Cable production equipment

A technology for producing equipment and cables, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems that single-strand or multi-strand cable carbon powder coaxial filling packaging can not be realized, and achieve high market promotion value, Good molding stability, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

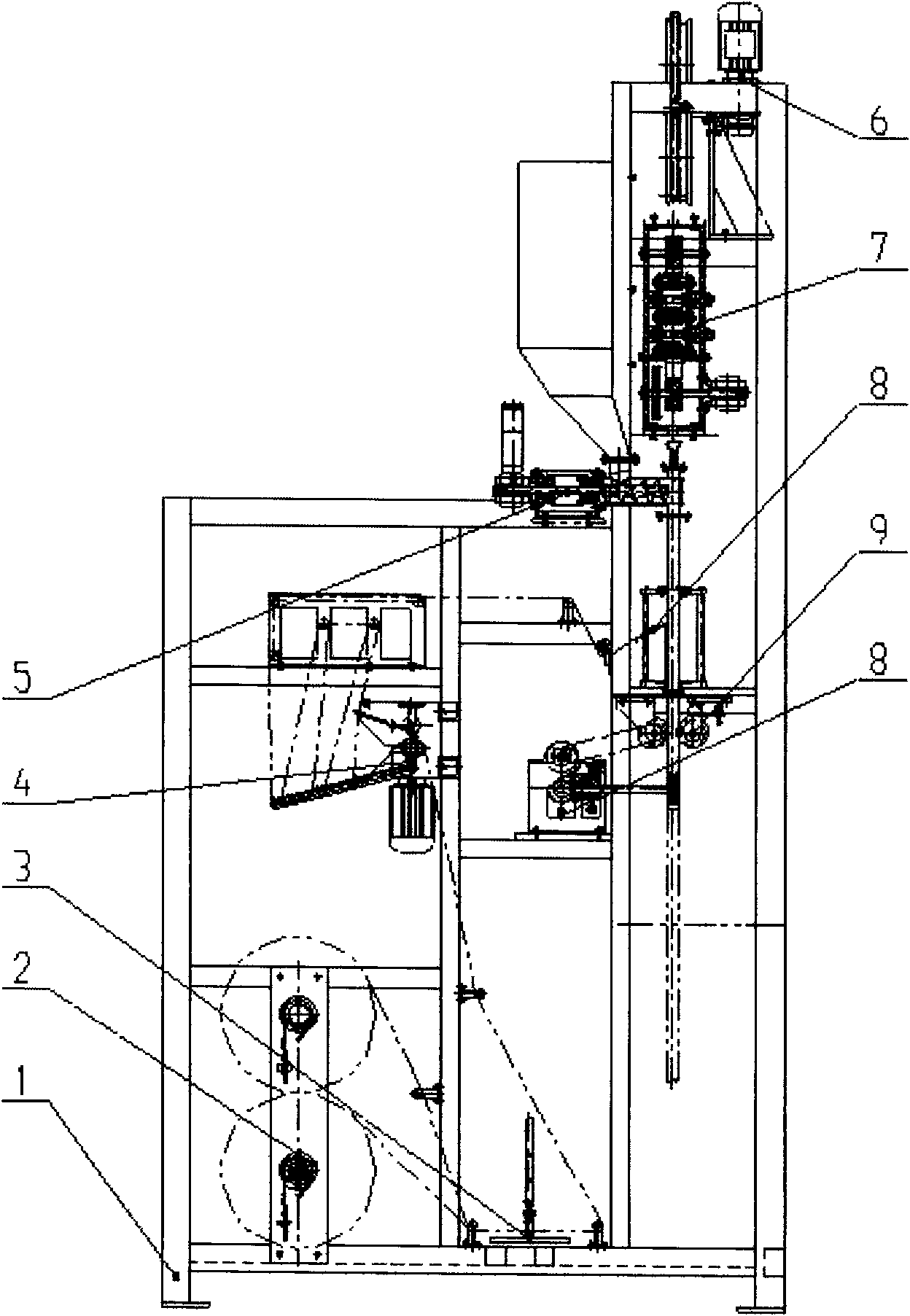

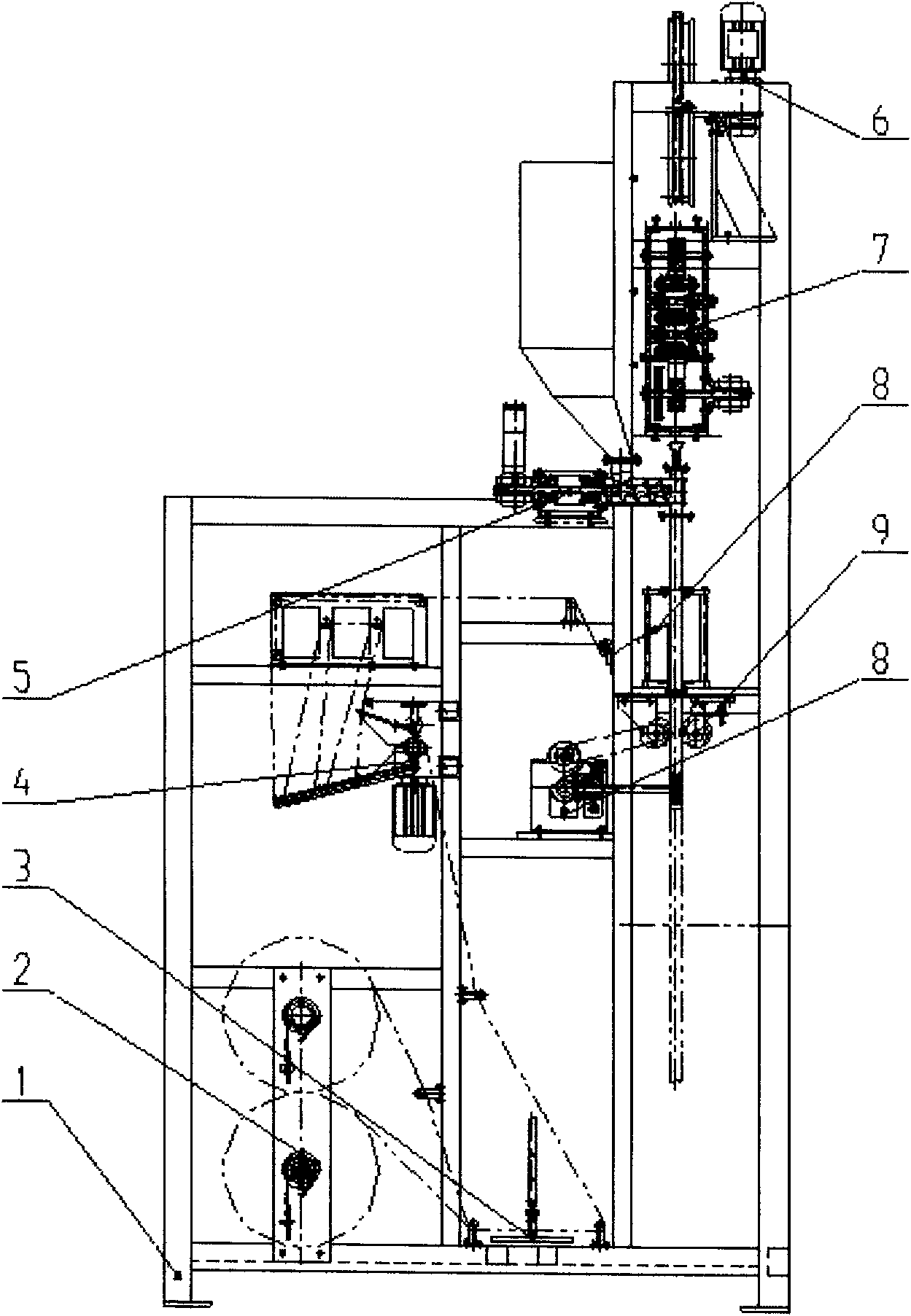

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] As shown in the accompanying drawings, a cable production equipment includes a mounting frame assembly 1, a wrapping material feeding mechanism 2, a wrapping material disconnecting mechanism 3, a wrapping material pre-drawing mechanism 4, a toner supply mechanism 5, The cable pre-drawing mechanism 6, the cable forming traction mechanism 7, the wrapping forming mechanism 8, the glue coating and rolling mechanism 9, and the forming traction mechanism 10 are all installed on the installation frame assembly 1, and the outlet of the wrapping coil feeding mechanism 2 The feed port is connected to the feed port of the wrapping material disconnection mechanism 3, and the discharge port of the wrapping material disconnection mechanism 3 passes through the first feeding port of the wrapping material pre-drawing mechanism 4, the cable pre-drawing mechanism 6 and the cable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com