Patents

Literature

45results about How to "Good resistance to organic solvents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

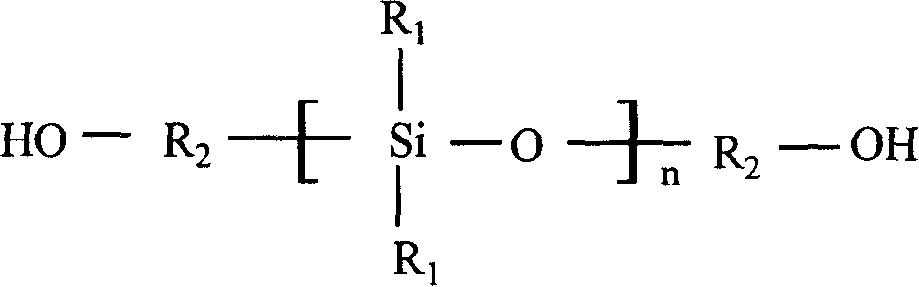

Modified epoxy resin adhesive and its preparation process

The invention relates to a modified epoxide resin adhesive agent and its preparation process to overcome the disadvantage such as brittleness and bad temperature resistance of common epoxide resin adhesive agents, which comprises: mixing the epoxide resin (component A) modified by polyurethane prepolymer and curing agent (component B) produced by author in the proportion of between 10:1 to 1:1 to prepare the curing system of fire resistant, good toughness and large reaction, wherein the polyurethane prepolymer is polysiloxane polyurethane prepolymer capped by isocyanate groups which are produced by the reaction of hydroxy-terminated polysiloxane and diisocyanate in a definite proportion, then using the said polyurethane prepolymer to modified treat epoxide resin. The said curing agent produced by author is made of diamine, imidazolinium compounds, silane coupling agents, mineral filler and catalyst. The said modified epoxide resin adhesive agent can be cured in room temperature and has the good characteristics of oil resistant, water resistant, acid and alkali resistant and resistance to organic solvent, also can adhere to the damp face, oil face, metal, plastic, ceramic, hard rubber and wood and so on.

Owner:李洁华

High-barrier layer flexible packaging film for isolating contents of polymer lithium battery

The invention provides a high-barrier layer flexible packaging film for isolating contents of a polymer lithium battery. The high-barrier layer flexible packaging film comprises at least two kinds of films which are combined to form a layer of composite film, wherein the composite film comprises a basic layer, a functional layer and a heat sealing layer; the high-barrier layer flexible packaging film is characterized in that: the basic layer is a copolymer film prepared by combining at least two film base materials of PP (polypropylene), CPP (chlorinated polypropylene or casting polypropylene), PE (polyethylene), PET (poly(ethylene terephthalate)), PA (polyamide) or MXD6 (aromatic polyimide), MPE (elastomer blend), PVDC (polyvinyl dichloride), EVOH (ethylene-vinyl alcohol), PEN (polyethylene naphthalate) and GT, or by complexing pairwise; and a high-barrier water-tolerant modified PVA (poly vinyl alcohol) coating film is coated on the copolymer film base materials. The high-barrier layer flexible packaging film has excellent gas barrier property, remarkably low oxygen permeability, water resistance, corrosion resistance, good high temperature resistance and great barrier property, and resists organic solvents and highly-volatile substances. In the invention, the high-barrier PVA is preferably coated on various base materials to obtain a base layer serving as a high-barrier layer which has great barrier property and excellent performance in resisting gas, water, corrosion, ultraviolet rays and the like.

Owner:刘继福

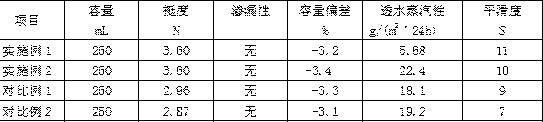

Venting, self-cleaning and degradable environmental-friendly preservative film and preparation method thereof

InactiveCN101817939AHigh tensile strengthImprove toughnessFlexible coversWrappersAntibiosisPolymer science

The invention discloses a venting, self-cleaning and degradable environmental-friendly preservative film and a preparation method thereof. Chitosan, nanometer titanium dioxide and beta-cyclodextrine serve as raw materials, and an ultrasonic wave blending compound technology and a freeze drying pore-forming technology are adopted to develop a novel bright and transparent degradable preservative film which has even thickness and totally satisfies the physical performance requirement of the preservative film. The method comprises the following steps: dispersing nanometer titanium dioxide, preparing mixed film liquid at a ratio, blending by ultrasonic wave, freezing, drying, baking and the like. Compared with the like product, the method of the invention is simple and easy to realize and has low preparation cost. The preservative film of the invention is degradable and has the functions of venting, antibiosis, self cleaning and the like, is a new-generation environmental-friendly preservative film for replacing the existing plastic preservative film, can be used for preserving fresh food and has wide application prospect and economic value in food field and the like.

Owner:徐紫宸

Anti-mosquito sustained-release cloth finishing method

ActiveCN102926201ARegular structureChemically stableVegetal fibresAnimal fibresCross-linkPolyvinyl alcohol

The invention relates to the field of functional textiles, and particularly relates to an anti-mosquito sustained-release cloth finishing method suitable for textile fabrics. The anti-mosquito agent microcapsules are attached to the fabric by a fixing agent, then cross-linked by a crosslinking agent and dehydrated and dried to directly obtain anti-mosquito sustained-release cloth without roasting; the fixing agent is polyvinyl alcohol or a modified polyvinyl alcohol compound; and the crosslinking agent is boric acid. The finishing method is simple, short in flow, easy to operate and low in cost. The finished anti-mosquito sustained-release cloth has a quick and efficient killing effect on mosquitoes and realizes a good mosquito repelling effect. After anti-mosquito finishing, the fabric is safe and harmless to a human body, and the appearance and physical index are not influenced.

Owner:FUZHOU UNIV

Making process and product of color vaccum aluminium plating paper as package material

InactiveCN1417415AImprove the finishGood resistance to organic solventsFlexible coversWrappersPaper sheetChemistry

In the present invention, polyester film is painted with easy-to-peel coating, sprayed with aluminium and adhered with paper layer, and the polyester film is then peeled and paint containing pigment is painted to the easy-to-peel coating to obtain the product. The easy-to-peel coating consists of nitro cellulose and acrylic resin. The improved easy-to-peel coating has raised organic solvent resistance, can be colored in great area, and is covered with rougher easy-to-peel layer and thus has high smoothness and mirror effect. The aluminum-plating paper can be printed and colored in controlled color difference.

