Fluoride-free oil-proof paper as well as preparation method and application thereof

A technology for oil-proof paper and paper, applied in paper, papermaking, packaging paper, etc., can solve the problems of unsuitable industrial production and expensive raw materials, and achieve the effects of good mechanical properties, easy degradation and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

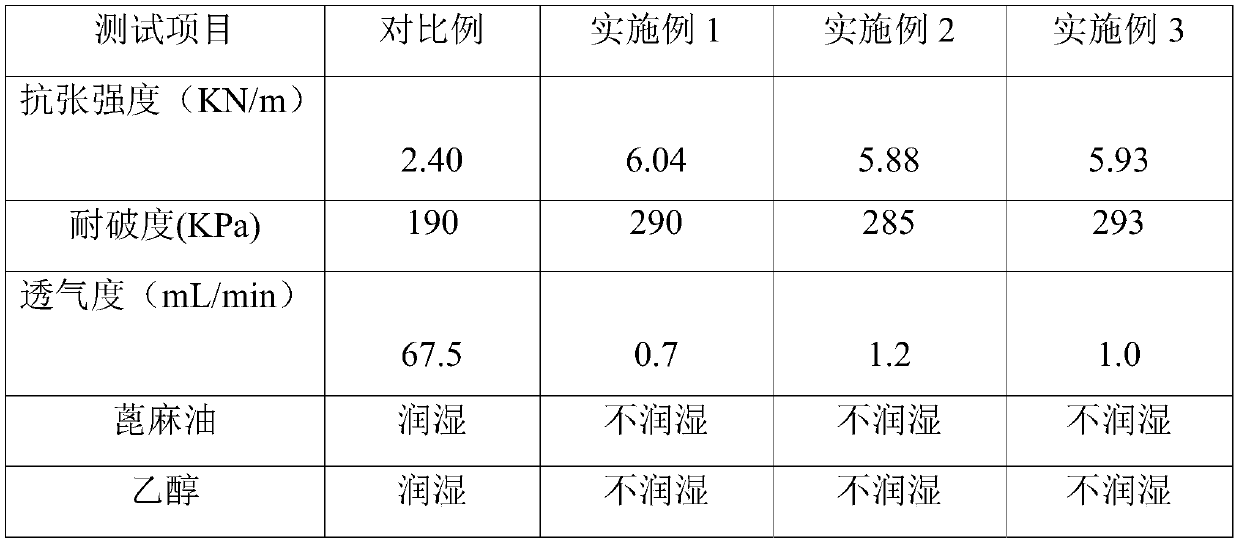

Examples

Embodiment 1

[0029] A preparation method of fluorine-free oil-proof paper, comprising the following steps:

[0030] (1) Sodium hydroxide, urea and water are mixed homogeneously, obtain sodium hydroxide / urea / water solution, the mass ratio of described sodium hydroxide, urea and water is 6:15:79, then described sodium hydroxide / The urea / water solution is subjected to pre-cooling treatment, the temperature of the pre-cooling treatment is -12°C, and the time of the pre-cooling treatment is 5 minutes to obtain a pre-cooled solution;

[0031] (2) 4g dissolving pulp (its cellulose content 95wt%) is added in the solution after the described pre-cooling of step (1), mix uniformly, obtain mixed solution, described mixed solution is carried out freezing treatment, described freezing treatment The temperature is -12°C, the freezing time is 12 hours, and then thawed at room temperature, centrifuged at a speed of 4000 rpm for 25 minutes, and the supernatant is taken to obtain the cellulose coating;

...

Embodiment 2

[0034] A preparation method of fluorine-free oil-proof paper, comprising the following steps:

[0035] (1) sodium hydroxide, urea and water are mixed homogeneously, obtain sodium hydroxide / urea / water solution, the mass ratio of described sodium hydroxide, urea and water is 8:12:80, then described sodium hydroxide / The urea / water solution is subjected to pre-cooling treatment, the temperature of the pre-cooling treatment is -20°C, and the time of the pre-cooling treatment is 10 minutes to obtain a pre-cooled solution;

[0036] (2) 4g of dissolving pulp (the cellulose content is 97%) is added in the solution after the pre-cooling described in step (1), mix uniformly, obtain mixed liquor, described mixed liquor is carried out freezing treatment, described freezing treatment The temperature is -20°C, the freezing time is 24 hours, then thawed at room temperature, centrifuged at 6000 rpm for 20 minutes, and the supernatant is taken to obtain the cellulose coating;

[0037] (3) the...

Embodiment 3

[0039] A preparation method of fluorine-free oil-proof paper, comprising the following steps:

[0040] (1) Sodium hydroxide, urea and water are mixed homogeneously, obtain sodium hydroxide / urea / water solution, the mass ratio of described sodium hydroxide, urea and water is 10:10:80, then described sodium hydroxide / urea The urea / water solution is subjected to pre-cooling treatment, the temperature of the pre-cooling treatment is -16°C, and the time of the pre-cooling treatment is 10 minutes to obtain the pre-cooled solution;

[0041] (2) 4g of dissolving pulp (the cellulose content is 99%) is added in the solution after the pre-cooling described in step (1), mix uniformly, obtain mixed liquor, described mixed liquor is carried out freezing treatment, described freezing treatment The temperature is -16°C, the freezing time is 18 hours, then thawed at room temperature, centrifuged at 8000 rpm for 15 minutes, and the supernatant is taken to obtain the cellulose coating;

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com