Rear surface protection sheet for solar cell module and solar cell module protected by such protection sheet

A solar cell and backside protection technology, applied in electrical components, applications, circuits, etc., can solve problems such as poor resistance to organic solvents, toxic fluorine gases, and poor economy, and achieve excellent resistance to organic solvents, excellent moisture resistance, and improved The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

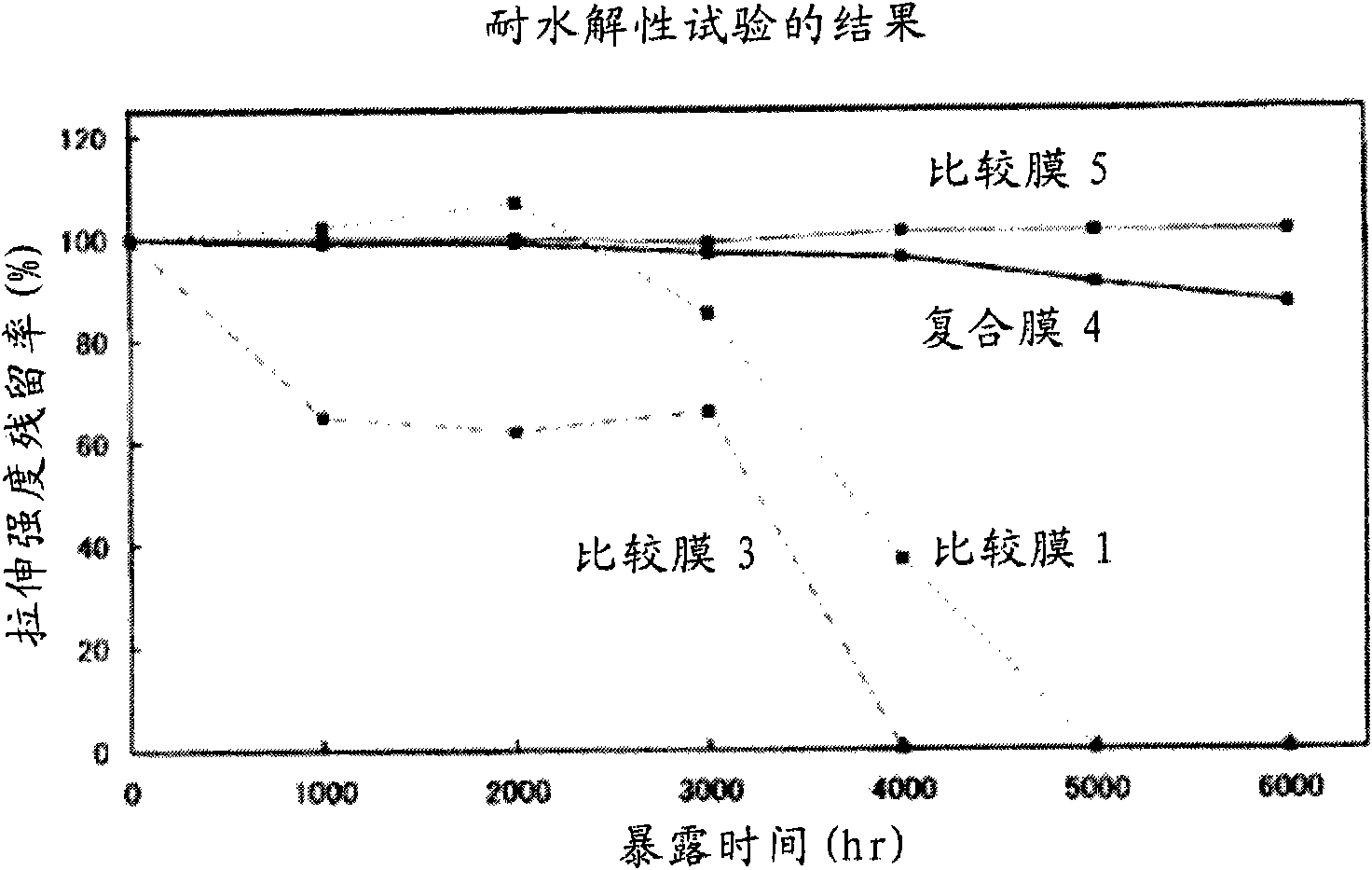

[0046] Production examples, examples and comparative examples of the present invention will be further described below.