Owner:汕头市绿新企业咨询有限公司

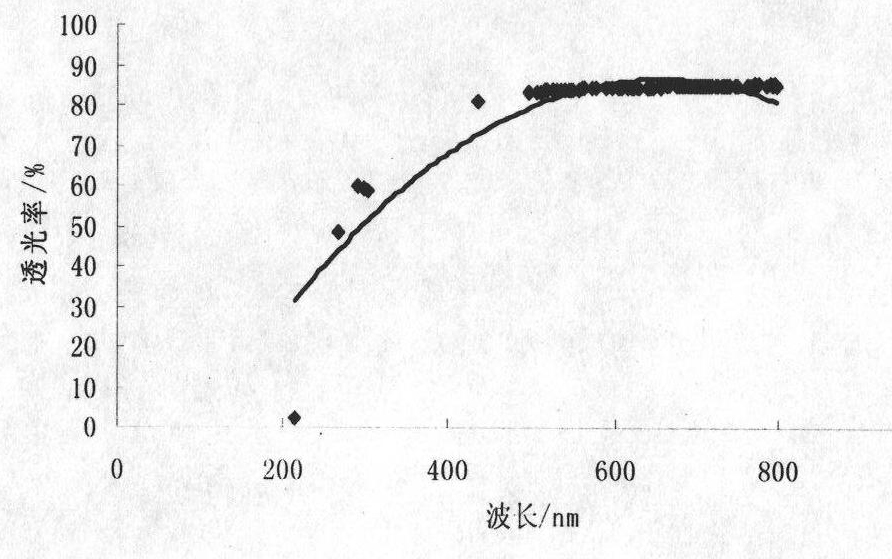

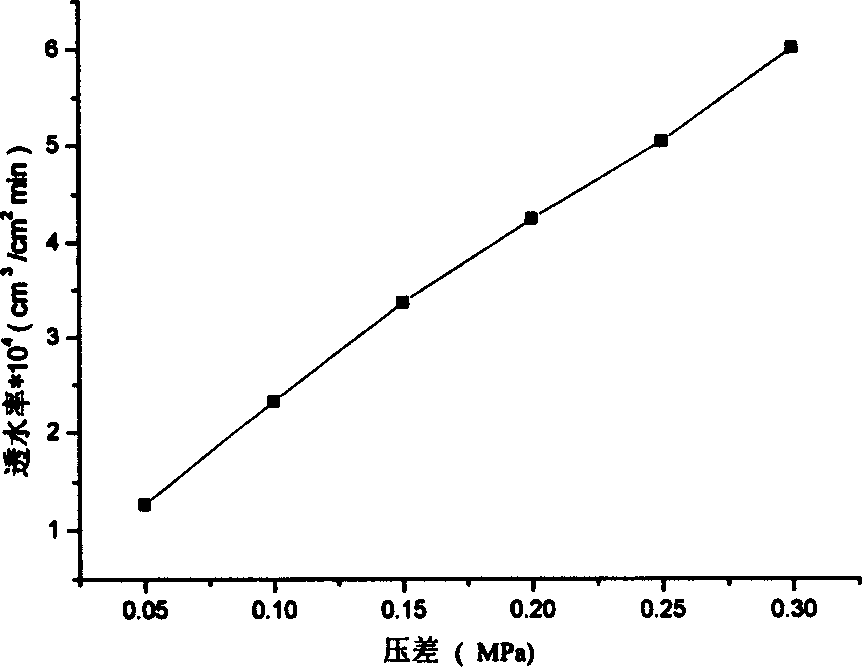

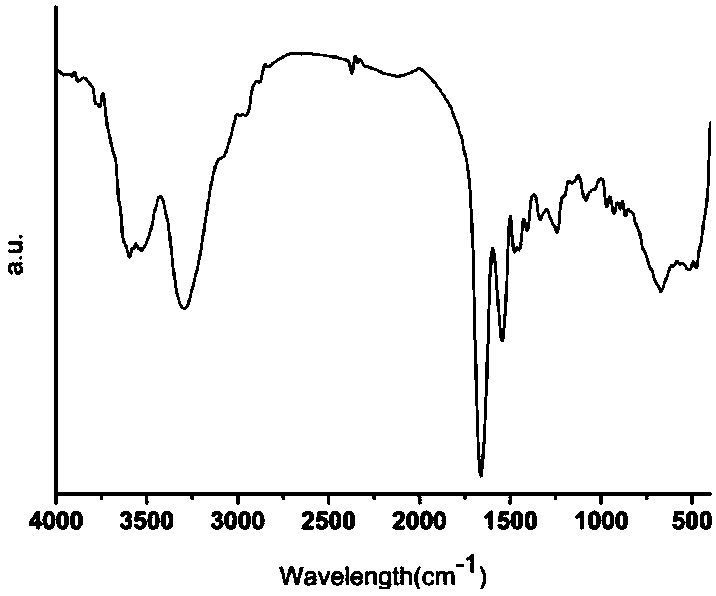

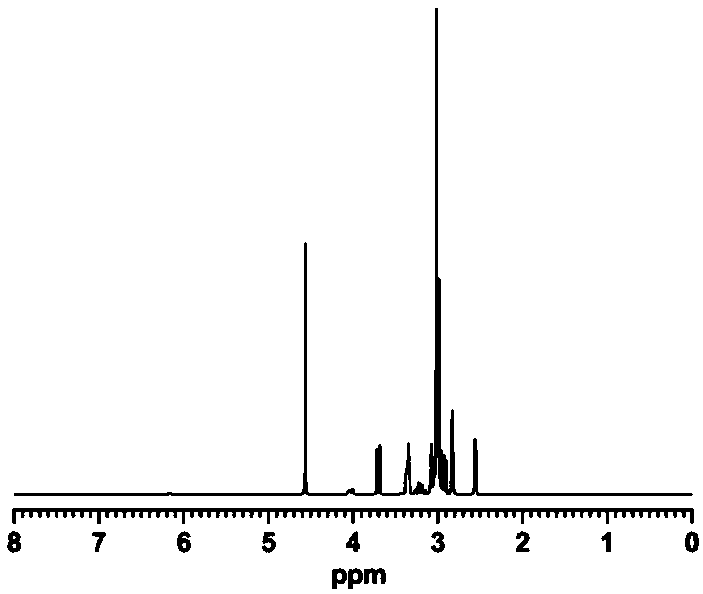

Preparation and usage of hollow cellulose gas humidification membrane

InactiveCN1621136AProtective propertiesProtect biocompatibilitySemi-permeable membranesCell electrodesHollow fibrePolymer science

The hollow cellulose fiber gas humidifying membrane is homogeneous compact structure prepared through direct dissolving cellulose with N-methyl morpholine monohydrate as solvent and spinning vian immersing phase converting process. The preparation process includes: dissolving cellulose with 80-93 % concentration MMNO.H2O at 80-110 deg.c and debubbling to obtain membrane forming liquid of 7-20 wt% cellulose concentration; spinning hollow membrane through immersing phase converting process; washing to eliminate residual solvent in the membrane; and drying naturally to obtain dry hollow membrane. The cellulose fiber gas humidifying membrane thus prepared has high crystallization degree, high mechanical strength, high organic solvent, acid and alkali resistance, high water penetrating capacity, and small oxygen and hydrogen osmosing coefficient, and is very suitable for use in gas humidifying system in fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Gas separation film made of cellulosic hollow fiber and the preparation process thereof

InactiveCN1485125AGood osmotic separation performanceProtective propertiesSemi-permeable membranesDispersed particle separationFiberPolymer science

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

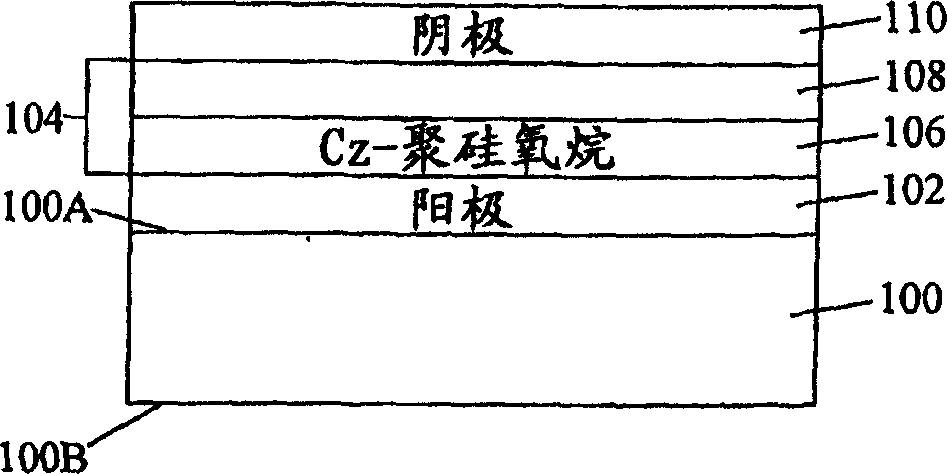

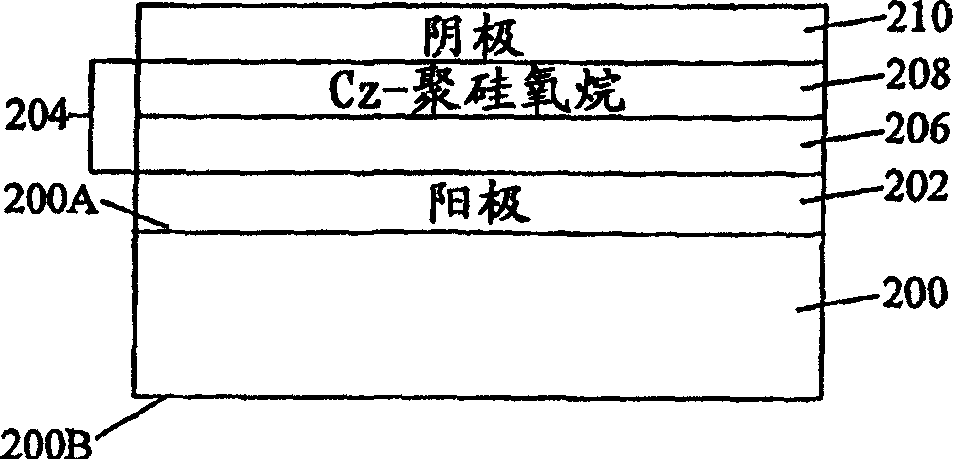

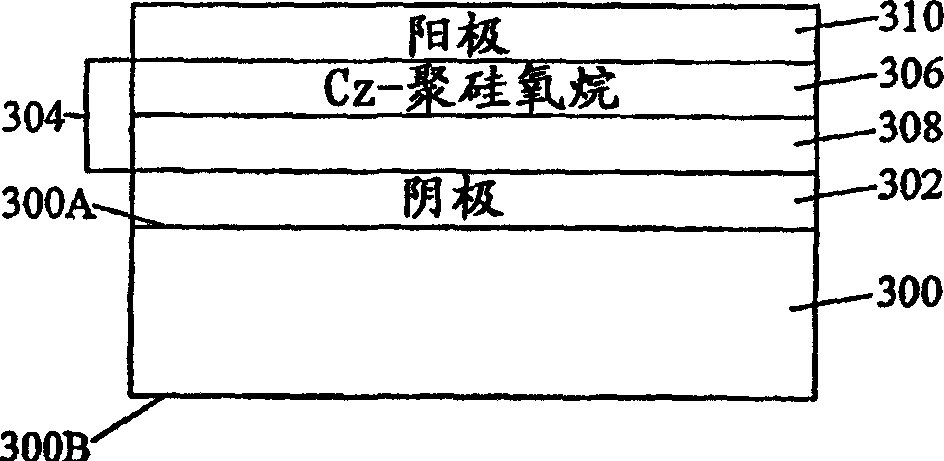

Carbazolyl-functional linear polysiloxanes, silicone composition, and organic light-emitting diode

InactiveCN1839173AHigh electroluminescence efficiencyGood storage stabilityStatic indicating devicesElectroluminescent light sourcesSiloxanePolymer chemistry

Carbazolyl-functional linear polysiloxanes containing N-carbazolylalkyl groups and hydrolysable groups, a silicone composition containing a carbazolyl-functional linear polysiloxane, a curd carbazolyl-functional polysiloxane prepared by curing the silicone composition, and an organic light-emitting diode (OLED) containing a carbazolyl-functional polysiloxane.

Owner:DOW CORNING CORP

Preparation method of bamboo fiber paper cups

InactiveCN108824071AGood oil resistanceGood resistance to organic solventsPaper coatingReinforcing agents additionPolypropyleneGuar gum

The invention discloses a preparation method of bamboo fiber paper cups. The invention relates to a bamboo fiber paper cup and a production process thereof. The bamboo fiber paper cup mainly structurally comprises a hollow fiber cup body, and is characterized in that the cup body comprises an outer layer, an inner layer, a hollow layer arranged between the outer layer and the inner layer and a coating layer above the inner layer. The outer layer and the inner layer are prepared from the following components in parts by weight: bleached bamboo fibers, dahurian larch fibers, modified starch, chitosan, talc powder, a dispersant, guar gum, glyceride hydrolase and a wet-strength agent. The hollow layer is prepared from the following components in parts by weight: polypropylene hollow short fiber pulp, dahurian larch fibers, chitosan, talc powder and a dispersant. According to the above settings, the outer layer and the inner layer are produced by employing bamboo fibers. The bamboo fiber pulp not only is environment-friendly, but also has the characteristics of being excellent in antibacterial property, bacteriostatic and free of peculiar smells. The hollow fiber layer has the functionsof being light in weight, heat insulative and warm-keeping. The bamboo fiber paper cup serving as a hot drink paper cup and a cold drink paper cup simultaneously is relatively safe.

