Notched pre-preg and notched pre-preg sheet

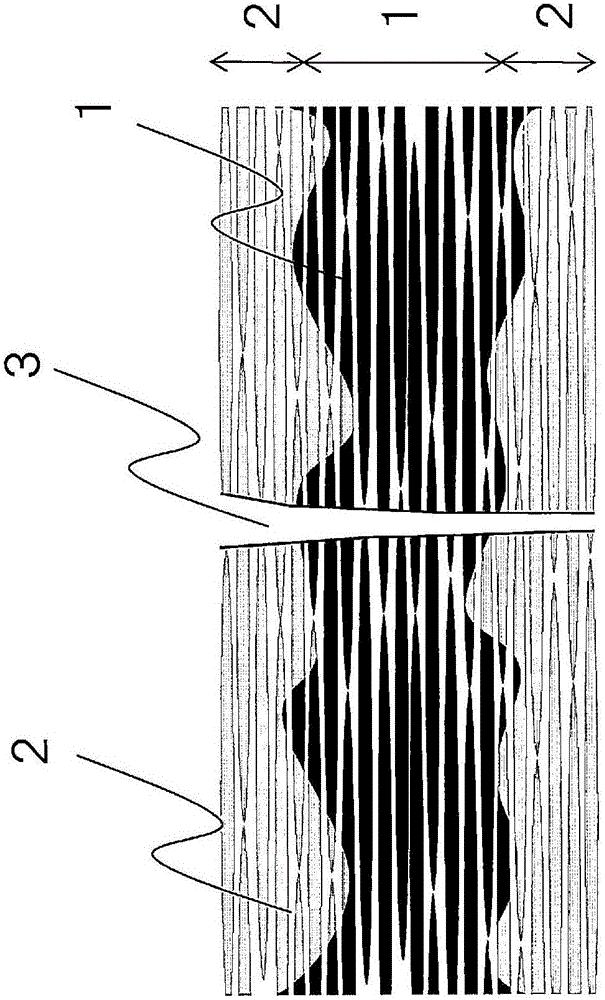

A technology of prepreg and prepreg, which is applied in the direction of synthetic resin layered products, vehicle parts, metal layered products, etc. It can solve the problems that it is difficult to apply molding pressure and prone to pores, so as to suppress wrinkles and pores Occurrence, excellent formability, and the effect of suppressing the decline in the strength of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] 13 parts by mass of PES5003P was added and dissolved in 60 parts by mass of "Alaldite (registered trademark)" Y9655 and 40 parts by mass of "Epon (registered trademark)" 825 in a kneader, and 20 parts by mass were kneaded as Then, 45 parts by weight of "Arador (registered trademark)" 9664-1 was kneaded with fine particles of thermoplastic resin particles as a curing agent to prepare a thermosetting resin composition.

[0093] In addition, the above-mentioned microparticles were produced by the following method. 90 parts by mass of transparent polyamide (product name: グリルアミド (registered trademark)-TR55, manufactured by EMSER Werke Co., Ltd.), 7.5 parts by mass of epoxy resin (product name: Epicoat (registered trademark) 828, manufactured by Shell Petrochemical Co., Ltd.) and cured 2.5 parts by mass of a solvent (product name: Tomaid (registered trademark) #296, manufactured by Fuji Chemical Industry Co., Ltd.) was added to a solvent mixture containing 300 parts by mass o...

