Porous carbon material taking polyvinylidene fluoride as precursor and preparation method

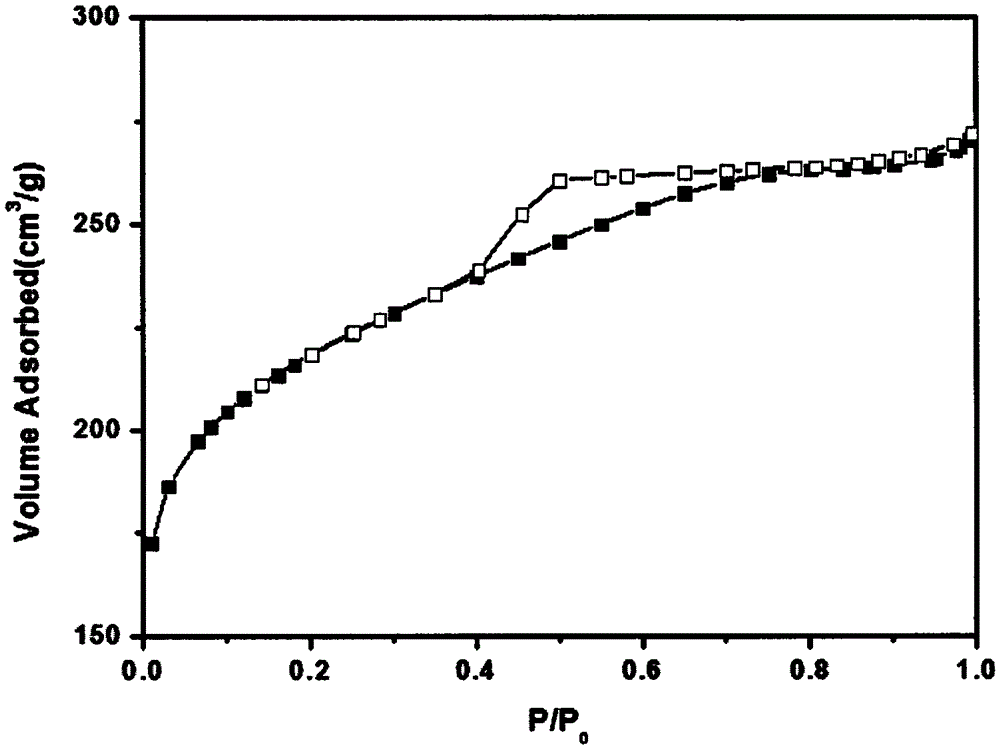

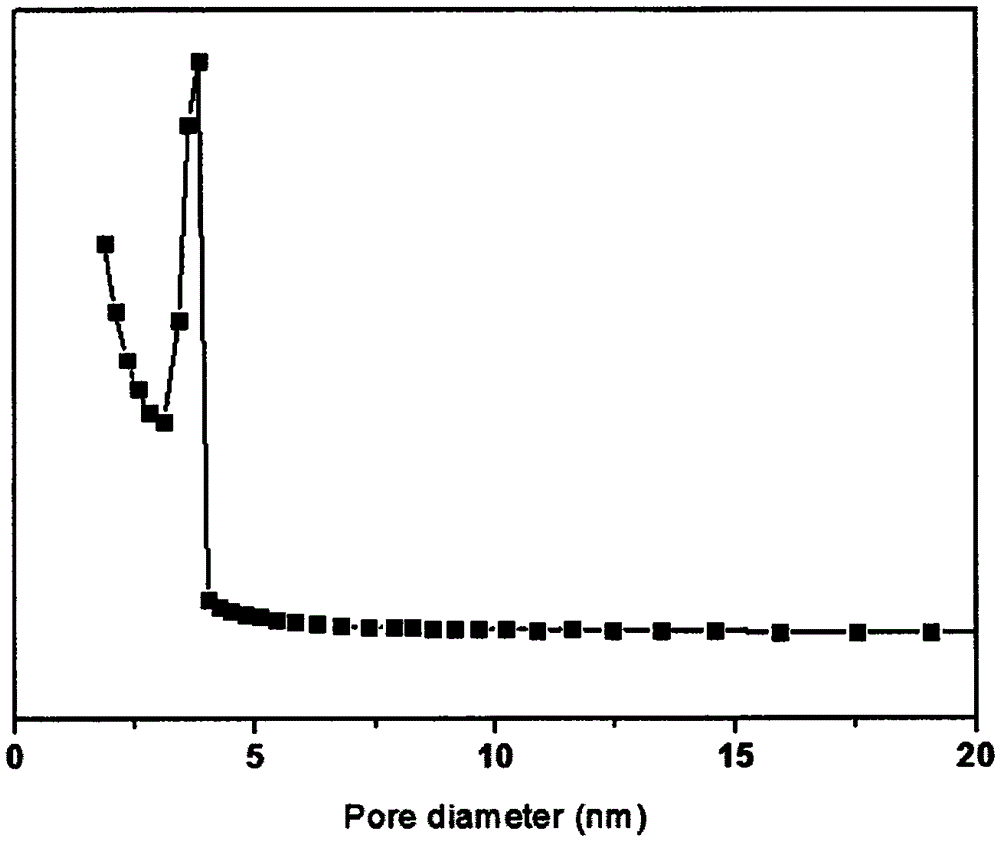

A polyvinylidene fluoride and porous carbon material technology, which is applied in the field of porous carbon material production, can solve the problems of cumbersome steps, complicated operation process of template method, limited large-scale application, etc., and achieves the effects of uniform pore size distribution and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add quantitative 6.67g of polyvinylidene fluoride to 20mL of dimethylacetamide, add 2.0g of polyvinylpyrrolidone, and stir at 60°C for 12 hours until the polymer and surfactant are completely dissolved and a transparent solution is obtained . Cast the solution on a clean, anhydrous watch glass, and dry the solvent in a blast oven at 40°C. A clear yellow film was formed.

[0016] Cut the above-mentioned polyvinylidene fluoride precursor material into small thin strips with scissors, weigh about 2.0g, put it into a porcelain boat, and put it into a tube furnace with a quartz tube, so that the sample is in the effective heating area, and the entire gas is sealed. After ensuring that the system has good airtightness, close the valve, use a vacuum pump to pump the air in the tube furnace until it is negative pressure (-1MPa), and then close the vacuum valve. Open the valve for feeding nitrogen, open the nitrogen bottle and let nitrogen flow at room temperature until the pr...

Embodiment 2

[0018] Add quantitative 5.0g of polyvinylidene fluoride to 20mL of N-methylpyrrolidone, and add 1.0g of polyethylene glycol (molecular weight: 6000), and stir at 75°C for 12 hours until completely dissolved and uniform to obtain a transparent solution. Cast the solution on a clean, anhydrous watch glass, and dry the solvent in a blast oven at 40°C. A clear yellow film was formed.