Owner:安徽永豪新材料科技有限公司

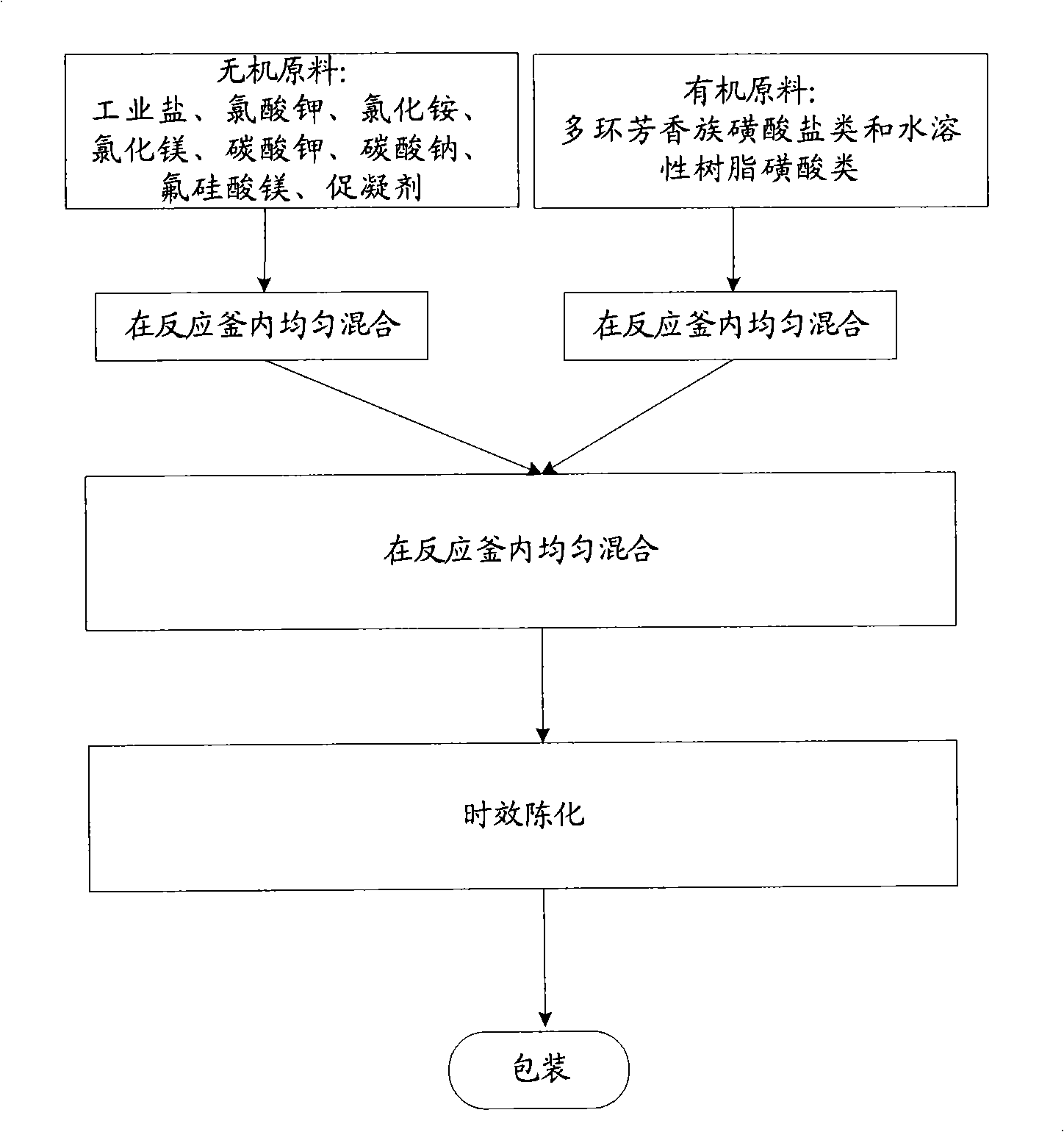

Solidifying agent used as solid castoff concrete and preparing method thereof

The present invention provides a curing agent that is used for the solid-waste concrete, which comprises 10 to 20 percent of organic compound by weight, and 80 to 90 percent of the inorganic compound by weight, wherein, the organic compound consists of 10 to 20 percent polycyclic aromatic sulfonate and 80 to 90 percent soluble resin sulfonic acid; the inorganic compound consists of 10 percent of industrial salt by weight, 15 percent of potassium chlorate by weight, 10 percent of ammonium chloride by weight, 10 to 15 percent of magnesium chloride by weight, 10 percent of potassium carbonate by weight, 10 percent of sodium carbonate by wt, 5 to 20 percent of magesium cell fluosilicate by wt, and 10 to 25 percent of procoagulant by wt. The present invention also provides a method for producing the curing agent. The present invention can improve the mechanical properties of the solid waste concrete product.

Owner:S_QBEE SHISHI ENVIRONMENTAL PROTECTIVE BUILDINGMATERIALS

Ceramic composite nanofiltration membrane for dye removal and preparation method thereof

ActiveCN111672339AImprove performanceImprove interception effectSemi-permeable membranesGeneral water supply conservationPolymer scienceCeramic composite

The invention relates to a preparation method of a ceramic composite nanofiltration membrane for dye removal, and belongs to the field of membrane separation. A tubular or flaky ceramic substrate is used as a carrier, a dopamine compound and polyethyleneimine form a co-deposition layer on the surface of the carrier, TiO2 is loaded on the co-deposition layer, and finally, gallic acid is used for crosslinking to obtain the composite nanofiltration membrane. The preparation process is simple, the reaction conditions are mild, and the prepared ceramic composite nanofiltration membrane is high in mechanical strength, good in stability, large in permeation flux and high in rejection rate, is suitable for removal of dyes in wastewater and is also suitable for removal of dyes in organic solvents.

Owner:CHONGQING UNIV OF TECH

Anticorrosive protective layer for chemical equipment

InactiveCN104263236AGood paintabilityImprove wettabilityAnti-corrosive paintsPolyether coatingsBenzoic acidPolyethylene glycol

The invention discloses an anticorrosive protective layer for chemical equipment, which is composed of the following components in percentage by weight: 1-2 parts of polyethyleneglycol bis stearate, 2-3 parts of polydimethylsiloxane, 1-2 parts of yttrium oxide, 1-2 parts of sodium pyrophosphate, 1-2 parts of selenium acetylacetonate, 4-5 parts of chromium chloride, 1-2 parts of nano magnesium hydroxide, 2-5 parts of ammonium molybdate, 3-7 parts of perchloroethylene, 7-8 parts of decabromodiphenyl oxide, 2-3 parts of polyamide resin, 1-2 parts of p-tert-butyl benzoic acid, 1-2 parts of vinyl trimethoxy silane, 1-2 parts of allyl heptanoate and 5-6 parts of isomerized tridecyl alcohol polyethenoxy ether. The anticorrosive protective layer has the advantages of favorable brushing property, favorable wettability for object surfaces, high drying speed of the paint film, favorable mechanical property, favorable acid / alkali resistance, favorable water resistance and favorable organic solvent resistance.

Owner:常熟市联明化工设备有限公司

Retanning agent for improving tearing strength of leather and preparation method of retanning agent

InactiveCN108219162AHigh tear strengthImprove antibacterial propertiesTanning treatmentHydrogenHydrogen atom

The invention relates to a retanning agent for improving tearing strength of leather and a preparation method of the retanning agent. The retanning agent is prepared from 2,3-glycidyl ethyl methyl ethylamine chloride grafted gelatin polymer; preparation raw materials of the polymer comprise 2,3-glycidyl ethyl methyl ethylamine chloride and gelatin; for the polymer obtained by addition reaction ofepoxy group of the 2,3-glycidyl ethyl methyl ethylamine chloride and hydrogen atoms of primary amine on gelatin molecules, the breaking elongation is 19mm and the strength is 0.25 to 0.40MPa; the glass transition temperature is 190 to 218 DEG C, the antibacterial rate is 40 to 90 percent, the adsorption dye rate is 60 to 78 percent and the thickening rate is 110 to180 percent. The retanning agentcan significantly improve the tearing strength of the leather, and has the advantages of antibacterial property, adsorption and fixing of dye, bright coating colors and the like.

Owner:QILU UNIV OF TECH

Colorized transparent anti-counterfeit watermark paper and manufacturing method thereof

ActiveCN102191729AGood light fastnessImprove acid resistanceSpecial paperPaper/cardboardOrganic solventPolyvinyl acetate

The invention relates to colorized transparent anti-counterfeit watermark paper and a manufacturing method thereof. The colorized transparent anti-counterfeit watermark paper comprises body paper; a colorized thin film is arranged in the body paper; the using amount of the colorized thin film is 0.1 to 10 percent of the area of the paper; and the colorized thin film is colorized polyvinyl acetate (PVA) or a gelatin thin film, and comprises 0.01 to 0.3weight percent of water-soluble dye. The colorized thin film is processed into a desired shape as required; the colorized thin film is added into paper pulp through an orientated releasing device so that the colorized thin film is directionally distributed on a certain part of the paper or uniformly distributed in the paper. The colorized transparent anti-counterfeit watermark paper manufactured by the method has high light resistance, acid resistance, alkali resistance, oxidant resistance, reductant resistance, organic solvent resistance, heat resistance and the like, so the material can be well applicable to anti-counterfeit and encrypting technical field of securities, tickets, currency paper and the like.

