Method for preparing hydrophobic coating through liquid material thermal spraying

A hydrophobic coating and thermal spraying technology, which is applied to coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve the problems of high cost, many steps and complicated procedures of fluoropolymer coating, and achieve The effect of low equipment cost, broad application prospects and economic benefits, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

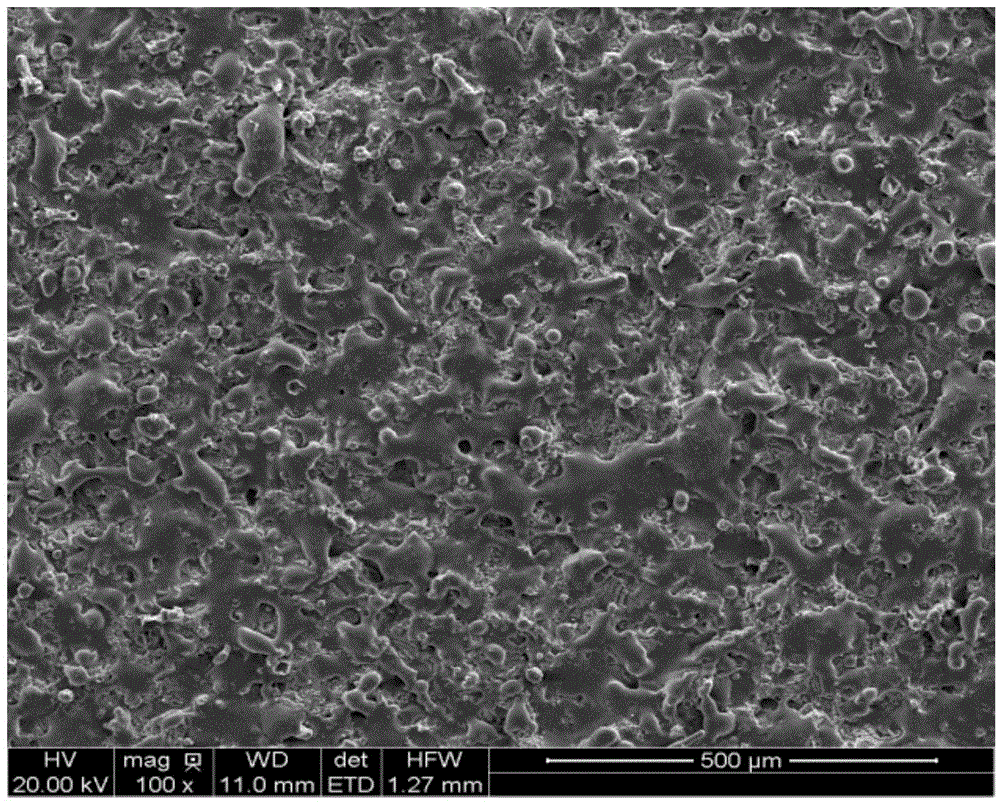

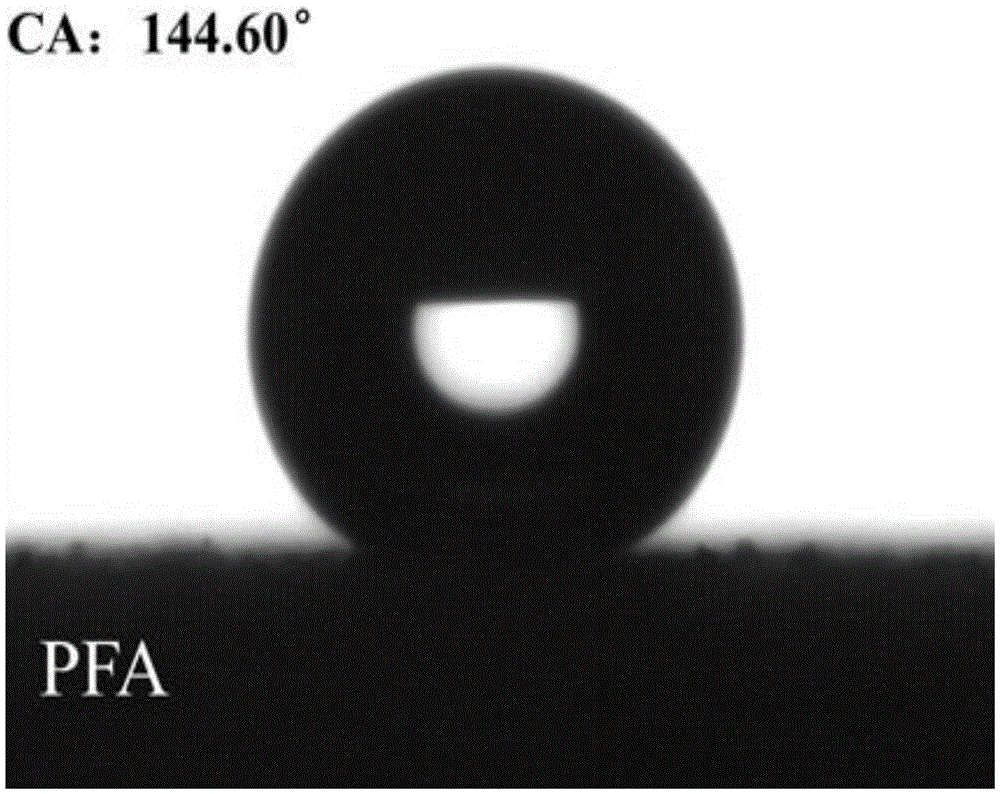

[0035] In this embodiment, the substrate material is a 1050 aluminum alloy sheet with a thickness of about 2mm, the thickness of the PFA coating on the surface of the substrate is 300 μm, and the coating is well combined with the substrate material; the specific preparation method of the hydrophobic coating is as follows:

[0036]1. Add PFA particles into ethanol solvent, and stir under magnetic stirring conditions to obtain a suspension, the mass percentage of the suspension particles in the solvent is 30%, and the particle diameter of the suspension particles is 30 μm.