Embodiment 2

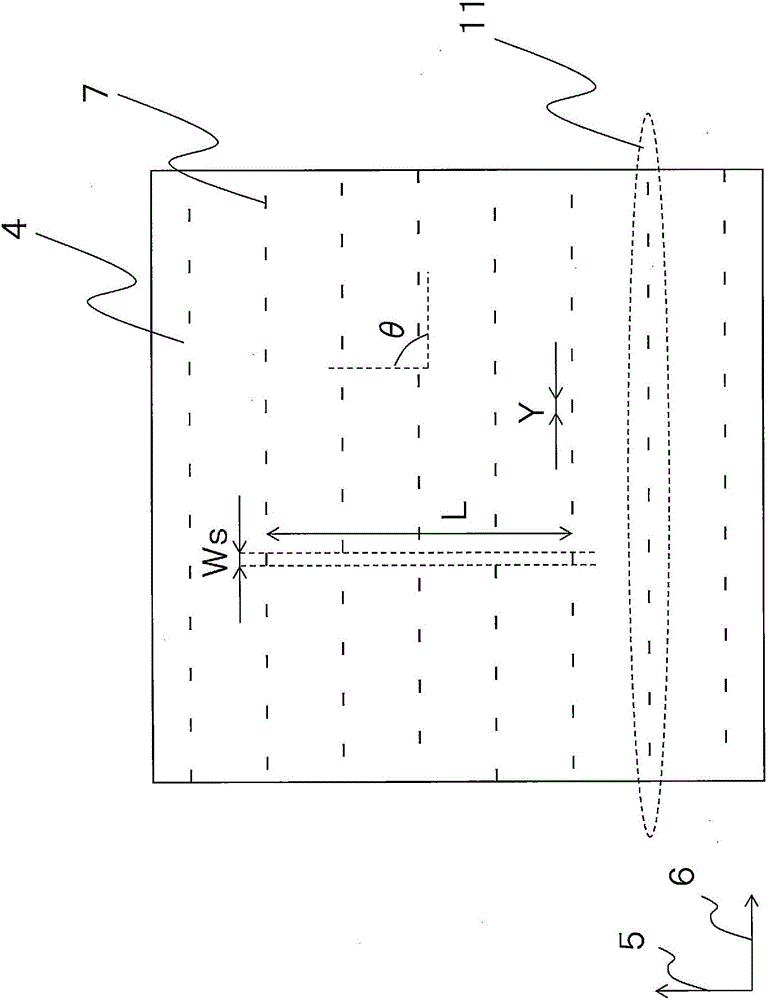

[0108] Toreka (registered trademark) prepreg P3252S-15 (reinforcing fiber: T700S, resin: 2592, volume content of reinforcing fiber: 56%, in A polyethylene film is laminated on one side, and a release paper is laminated on the other side) to make a notched prepreg sheet. Such as figure 2 As shown, the following pattern is formed, that is, slits are intermittently provided in the direction perpendicular to the reinforcement fiber, and the projected length Ws of the projection of the slit in the vertical direction of the reinforcement fiber is equal to the length Y of the slit, which is 1 mm. In the region surrounded by intermittent cuts in the longitudinal direction of the reinforcing fibers, substantially all of the reinforcing fibers were cut into reinforcing fibers having a fiber length L of 24 mm. A polyethylene film is pasted on the surface of the incision prepreg sheet, and when the prepreg is inserted into the incision along the fiber direction in the drum cutting machi...

Embodiment 3

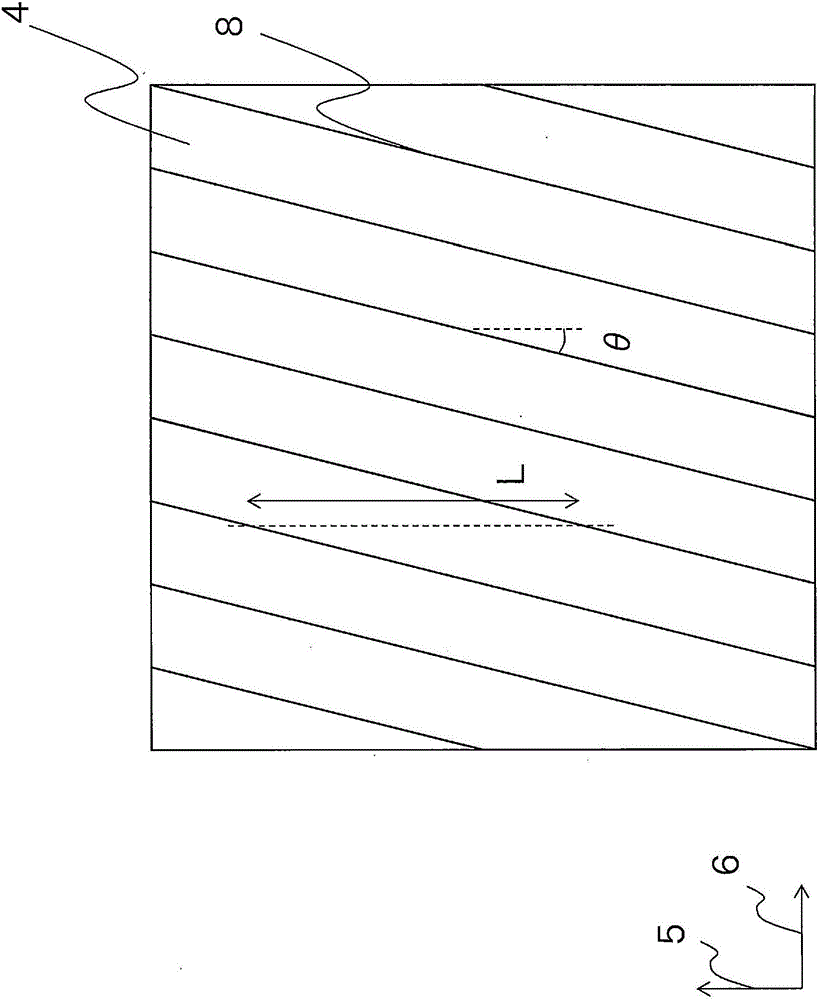

[0111] In addition to cutting patterns such as image 3 A notched prepreg sheet was manufactured in the same manner as in Example 2, except that the fiber length L was 24 mm, and the angle formed by the incision and the reinforcing fiber was 14° in a continuous cut pattern, and the same evaluation was performed. The handleability of the incision prepreg sheet is that since the polyethylene film is cut into short strips along the incision, only the polyethylene film sheet bonded by the scotch tape is peeled off. Polyethylene film sheets require work. The expansion rate of the notched prepreg molding is 2.1, and the surface quality of the expanded molded product is that fluctuations in the flow of fibers can be seen in addition to the opening of the notch. The mechanical properties of the expanded molded product were that the tensile modulus was 46 GPa and the tensile strength was 710 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com