Corrosion-resistant waterborne conductive paint and preparation method thereof

A conductive coating and corrosion-resistant technology, applied in conductive coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor corrosion resistance of water-based coatings, and achieve the effects of excellent organic solvent resistance, good conductivity and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

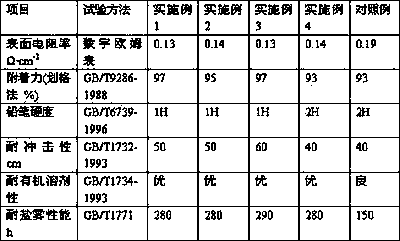

Examples

Embodiment 1

[0028] Weigh the following raw materials:

[0029] Silver powder 50Kg, graphite 10Kg, copper powder 3Kg, epoxy resin E-51 40Kg, silicone resin 10Kg, benzyl dimethyl ketal 3Kg, phenyl ethyl acrylate 3Kg, 1,6-hexanediol acrylate 2Kg, stearic acid amine 3Kg, diethylene glycol monohexyl ether 2Kg, polyoxypropylene triol 3Kg, cetyltrimethylammonium bromide 1Kg, isooctyl oleate 2Kg, calcium silicate 10Kg, bentonite 12Kg , polyvinyl alcohol aqueous solution 20Kg, ammonia water 15Kg, preservative 3Kg, ammonium dodecylbenzenesulfonate 2Kg, hydroxymethyl cellulose 5Kg, water 60Kg.

[0030] The above-mentioned silver powder adopts flake-shaped silver powder, the particle size is between 300-500nm, the particle size of graphite is between 200-300nm, the particle size of copper powder is preferably between 100-200nm, and the mass concentration of ammonia water is 30 %, the mass concentration of polyvinyl alcohol aqueous solution is preferably 10%, the preservative is isothiazolinone, and ...

Embodiment 2

[0037] Weigh the following raw materials:

[0038] Silver powder 60Kg, graphite 20Kg, copper powder 5Kg, epoxy resin E-51 50Kg, silicone resin 15Kg, benzyl dimethyl ketal 6Kg, phenyl ethyl acrylate 7Kg, 1,6-hexanediol acrylate 4Kg, stearic acid amine 5Kg, diethylene glycol monohexyl ether 4Kg, polyoxypropylene triol 6Kg, cetyltrimethylammonium bromide 3Kg, isooctyl oleate 4Kg, calcium silicate 12Kg, bentonite 15Kg , polyvinyl alcohol aqueous solution 30Kg, ammonia water 20Kg, preservative 6Kg, ammonium dodecylbenzenesulfonate 4Kg, hydroxymethyl cellulose 8Kg, water 80Kg.

[0039] The above-mentioned silver powder adopts sheet-type silver powder, the particle size is between 300-500nm, the particle size of graphite is between 200-300nm, the particle size of copper powder is preferably between 100-200nm, and the mass concentration of ammonia water is 40 %, the mass concentration of polyvinyl alcohol aqueous solution is preferably 12%, the preservative is isothiazolinone, and th...

Embodiment 3

[0046] Weigh the following raw materials:

[0047] Silver powder 55Kg, graphite 15Kg, copper powder 4Kg, epoxy resin E-51 45Kg, silicone resin 12Kg, benzyl dimethyl ketal 4Kg, phenyl ethyl acrylate 6Kg, 1,6-hexanediol acrylate 3Kg, stearic acid amine 4Kg, diethylene glycol monohexyl ether 3Kg, polyoxypropylene triol 4Kg, cetyltrimethylammonium bromide 2Kg, isooctyl oleate 3Kg, calcium silicate 11Kg, bentonite 13Kg , polyvinyl alcohol aqueous solution 25Kg, ammonia water 17Kg, preservative 5Kg, ammonium dodecylbenzenesulfonate 3Kg, hydroxymethyl cellulose 7Kg, water 70Kg.

[0048]The above-mentioned silver powder adopts flake silver powder, the particle size is between 300-500nm, the particle size of graphite is between 200-300nm, the particle size of copper powder is preferably between 100-200nm, and the mass concentration of ammonia water is 35 %, the mass concentration of polyvinyl alcohol aqueous solution is preferably 11%, the preservative is isothiazolinone, and the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com