[0037] 2. Clean the substrate with acetone, hydrochloric acid, and deionized water in sequence, and use 60-mesh brown corundum sand to roughen the surface of the 1050 aluminum alloy sheet. The air pressure used for sandblasting is 0.5MPa and 0.3MPa respectively, so that Roughness meets spraying requirements;

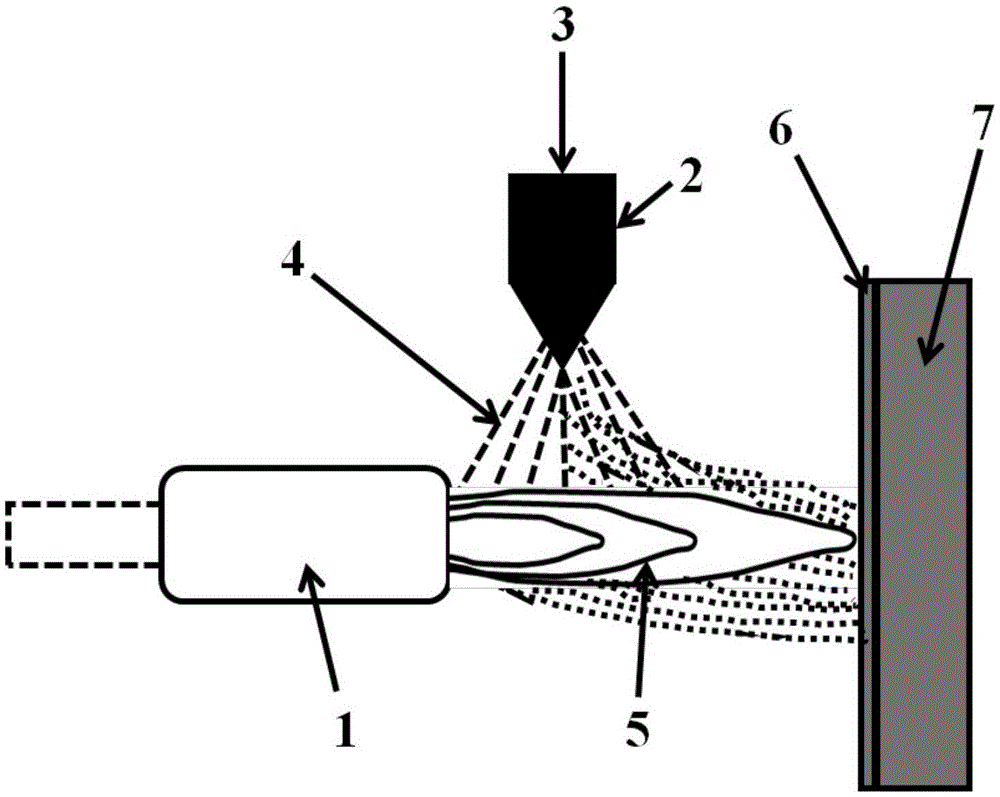

[0038] 3. If figure 1 As shown, the liquid material flame spraying method is adopted, the prepared...

Embodiment 2

[0043] In this embodiment, the substrate material is a 1060 aluminum alloy sheet with a thickness of about 2mm, the thickness of the PFA coating on the surface of the substrate is 100 μm, and the coating is well combined with the substrate material; the specific preparation method of the hydrophobic coating is as follows:

[0044] 1. Add PFA particles into ethanol solvent, stir under magnetic stirring conditions to obtain a suspension, the mass percentage of the suspension particles in the solvent is 10%, and the particle diameter of the suspension particles is 10 μm.

[0045] 2. Clean the substrate with acetone, hydrochloric acid, and deionized water in sequence, and use 60-mesh brown corundum sand to roughen the surface of the 1060 aluminum alloy sheet. The air pressure used for sandblasting is 0.5MPa and 0.3MPa respectively, so that Roughness meets spraying requirements;

[0046] 3. Adopt the liquid material flame spraying method, use the prepared suspension as the spraying...

Embodiment 3

[0051] In this embodiment, the substrate material is a 1070 aluminum alloy sheet with a thickness of about 2mm, the thickness of the PFA coating on the surface of the substrate is 600 μm, and the coating is well combined with the substrate material; the specific preparation method of the hydrophobic coating is as follows:

[0052] 1. Add PFA particles into ethanol solvent, stir under magnetic stirring conditions to obtain a suspension, the mass percentage of the suspension particles in the solvent is 50%, and the particle diameter of the suspension particles is 80 μm.

[0053] 2. Clean the substrate with acetone, hydrochloric acid, and deionized water in sequence, and use 60-mesh brown corundum sand to roughen the surface of the 1070 aluminum alloy sheet. The air pressure used for sandblasting is 0.5MPa and 0.3MPa respectively, so that Roughness meets spraying requirements;

[0054] 3. Adopt the liquid material flame spraying method, use the prepared suspension as the spraying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com