Method for preparing polyamide composite nanofiltration membrane based on green and environment-friendly ionic liquid

A composite nanofiltration membrane and ionic liquid technology, which is applied in the field of preparing polyamide composite nanofiltration membranes based on green and environment-friendly ionic liquids, can solve problems such as toxicity, environmental and human injury, and are not environmentally friendly, and achieves low vapor pressure and ease of use. Pollution and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for preparing a polyamide composite nanofiltration membrane based on a green environment-friendly ionic liquid comprises the following steps:

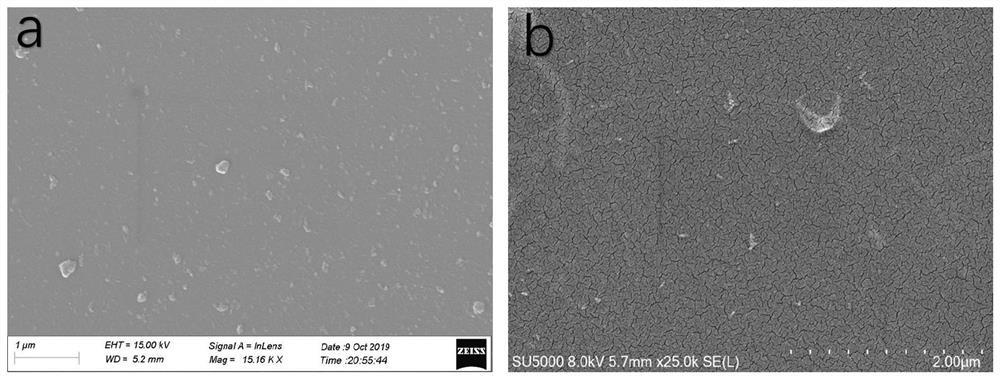

[0030] Step (1) adopts ionic liquid 1-ethyl-3-methylimidazole acetate as the solvent for dissolving polym-phenylene isophthalamide (i.e. PMIA), and forms a film-casting solution after dissolving to prepare PMIA porous base Membrane; the concentration of polymer PMIA in the casting solution is 16% w / v, and the average relative molecular mass of PMIA is 200000 (provided by Yantai Taihe New Materials Co., Ltd.). Among them, the porous base film can be produced by the following process: the casting solution is evenly scraped on the glass plate with an automatic scraper, the thickness of the scraper is 200 μm, and after standing in the air for 1 minute, the glass plate with the film solution is quickly and horizontally immersed in a water bath at room temperature , until the membrane was peeled off from the peeling substra...

Embodiment 2

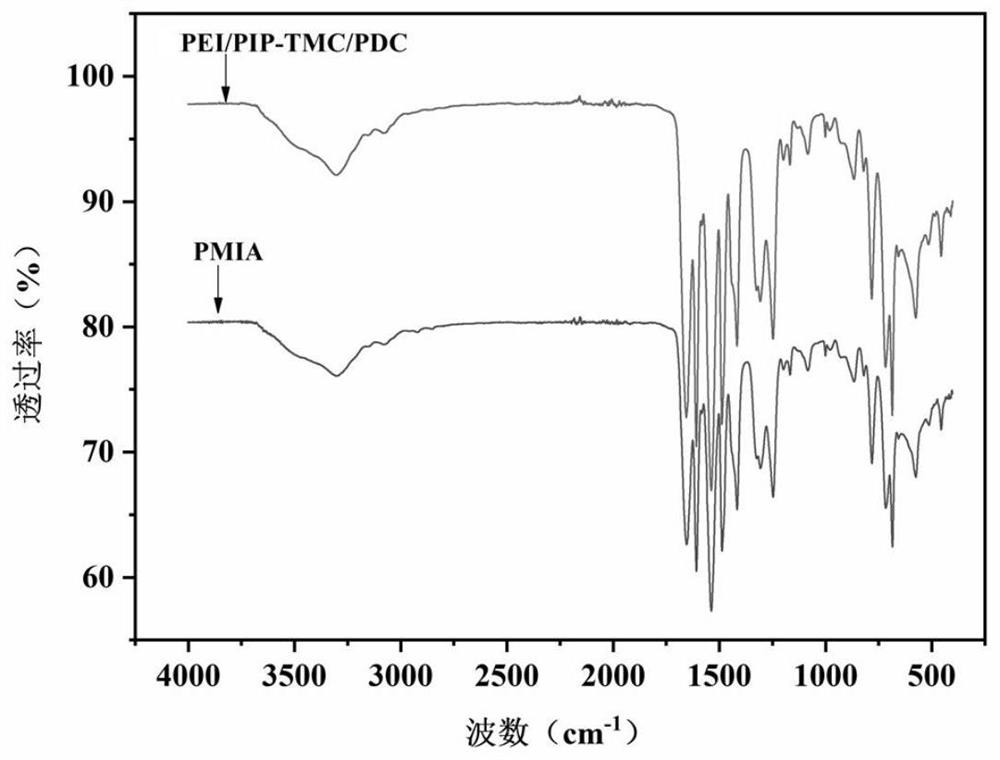

[0038] In step a of step (2) of embodiment 1, the ratio of polyethyleneimine (PEI), piperazine (PIP), and water is adjusted to 0.02g: 0.1g: 120g; In step c, the drying temperature and time are adjusted to 60° C. and 10 min; the rest of the process parameters are the same as in Example 1. The infrared spectrum of the prepared polyamide composite nanofiltration membrane is shown in the attached figure 2 As shown, the characterization data prove that we have successfully prepared a polyamide selective layer on the surface of PMIA porous base membrane. The prepared polyamide composite nanofiltration membrane was used in the membrane separation of Congo red dye / methanol solution for nanofiltration experiments using a dead-end filtration device. In the experiment, the membrane to be tested was pre-compressed under a certain pressure for a period of time, and after reaching a steady state, the nanofiltration experiment was performed and data was collected. The results showed that ...

Embodiment 3

[0040]In step a of step (2) of embodiment 1, the ratio of polyethyleneimine (PEI), piperazine (PIP), and water is adjusted to 0.02g: 0.2g: 100g; In step c, the drying temperature and time are adjusted to 70° C. and 8 min; the rest of the process parameters are the same as in Example 1. The prepared polyamide composite nanofiltration membrane was used in the membrane separation of rhodamine B dye / ethanol solution for nanofiltration experiments using a dead-end filtration device. In the experiment, the membrane to be tested was pre-compressed under a certain pressure for a period of time, and after reaching a steady state, the nanofiltration experiment was performed and data was collected. The results showed that the retention rate of rhodamine B dye was 99.8%, and the penetration amount reached 1.7L h -1 m -2 bar -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com