Owner:BAODING BANKNOTE PAPER CO LTD +1

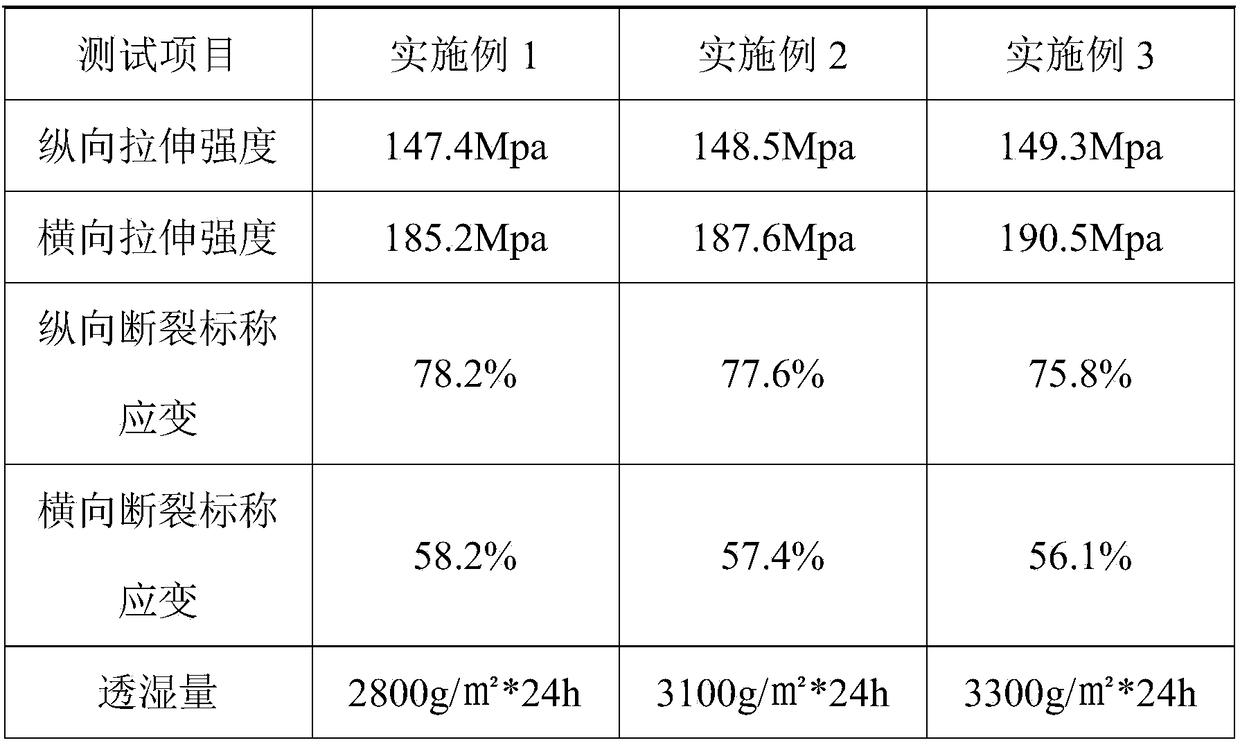

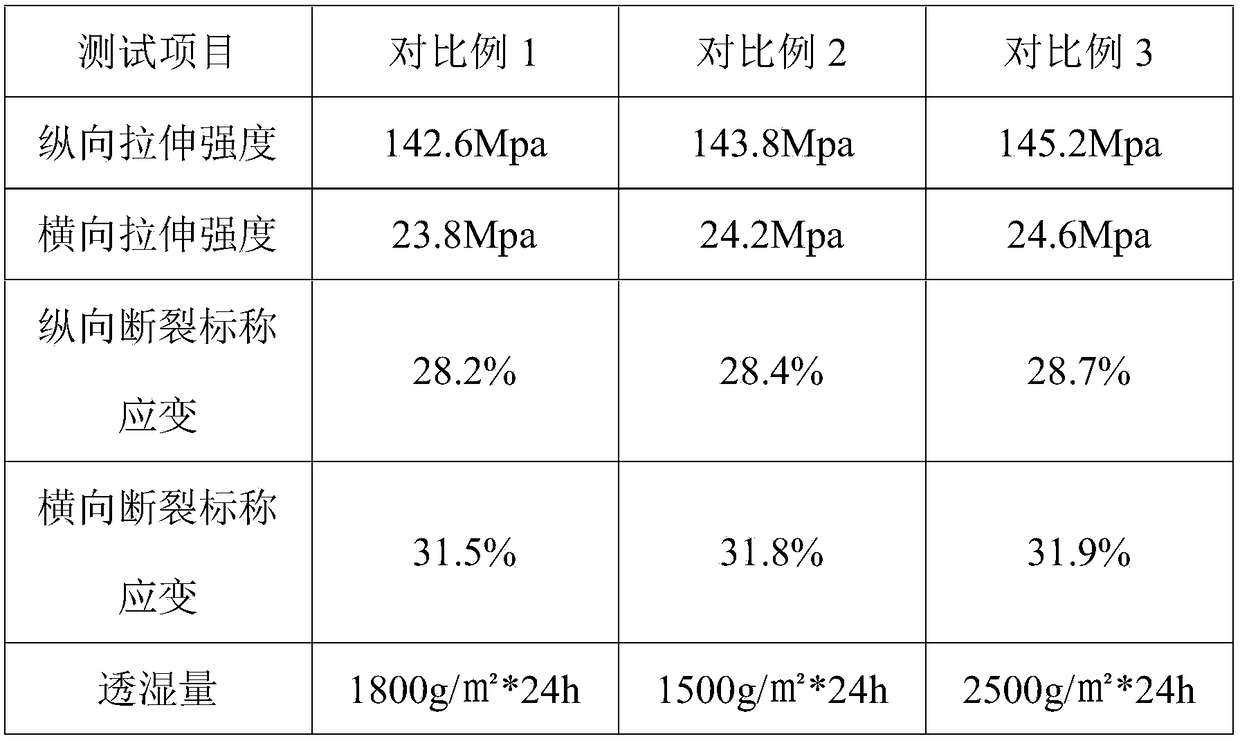

Biaxially oriented polypropylene waterproof breathable film and preparation method thereof

InactiveCN109294056AEasy to shapeImprove mechanical propertiesFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a biaxially oriented polypropylene waterproof breathable film and a preparation method thereof. The waterproof breathable film is composed of the following components in partsby weight: 30-32 parts of homo-polypropylene resin, 50-52 parts of heavy calcium carbonate powder, 1-2 parts of a coupling agent, 5-10 parts of linear low-density polyethylene resin and 6-12 parts oflow-density polyethylene. The biaxially oriented polypropylene waterproof and breathable film prepared according to the formula and the method disclosed by the invention is more excellent in mechanical property and better in toughness, has more uniform and stable longitudinal and transverse properties, has moisture permeability obviously superior to moisture permeability of a similar product prepared by a tape casting method, can be applied to medical sanitary product packaging, food packaging, daily-use products and the like, and has a wide application prospect.

Owner:ANHUI GUOFENG PLASTIC

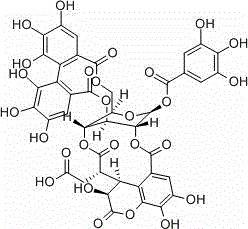

Preparation method of chebulagic acid

InactiveCN104945447AHigh extraction rateHas acid and alkali resistanceEsterified saccharide compoundsSugar derivativesFreeze-dryingHigh selectivity

The invention discloses a preparation method of chebulagic acid, particularly a method for extracting chebulagic acid by ultrasonic-extraction-assisted bioenzyme enzymolysis. The method comprises the following steps: raw material treatment, enzymolysis, ultrasonic extraction, purification, vacuum concentration and freeze-drying to obtain the chebulagic acid. The method has the advantages of simple technique, mild reaction conditions, high selectivity, high chebulagic acid purity and the like.

Owner:NANJING ZELANG MEDICAL TECH

Making process and product of color vacuum aluminium plating paper as package material

InactiveCN1184378CImprove the finishGood resistance to organic solventsFlexible coversWrappersPolyesterPolymer science

In the present invention, polyester film is painted with easy-to-peel coating, sprayed with aluminium and adhered with paper layer, and the polyester film is then peeled and paint containing pigment is painted to the easy-to-peel coating to obtain the product. The easy-to-peel coating consists of nitro cellulose and acrylic resin. The improved easy-to-peel coating has raised organic solvent resistance, can be colored in great area, and is covered with rougher easy-to-peel layer and thus has high smoothness and mirror effect. The aluminum-plating paper can be printed and colored in controlled color difference.

