Preparation method of ultra-pure tellurium

A technology of ultra-high and pure tellurium, which is applied in the field of preparation of ultra-high-purity tellurium, can solve the problems of high power consumption, low efficiency, and the inability of quartz boats to be sensed, and achieve the effect of bright surface and improved purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] This embodiment is an embodiment of the method for preparing ultra-high-purity tellurium of the present invention. The method for preparing ultra-high-purity tellurium in this embodiment includes the following steps:

[0031] (1) Soak the zone fused quartz boat with nitric acid and hydrofluoric acid mixed solution (nitric acid mass concentration 10% to 15%, hydrofluoric acid mass concentration 2 to 5%) for more than 8 hours to remove impurities on the surface. After soaking, use Clean it with pure water, and finally use the carbon coating furnace to perform coating operation on the surface of the fused quartz boat according to the carbon coating process;

[0032] (2) Clean the baffle quartz boat, zone fused quartz boat, zone fused graphite boat, zone furnace quartz tube, etc. with UP grade anhydrous ethanol and wipe clean with a dust-free cloth, and set aside;

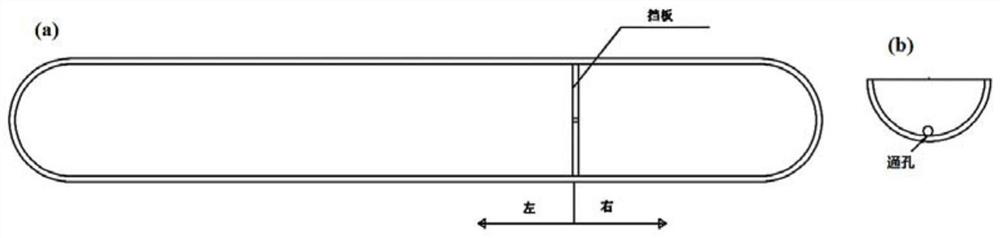

[0033] (3) Put 5N raw material tellurium into the baffle quartz boat (such as figure 1 shown) in the right c...

Embodiment 2

[0043] This embodiment is an embodiment of the method for preparing ultra-high-purity tellurium of the present invention. The method for preparing ultra-high-purity tellurium in this embodiment includes the following steps:

[0044] (1) Soak the zone fused quartz boat with nitric acid and hydrofluoric acid mixed solution (nitric acid mass concentration 10% to 15%, hydrofluoric acid mass concentration 2 to 5%) for more than 8 hours to remove impurities on the surface. After soaking, use Clean it with pure water, and finally use the carbon coating furnace to perform coating operation on the surface of the fused quartz boat according to the carbon coating process;

[0045] (2) Clean the baffle quartz boat, zone fused quartz boat, zone fused graphite boat, zone furnace quartz tube, etc. with UP grade anhydrous ethanol and wipe clean with a dust-free cloth, and set aside;

[0046] (3) Put 5N raw material tellurium into the baffle quartz boat (such as figure 1 shown) in the right c...

Embodiment 3

[0056] This embodiment is an embodiment of the method for preparing ultra-high-purity tellurium of the present invention. The method for preparing ultra-high-purity tellurium in this embodiment includes the following steps:

[0057] (1) Soak the zone fused quartz boat with nitric acid and hydrofluoric acid mixed solution (nitric acid mass concentration 10% to 15%, hydrofluoric acid mass concentration 2 to 5%) for more than 8 hours to remove impurities on the surface. After soaking, use Clean it with pure water, and finally use the carbon coating furnace to perform coating operation on the surface of the fused quartz boat according to the carbon coating process;

[0058] (2) Clean the baffle quartz boat, zone fused quartz boat, zone fused graphite boat, zone furnace quartz tube, etc. with UP grade anhydrous ethanol and wipe clean with a dust-free cloth, and set aside;

[0059] (3) Put 5N raw material tellurium into the baffle quartz boat (such as figure 1 shown) in the right c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com