Full-automatic composite hose making machine

A fully automatic, tube machine technology, applied to tubular objects, other household appliances, household appliances, etc., can solve the problems that the molding effect is difficult to maintain effectively and stably, cannot achieve continuous effect, and limits the production effect and production efficiency of composite hoses. , to achieve the effect of improving molding stability and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

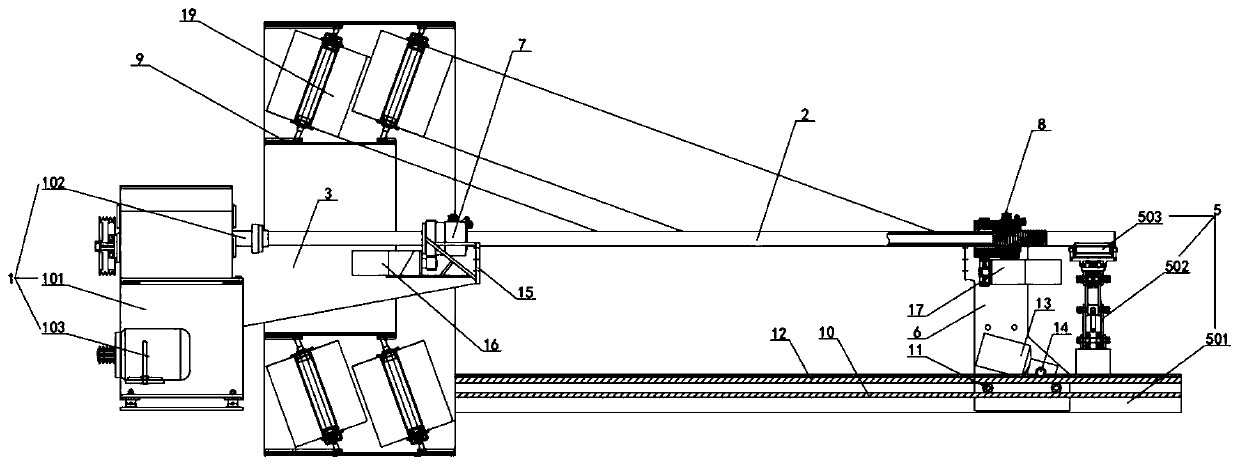

[0036] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments and the accompanying drawings:

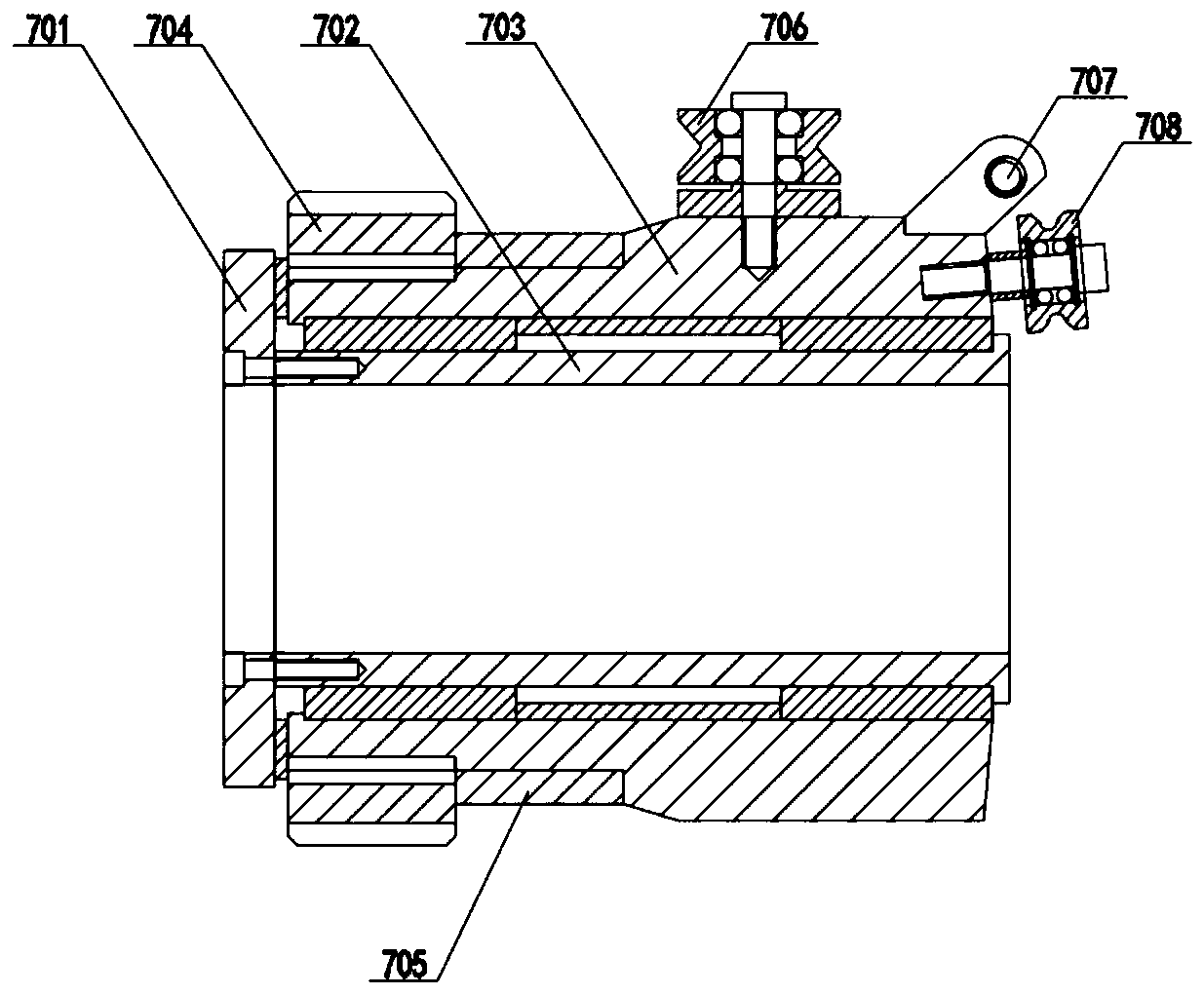

[0037] reference Figure 1-5 (For ease of presentation, figure 1 The base of the cloth film winding mechanism is not shown).

[0038] A fully automatic composite hose pipe making machine, including

[0039] The mandrel drive mechanism 1 is used to drive the mandrel mechanism 2. The mandrel drive mechanism 1 includes a mounting base 101, the upper part of the mounting base 101 is rotatably mounted with a drive shaft 102, and the drive shaft 102 is driven by a corresponding drive motor 103 for driving, the forward fixing device of the mounting seat 101 has an inner steel wire winding mechanism mounting plate 3;

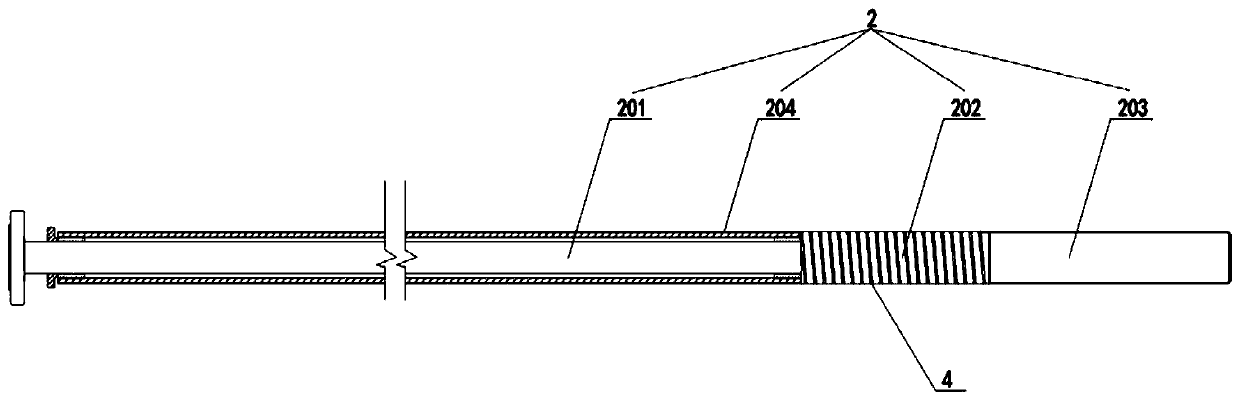

[0040] The mandrel mechanism 2 is arranged on the front side of the mounting seat 101. The mandrel mechanism 2 includes a mandrel body 201 that is drive-connected to the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com