Owner:汕头市绿新企业咨询有限公司

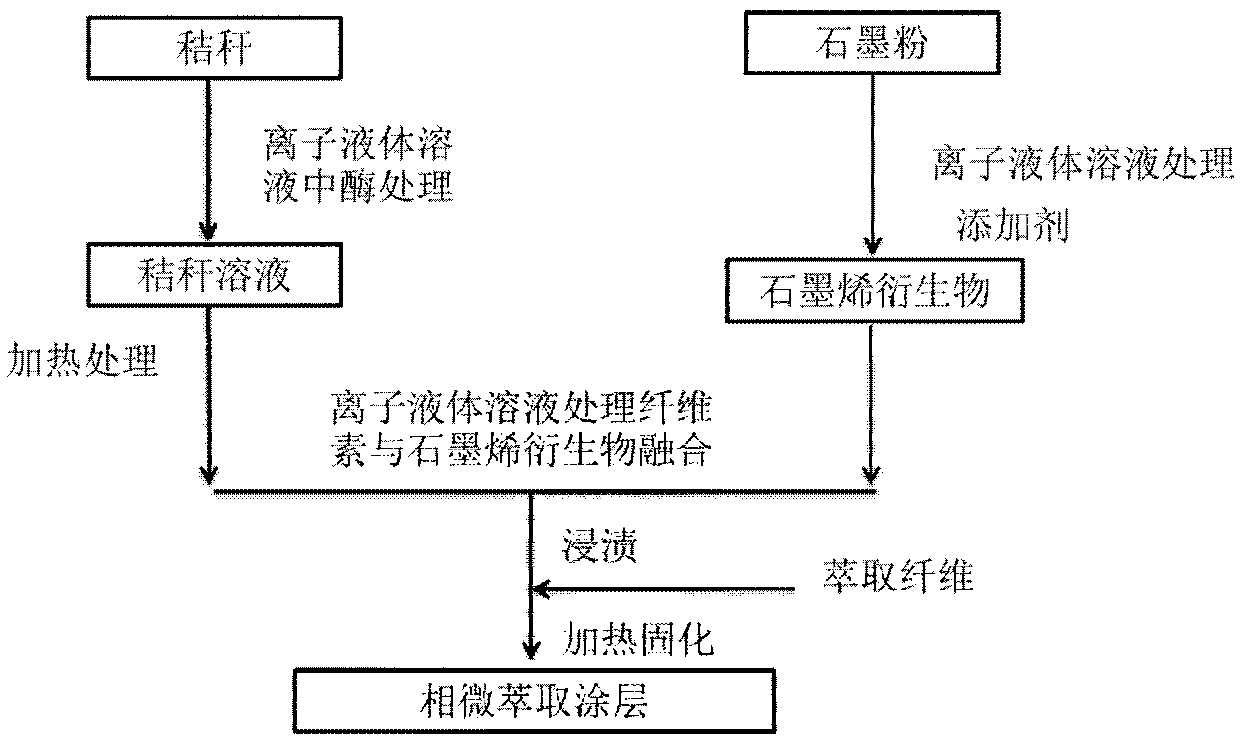

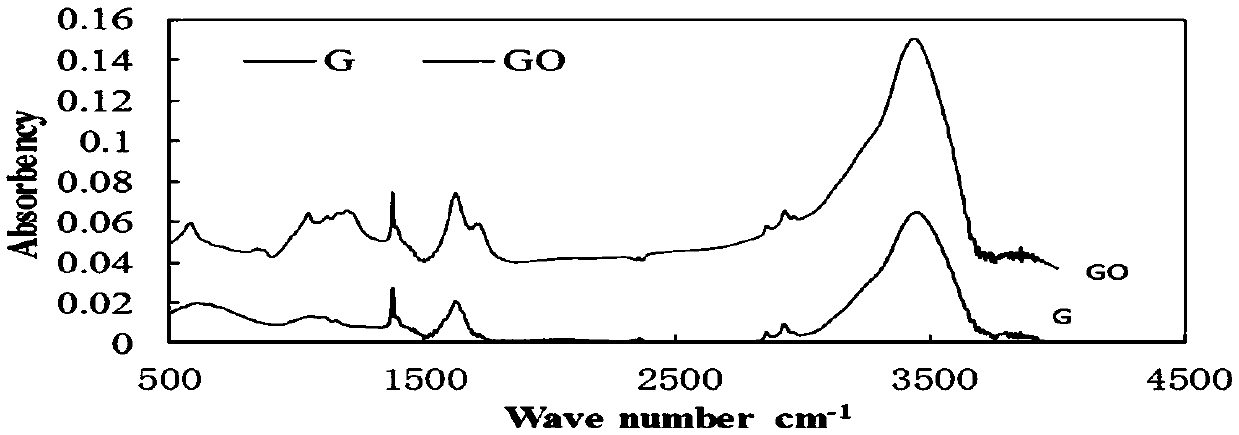

Preparation method of solid phase microextraction coating

ActiveCN109596398AReduce pollutionHigh mechanical strengthPreparing sample for investigationFiberSolid-phase microextraction

The invention discloses a preparation method of a solid phase microextraction coating. The method comprises the following steps: adding straws and biological enzymes into an ionic liquid water solution; adding a mixed solution of an acidic ionic liquid and DMSO (dimethyl sulfoxide) after completing the reaction; performing heating to obtain a straw solution; adding graphite powders into the ionicliquid; performing ultrasonic preprocessing; adding sulfuric acid and potassium permanganate; performing ultrasonic preprocessing once again; imforming oxygen; performing centrifuging, washing, precipitating and drying to obtain graphene oxide; adding the graphene oxide into the acidic ionic liquid; adding 1-methylimidazole, n-methylpyridine or pyrrolidone; performing heating to obtain a grapheneoxide derivative; mixing the straw solution and the graphene oxide derivative; performing heating to obtain a sol solution; taking extraction fibers to form a rough surface; washing with an organic solvent; performing ultrasonic and drying; immersing in the sol solution; immersing in a polar solvent; and performing drying. The method has the advantages of being good in biocompatibility, high in enrichment capacity, stable in extraction coating, long in service life and the like.

Owner:JIANGSU UNIV OF SCI & TECH

Abrasion-resistant metal pipeline with internal anti-corrosion coating

InactiveCN103540862AAchieve resistance reductionEvenly distributedFurnace typesAnti-corrosive paintsHardnessSolid solution strengthening

The invention relates to an abrasion-resistant metal pipeline with an internal anti-corrosion coating. An abrasion-resistant pipeline body is manufactured through centrifugal casting, and is also subjected to quenching, high-temperature tempering, solid solution strengthening thermal treatment as well as twice tempering dispersion hardening thermal treatment technology, and finally, an anti-corrosion coating is coated on the inner wall of the pipeline through air spraying. The metal pipeline has high hardness and abrasion-resistant performance; the anti-corrosion coating has excellent waterproofness, antifouling effect as well as high-temperature-resistant performance.

Owner:徐梁冰

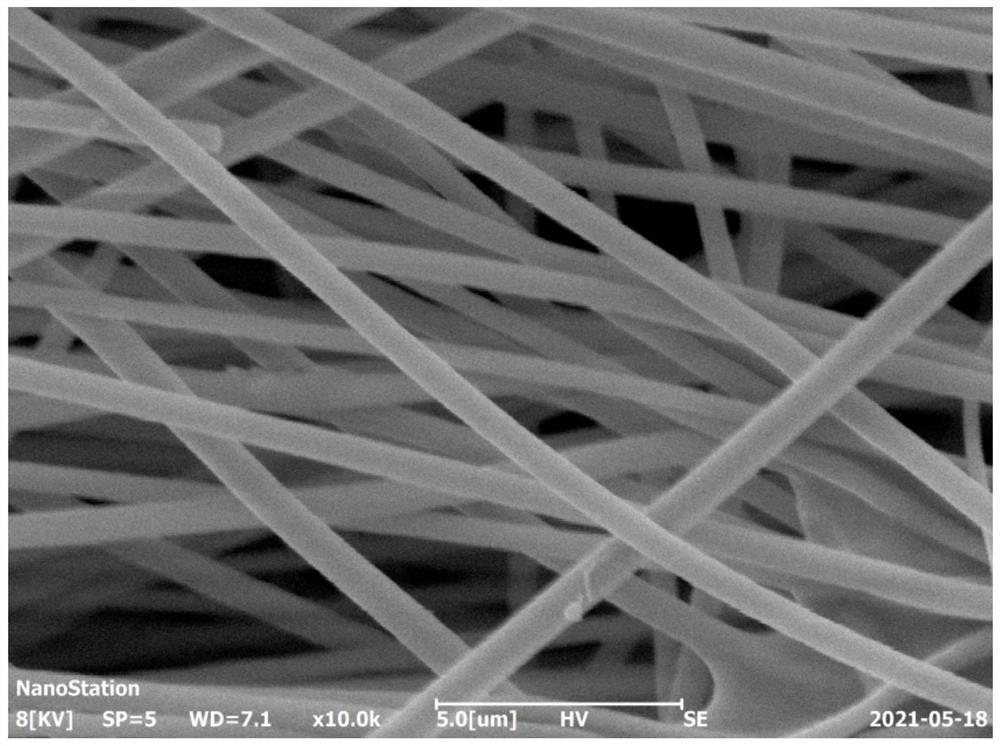

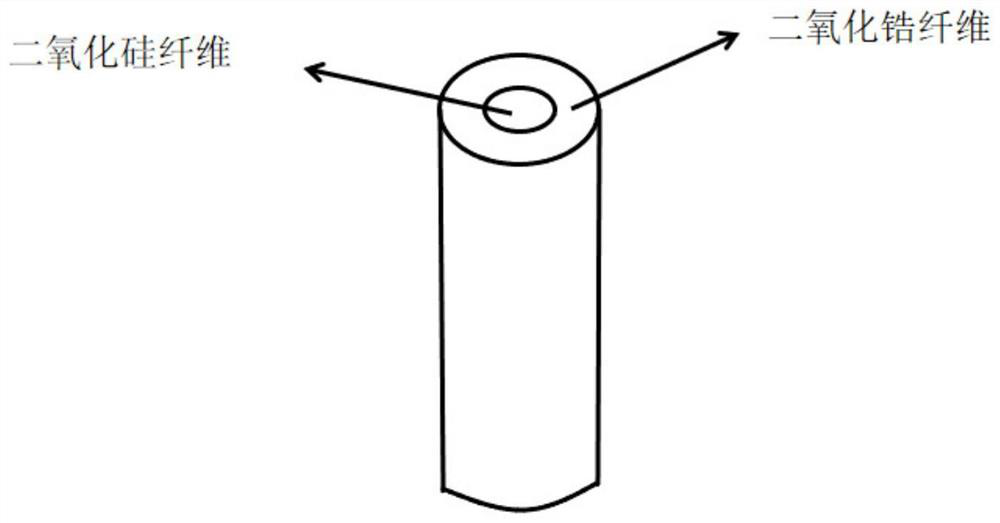

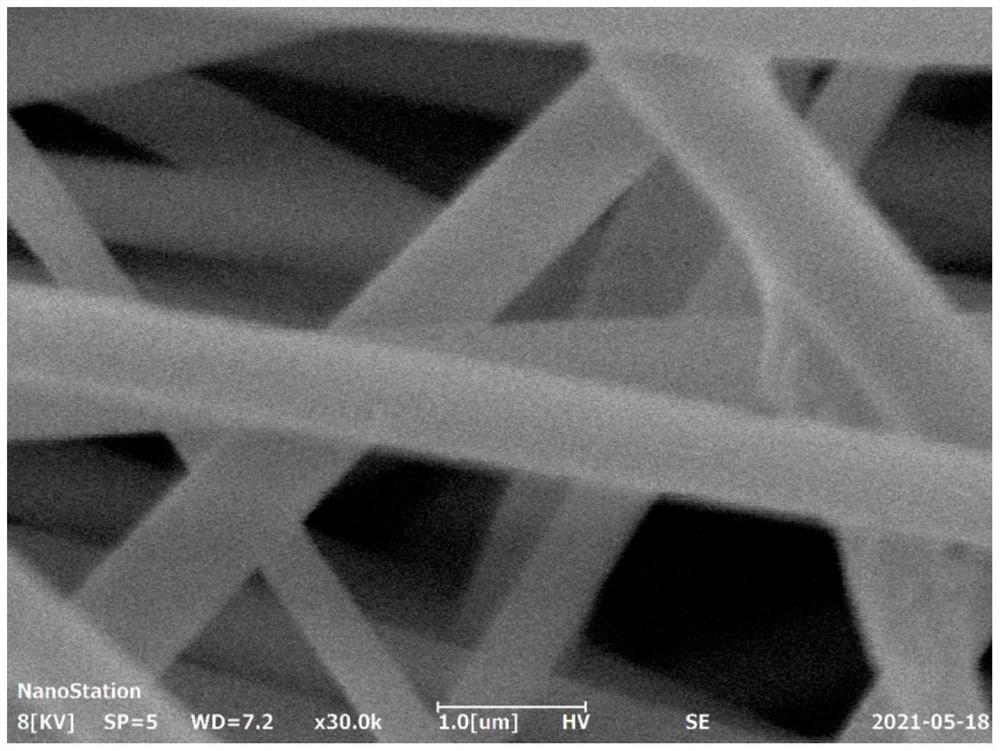

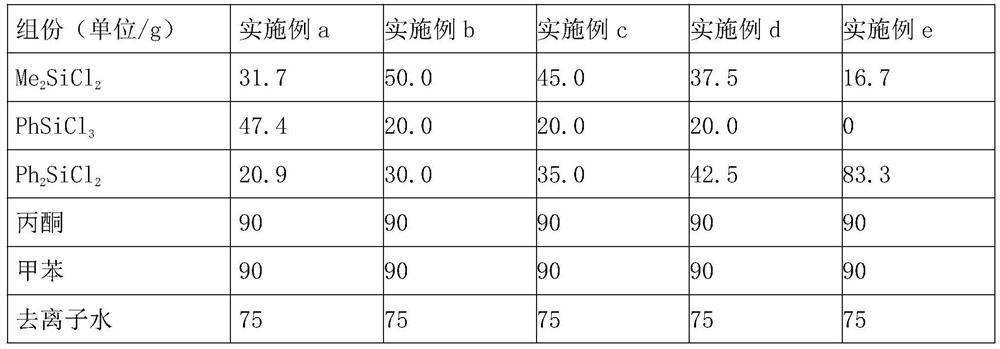

Preparation method of flexible composite nanofiber membrane with core-shell structure