[0019] Cut the above-mentioned polyvinylidene fluoride precursor material into small thin strips with scissors, weigh about 2.0g, put it into a porcelain boat, and put it into a tube furnace with a quartz tube, so that the sample is in the effective heating area, and the entire gas is sealed. After ensuring that the system has good airtightness, close the valve, use a vacuum pump to pump the air in the tube furnace until it is negative pressure (-1MPa), and then close the vacuum valve. Open the valve for feeding nitrogen, open the nitrogen bottle and let nitrogen flow at room temperature until the ...

Embodiment 3

[0021] Add quantitative 8.0g polyvinylidene fluoride to 20mL dimethylformamide, add 4.0g polyvinylpyrrolidone, and stir at 70°C for 12 hours until the polymer and surfactant are completely dissolved and a transparent solution is obtained . Cast the solution on a clean, anhydrous watch glass, and dry the solvent in a blast oven at 40°C. A clear yellow film was formed.

[0022] Cut the above-mentioned polyvinylidene fluoride precursor material into small thin strips with scissors, weigh about 2.0g, put it into a porcelain boat, and put it into a tube furnace with a quartz tube, so that the sample is in the effective heating area, and the entire gas is sealed. After ensuring that the system has good airtightness, close the valve, use a vacuum pump to pump the air in the tube furnace until it is negative pressure (-1MPa), and then close the vacuum valve. Open the valve for feeding nitrogen, open the nitrogen bottle and let nitrogen flow at room temperature until the pressure ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com