[0047] The performances of the composite film and the back protection sheet were evaluated by the following methods. If the composite film is excellent in thermal shrinkage rate, hydrolysis resistance, and weather resistance, a back protection sheet having sufficient performance can be obtained.

[0048] [Heat shrinkage rate]

[0049] A test film with a length and width of 200×200 mm was heated at 150° C. for 30 minutes in a hot air dryer, and the heat shrinkage rate was measured. The thermal contraction rate in each vertical and horizontal direction was measured before and after heating, and the thermal contraction rate of the larger one was evaluated. If the thermal shrinkage rate is large, when the solar cell module is produced by hot pressing at 150°C, due to the large thermal shrinkage, there is a problem of damaging the copper wire connecting the so...

manufacture example

[0055] Polybutylene terephthalate (PBT, melting point: 225°C, intrinsic viscosity: 1.14) and polycarbonate (number average molecular weight: 25,000) were co-extruded using two types of three-layer T-die, and the following table was prepared Composite membrane shown in 1. And as a comparison, the films shown in Table 1 were produced also for PET, PBT, and PC. It should be noted that, in the composite film 6, titanium dioxide, which is a white pigment, was blended into the PC of the core layer to form a white film. Similarly, for Comparative Film 4, a white film was also produced. Table 1 shows the results of measuring the thermal shrinkage rate of the obtained film.

[0056] [Table 1]

[0057]

constitute

Thickness (μm)

Thickness composition ratio (%)

Heat shrinkage rate (%)

PBT / PC / PBT

100

25 / 50 / 25

0.22

PBT / PC / PBT

100

20 / 60 / 20

0.18

PBT / PC / PB...

Embodiment 1

[0065] [Example 1, Comparative Example 1]