PendingCN113981618ACut end effectImprove high temperature resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsSpinningZirconium oxychloride

The invention discloses a preparation method of a flexible composite nanofiber membrane with a core-shell structure, the preparation method comprises the following steps: mixing tetraethoxysilane, pure water, absolute ethyl alcohol and anhydrous acetic acid, and stirring until the mixture is clear to prepare a silicon source solution; dissolving a high-molecular polymer in a solvent to prepare a high-molecular polymer solution; preparing an absolute ethyl alcohol solution of zirconium oxychloride, adding anhydrous acetic acid, and stirring at normal temperature until the solution is clear to prepare a zirconium source solution; mixing and stirring the prepared silicon source solution and the prepared high-molecular polymer solution in a water bath, mixing and stirring the prepared zirconium source solution and the prepared high-molecular polymer solution in a water bath, and respectively standing and aging to prepare a silicon source spinning solution and a zirconium source spinning solution; carrying out coaxial electrostatic spinning by taking the silicon source spinning solution as a core spinning solution and the zirconium source spinning solution as a shell spinning solution to prepare a flexible composite nanofiber membrane precursor with a core-shell structure; and sintering the flexible composite nanofiber membrane precursor with the core-shell structure to prepare the flexible composite nanofiber membrane with the core-shell structure.

Owner:佛山(华南)新材料研究院 +1

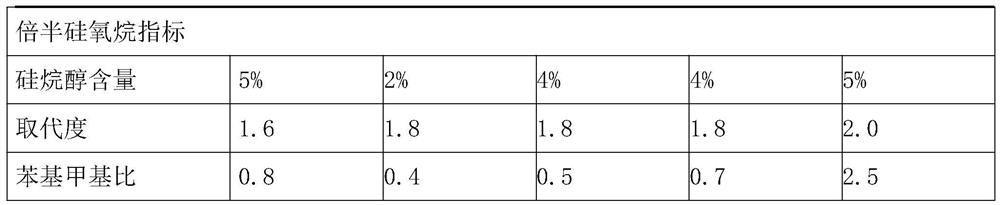

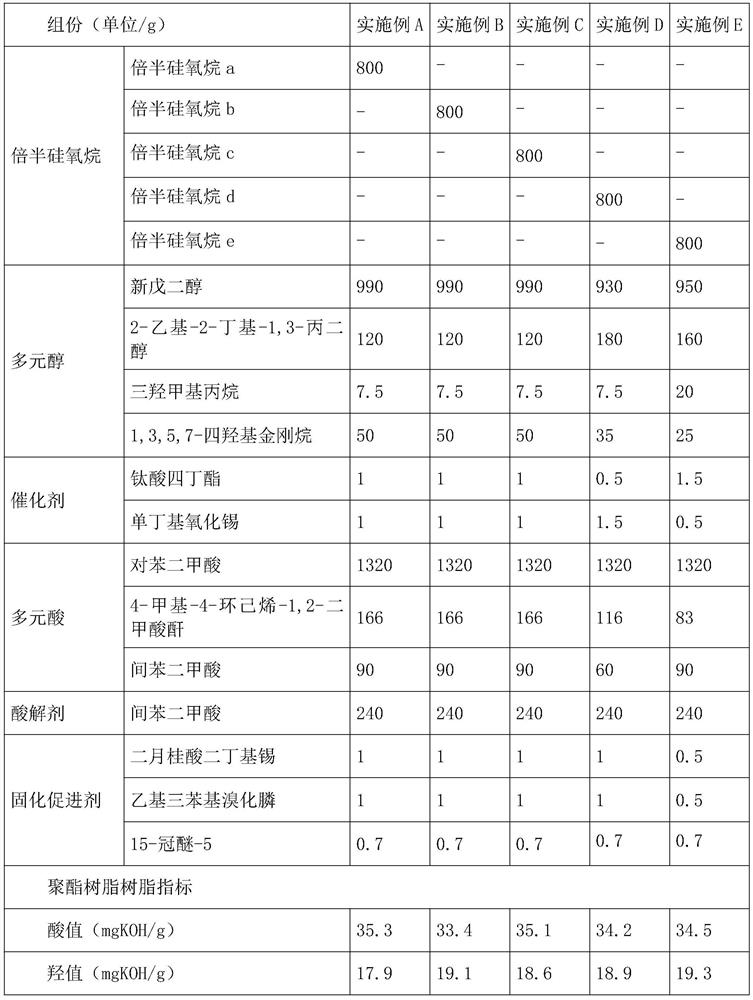

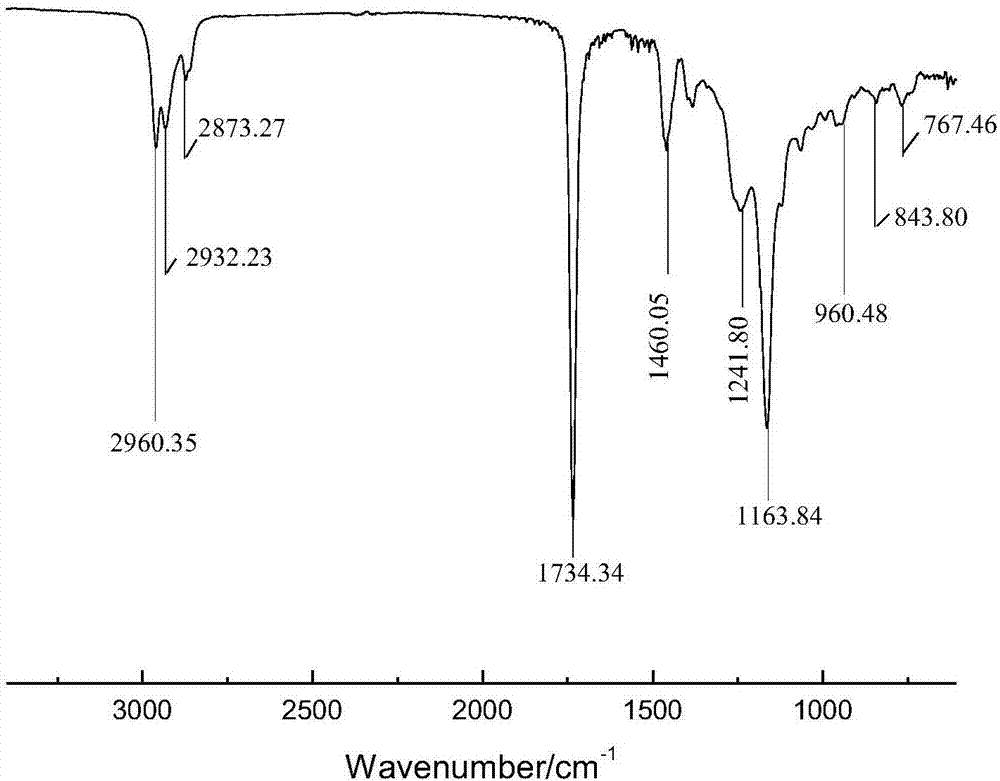

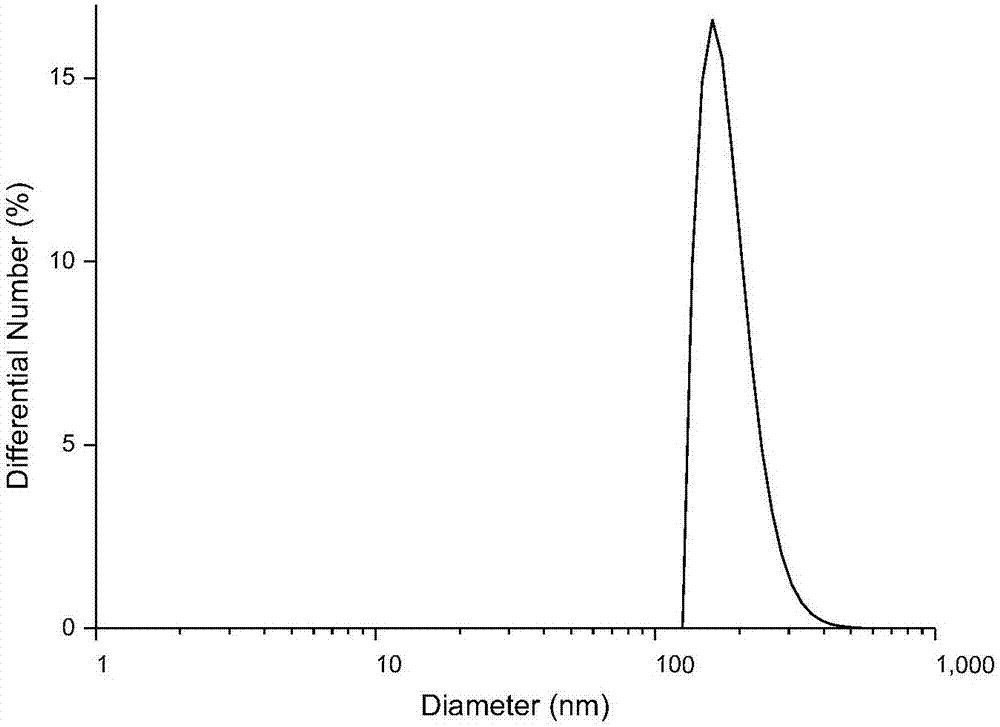

Silsesquioxane modified bifunctional polyester resin and preparation method thereof

