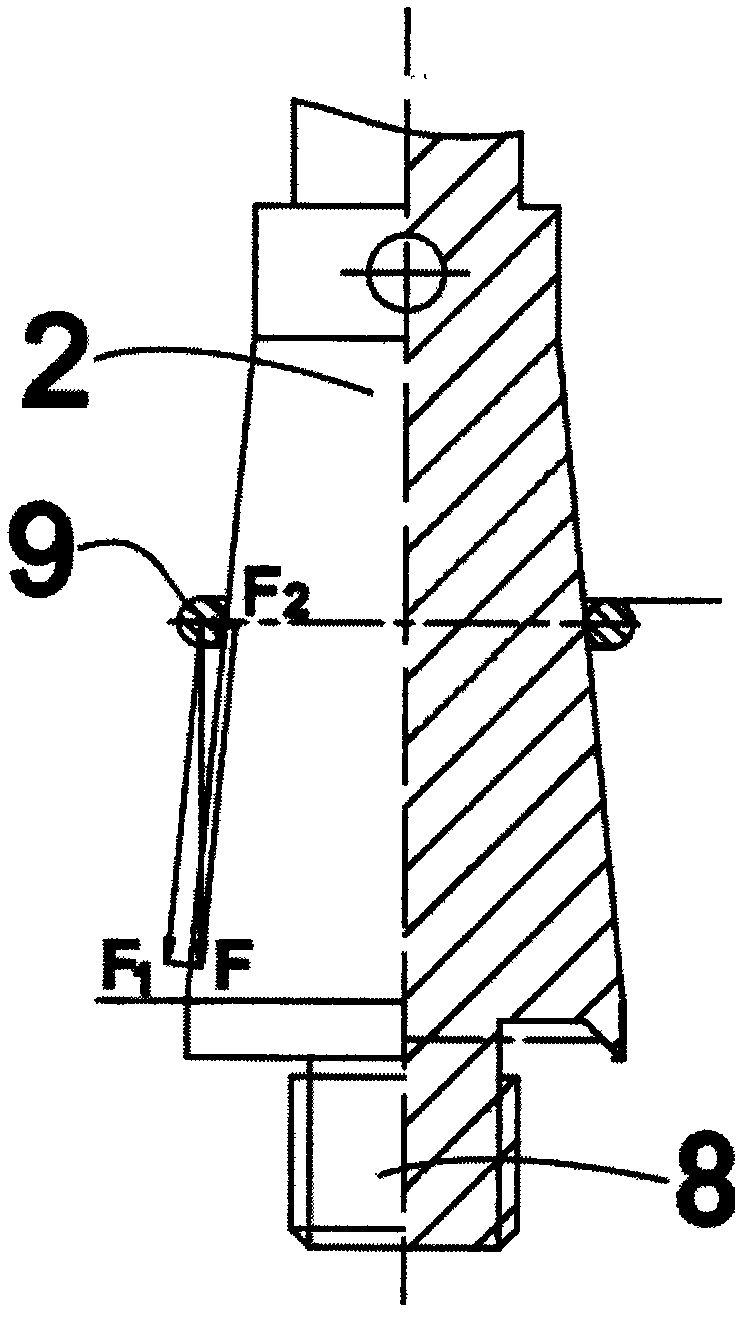

[0011] see figure 1 and figure 2 , the spring coil installer includes a frustum-shaped guide body 1 and a push cylinder 3 that is clearance fit with the guide body 1, and the inner diameter of the push cylinder 3 is slightly larger than the maximum diameter of the guide body 1 and smaller than the Install the outer diameter of spring ring 9, the minimum diameter of described guide body 1 is less than the internal diameter of installed spring ring 9, and described guide body 1 is a small taper circular platform; The maximum diameter of described guide body 1 is slightly larger than the desired installation spring ring. The shaft diameter of the shaft, and on the end surface of the largest diameter of the guide body 1, there is a connecting threaded post 8, which is coaxial with the guide body 1.

[0012] This example is further explained by installing the spring ring 9 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com