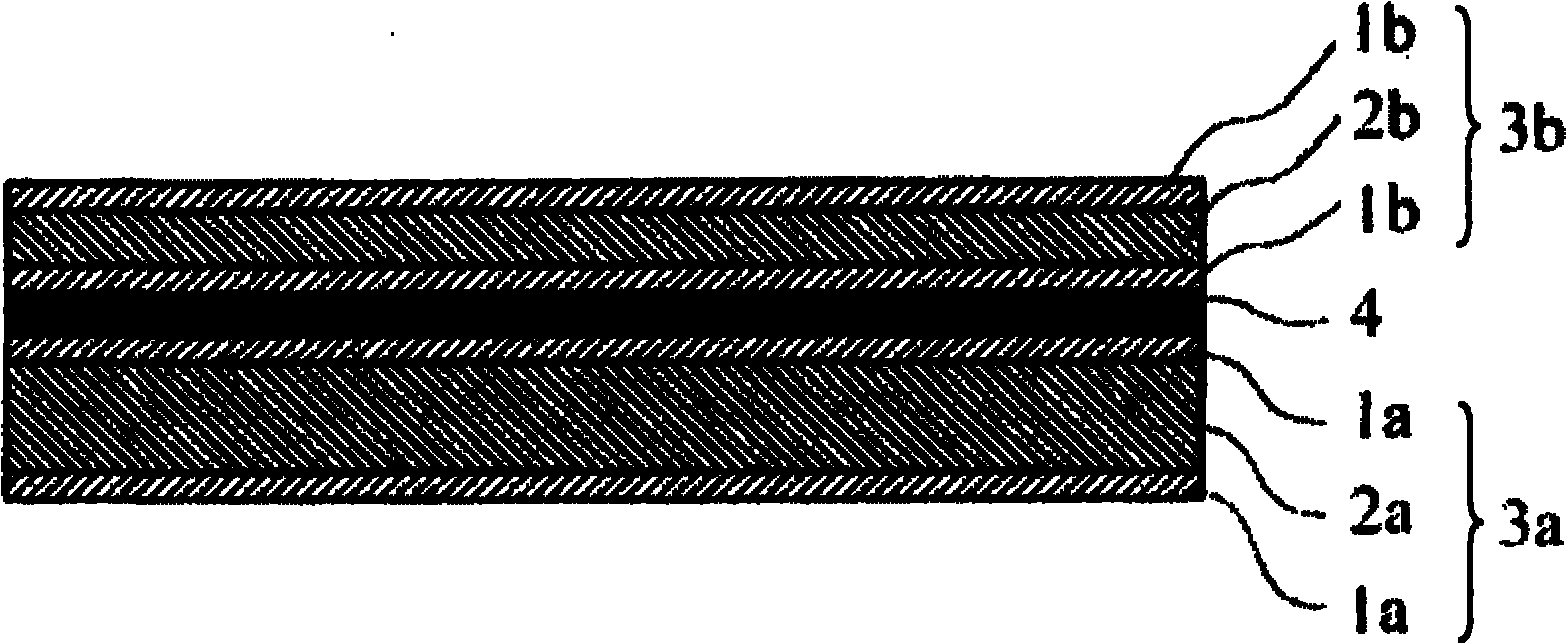

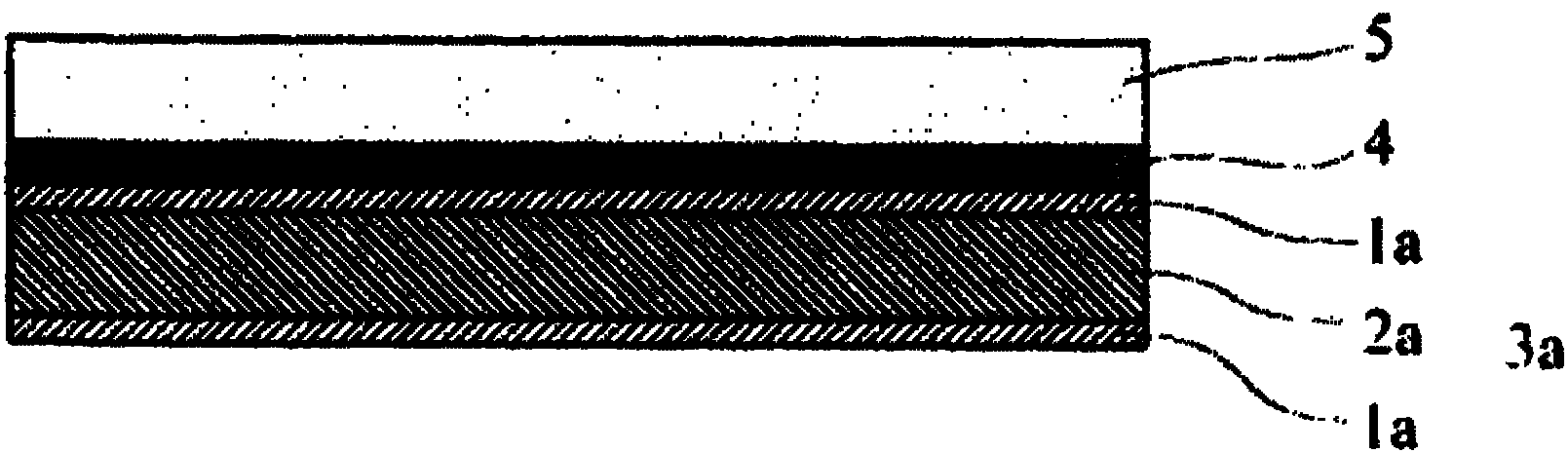

[0066] Silicon dioxide (SiO2) was evaporated on the surface of a PET film with a thickness of 12 μm 2 ) film (heat shrinkage rate: 1.18%) is used as a moisture-proof layer, and is laminated by dry lamination with a polyurethane adhesive to produce figure 1 The back protection sheet having the configuration shown above was used as Example 1. In addition, as Comparative Example 1, a PBT film (comparative films 2 and 4) was used instead of the composite film 4 to prepare a comparative back protection sheet. The heat shrinkage rate of the obtained back protection sheet is also shown in Table 3 similarly.

[0067] [table 3]

[0068]

constitute

Thickness (μm)

Heat shrinkage rate (%)

Example 1

Composite film 6 / moisture barrier / composite film 5

250

0.32

Comparative example 1

Comparative Membrane 4 / Moisture Barrier / Comparative Membrane 2

250

1.29

[0069] As shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com