ActiveCN111995743AHigh grafting rateGood mattingFireproof paintsPowdery paintsPolymer sciencePtru catalyst

The invention relates to silsesquioxane modified bifunctional polyester resin and a preparation method thereof. The invention discloses a silsesquioxane modified bifunctional polyester resin, which isobtained by melt phase polycondensation of the following raw materials (by weight): 20.0 to 55.0 percent of silsesquioxane, 25.0 to 40.0 percent of polyhydric alcohol, 25.0 to 50.0 percent of polyatomic acid, 4.0 to 18.0 percent of an acidolysis agent, 0.03 to 0.12 percent of a catalyst and 0.01 to 0.4 percent of a curing accelerator; the acid value of the silsesquioxane modified bifunctional polyester resin is 30.0 to 36.0 mg KOH / g; the hydroxyl value is 12.0 mgKOH / g to 22.0 mgKOH / g, the glass transition temperature is 66.0 DEG C to 76.0 DEG C, the rotary viscosity is 8,000 mPa.s / 200 DEG C to 18,000 mPa.s / 200 DEG C, and the number-average molecular weight is 8,000 to 18,000. The silsesquioxane modified bifunctional polyester resin for the high-temperature-resistant powder coating provided by the invention has dual properties of inorganic and organic compounds, and has the technical characteristics of good extinction property, good high-temperature resistance, good organic solvent resistance, good mechanical property and good adhesive force.

Owner:ZHEJIANG CHUANHUA TIANSONG NEW MATERIAL CO LTD

Polyacrylate emulsion adhesive and preparation method thereof

ActiveCN106939062AGood alkali resistanceImprove stabilityNon-macromolecular adhesive additivesGraft polymer adhesivesAdhesiveMonomer

The invention provides a polyacrylate emulsion adhesive. The polyacrylate emulsion adhesive is prepared from 100 parts by weight of a polymerized monomer, 0.1 to 0.3 parts by weight of a polymerization regulator, 140 to 160 parts by weight of water, 0.37 to 0.75 parts by weight of a reactive emulsifier, 0.37 to 0.75 parts by weight of a nonionic emulsifier, 0.3 to 0.8 parts by weight of an initiator, 1 to 5 parts by weight of gamma-glycidoxypropyltrimethoxysilane and 0.5 to 1 part by weight of a stabilizer. The reactive emulsifier is ammonium 1-allyloxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ether sulfate. The nonionic emulsifier is an APEO-containing nonionic emulsifier. Through synergism of the gamma-glycidoxypropyltrimethoxysilane, reactive emulsifier and nonionic emulsifier, the polyacrylate emulsion has high stability. The emulsion particles have uniform sizes, regular shapes, good alkali resistance, organic solvent resistance and water resistance.

Owner:GUANGDONG UNIV OF TECH

Method for preparing polyamide composite nanofiltration membrane based on green and environment-friendly ionic liquid

InactiveCN112934005AExcellent resistance to organic solventsImprove pressure resistanceReverse osmosisCongo redVitamin B12

The invention discloses a method for preparing a polyamide composite nanofiltration membrane based on a green and environment-friendly ionic liquid, which comprises the following steps: dissolving a polymer (poly (m-phenylene isophthalamide)) by using the green and environment-friendly ionic liquid (1-ethyl-3-methylimidazole acetate) to prepare a porous base membrane; and using another green and environment-friendly ionic liquid (1-butyl-3-methylimidazole bis (trifluoromethanesulfonyl) imide salt) as an oil phase for interfacial polymerization on the surface of the base membrane to prepare a polyamide selection layer under the condition that both the ionic liquid phase and the water phase adopt mixed monomers, so that the polyamide composite nanofiltration membrane with high separation performance is obtained. The process is low in cost, safe, green and environment-friendly. The polyamide composite nanofiltration membrane prepared by the process has an excellent separation effect on organic solutions containing Congo red, acid red 94, solvent red, brilliant blue R, amaranth red, rhodamine B, vitamin B12 and other dyes (or drugs).

Owner:HUAQIAO UNIVERSITY

Extraction method for antibacterial peptide

PendingCN112521444AApplicableInhibit treatment conditionsAntibacterial agentsCosmetic preparationsDisulfide bondingPropanoic acid

The invention provides an extraction method for an antibacterial peptide. The antibacterial peptide is obtained through mixing a variety of botanical raw materials and carrying out extracting. The obtained antibacterial peptide has spectral applicability, the molecular weight of overall active regions is smaller than 5kDa, and the antibacterial peptide has a stable disulfide bond structure and isgood in acid resistance, organic solvent resistance and thermal stability; the extraction method is simple in operation, the production efficiency is increased, the production cost is reduced, and thus, the extraction method is in line with industrial production; and the extracted antibacterial peptide has a remarkable inhibiting action on propionibacterium acnes, can be effectively applied to anti-acne products and exerts excellent bacteriostatic, inflammation diminishing and calming effects. Furthermore, the extraction method employs an online control system, treatment conditions of a treatment still can be more accurately controlled, the impurity ingredients are few, and thus, the quality of extracting is guaranteed.

Owner:广东鑫皇冠新材料有限公司

Novel logistics vehicle

InactiveCN104277535AGood acid and alkali resistanceImprove water resistanceAnti-corrosive paintsHand carts with one axisDecabromodiphenyl etherCarboxylic acid

The invention discloses a novel logistics vehicle which comprises a baseplate, a goods shelf is fixed on the baseplate, and the bottom of the baseplate is provided with a roller; the goods shelf is made of an alloy material, the alloy material is coated with an anti-corrosion coating, and the anti-corrosion coating is composed of the following components in parts by weight: 2-3 parts of hydroxy propyl methylcellulose, 2-3 parts of allyl heptanoate, 3-4 parts of perchloroethylene, 8-9 parts of tetrabutylammonium bromide, 6-7 parts of a triazine polycarboxylic compound, 1-2 parts of decabromodiphenyl ether, 5-6 parts of selenium acetylacetonate, 2-3 parts of chromium chloride, 1-2 parts of polyamide resin, 1-2 parts of yttrium oxide, and 4-5 parts of isomeric alcohol ethoxylates. The position of the goods shelf of the logistics vehicle disclosed by the invention is coated with the anti-corrosion coating, and therefore, the logistics vehicle is good in acid and alkali resistance, water resistance and organic solvent resistance.

Owner:CHANGSHU YIRUNDA BUSINESS EQUIP FACTORY

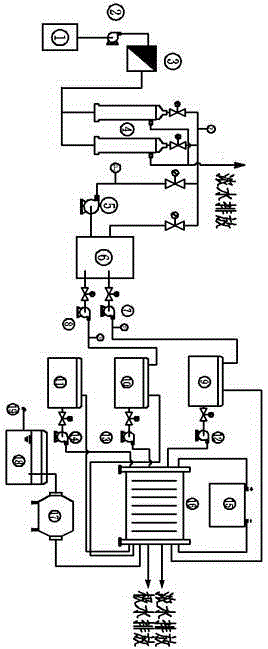

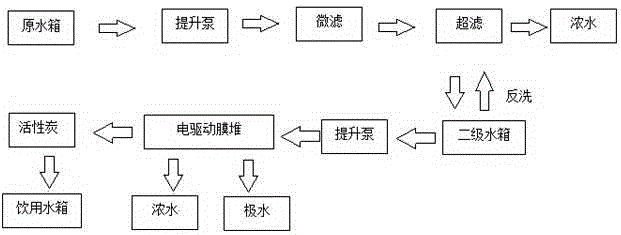

Multi-membrane-method sea water desalination integrated device

InactiveCN105174545AIncrease water fluxHigh breaking strengthSeawater treatmentMultistage water/sewage treatmentWater desalinationWater quality

The invention provides a multi-membrane-method sea water desalination integrated device. According to the multi-membrane-method sea water desalination integrated device, a novel multi-membrane-method sea water desalination integrated technology is created by coupling microfiltration, ultrafiltration, frequent electrodialysis reversal and active carbon optimizing, and aims at solving the problems of membrane pollution and the like in the sea water desalination process; an ultrafiltration membrane with high pollution resistance is adopted for a pre-treatment system, and the ultrafiltration membrane and an electric-driving homogeneous membrane form a double-membrane system, so that the system is more stable in running, the service life of the system is prolonged, and it is guaranteed that the quality of yielded water meets a tap water standard; the sea water desalination integrated technology is a novel sea water desalination technology.

Owner:江苏省科建成套设备有限公司

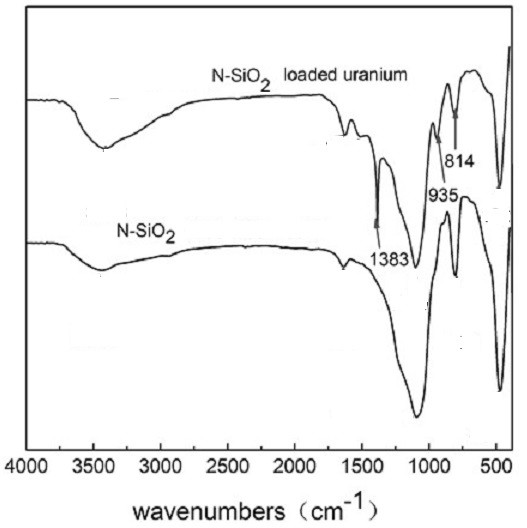

Uranium separation material and preparation method thereof

ActiveCN112403439AImprove adsorption capacityFast dynamicsOther chemical processesProcess efficiency improvementPhosphonium saltOrganic solvent

The invention discloses a material for separating uranium from alkaline nuclear industry low-level radioactive wastewater and seawater and a preparation method of the material. The material for separating uranium is quaternary ammonium salt or quaternary phosphonium salt grafted silicon dioxide. The material can form stable covalent bonds with organic functional groups; the balance time is moderate, and the balance of surface activation can be achieved within multiple hours; the material is a high-specific-surface-area matrix material and is low in cost; silicon has a high-quality exchange characteristic and does not expand; and the material has the advantages of good organic solvent resistance and very high thermal resistance.

Owner:LANZHOU UNIVERSITY

Novel method for preparing ion exchange fiber by graft copolymerization

ActiveCN100439591CRaw materials are easy to getSimple preparation processFibre treatmentAnion exchangersResource recoveryIon exchange

The present invention relates to co-irradiation grafting modification and functional reaction process of preparing ion exchange fiber on the basis of synthetic fiber. The co-irradiation grafting copolymerization reaction process is controlled in homopolymer production to raise grafting efficiency, and has proper cross-linking agent is added to raise the mechanical performance of the fiber, and the ion exchange fiber passing through the functional reactions has relatively high exchange capacity. The ion exchange fiber the present invention prepared has great exchange capacity, fast exchange speed, short regeneration time, high stability, simple production process, low cost and other advantages, and may be used widely in environment protection, food decolorizing, wet metallurgy, water treatment, resource recovering and other fields.

Owner:桂林正翰科技开发有限责任公司

Preparation method for anti-corrosion mechanical coating

InactiveCN106519763AImprove wettabilityImprove mechanical propertiesAnti-corrosive paintsSodium acetateMechanical property

The invention relates to an anti-corrosion mechanical coating and a preparation method thereof. The anti-corrosion mechanical coating is made from the following components in parts by weight: 6-10 parts of allyl heptylate, 8-12 parts of acetyl acetone selenium, 3-6 parts of polyamide resin, 5-11 parts of sodium acetate, 1-3 parts of glass fiber, 2-4 parts of sodium oxalate, 6-10 parts of fluorine-containing rusty emulsion, 3-5 parts of xylene and 15-20 parts of deionized water. The anti-corrosion mechanical coating has the beneficial effects of being convenient to use, easy to produce and manufacture, good in brushability and object surface wettability, rapid in paint film drying and good in mechanical property, acid and alkali resistance, water resistance and organic solvent resistance.

Owner:邓集叶

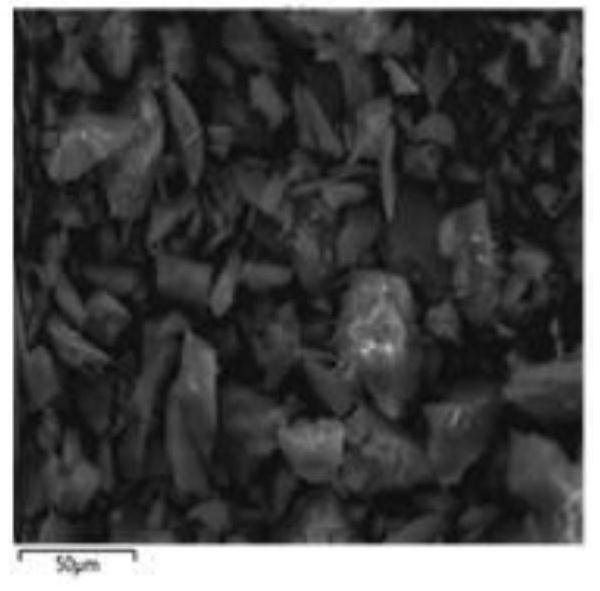

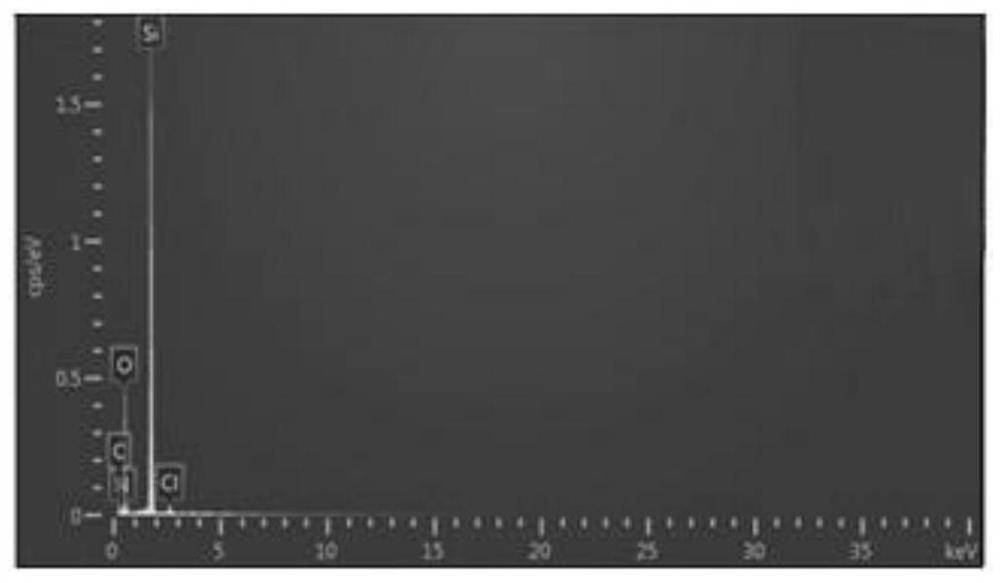

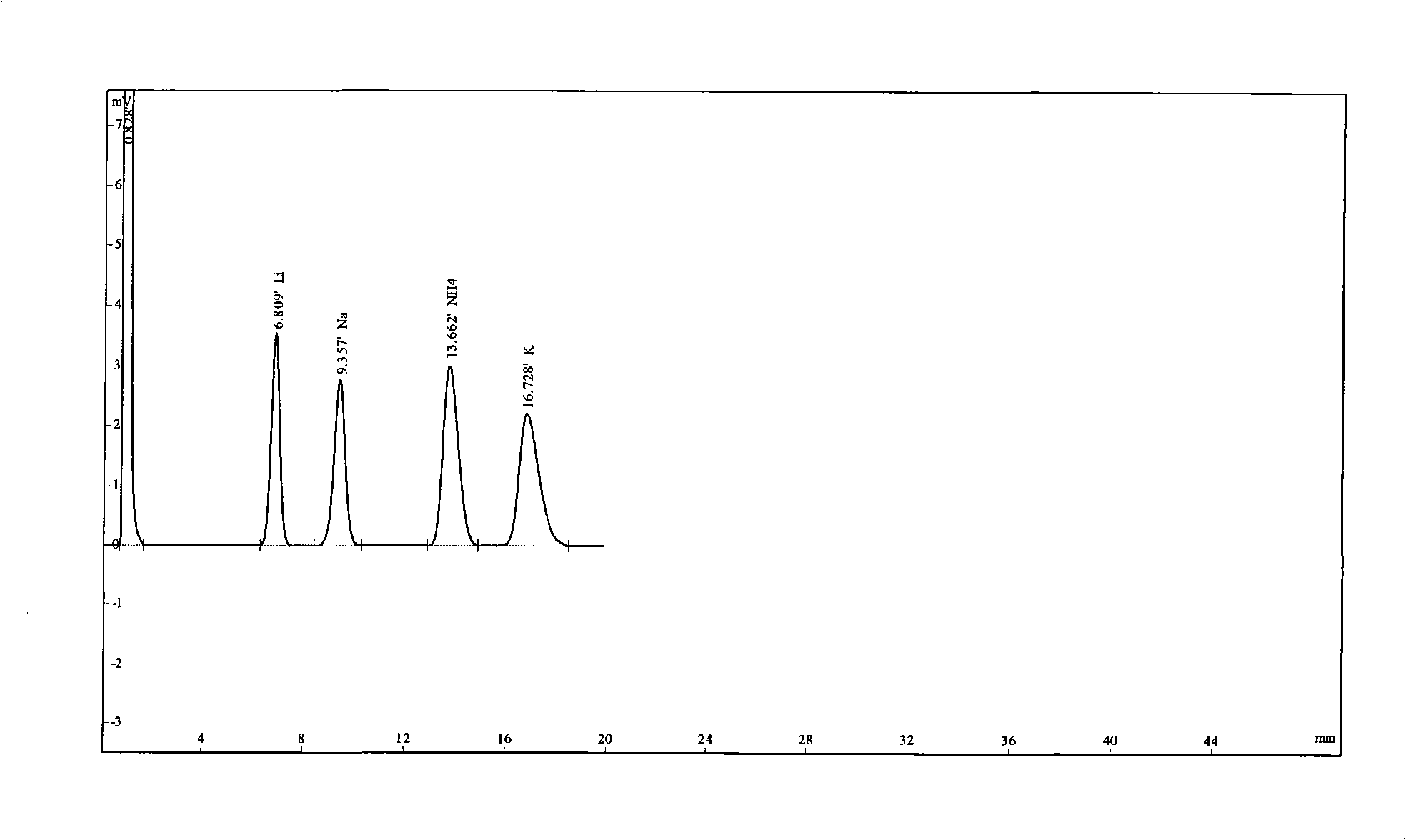

Synthetic method of superficially pellicular packing stuffing for strong-acid cation chromatographic column and product

InactiveCN101406852AHigh strengthHigh strength of aromatic olefin organic matrix resinChromatographic cation exchangersOrganic solventSynthesis methods

The invention provides a method for synthesizing fillers for a surface-pellicular highly-acidic cationic chromatographic column. The method comprises the following steps: synthetic shape-crosslinking aromatic olefin organic matrix resin is sulphonated and then packed into a column, and the synthetic shape-crosslinking aromatic olefin organic matrix resin reacts with concentrated sulphuric acid or chlorosulfonic acid at a temperature between 5 and 40 DEG C, so as to perform sulfonation treatment. The synthetic shape-crosslinking aromatic olefin organic matrix resin is subjected to the sulfonation treatment under the condition of low temperature, thereby ensuring that the sulfonation degree is low and the resin can not be damaged when the reaction is stopped. The aromatic olefin organic matrix resin with high synthetic shape-crosslinking degree is high in strength and strong in the performance of tolerating organic solvents. A resin product produced by the synthesis method has good integrity. When having higher crosslinking degree, the synthetic resin is good in the performance of tolerating the organic solvents.

Owner:QINGDAO SHENGHAN CHROMATOGRAPH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com