Modified epoxy resin adhesive and its preparation process

A technology of epoxy resin and adhesive, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of brittleness and poor temperature resistance, and achieve excellent oil resistance, good alkali resistance and good bonding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

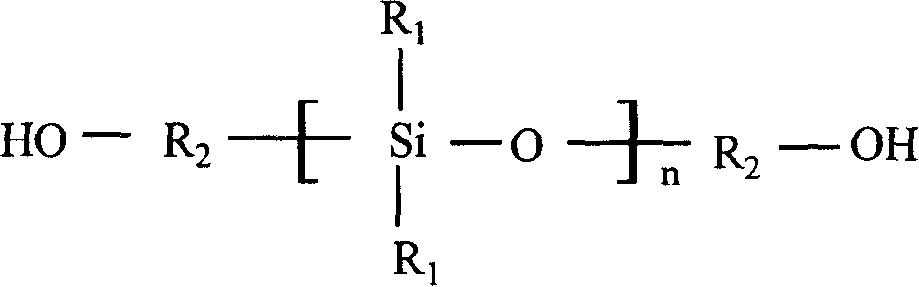

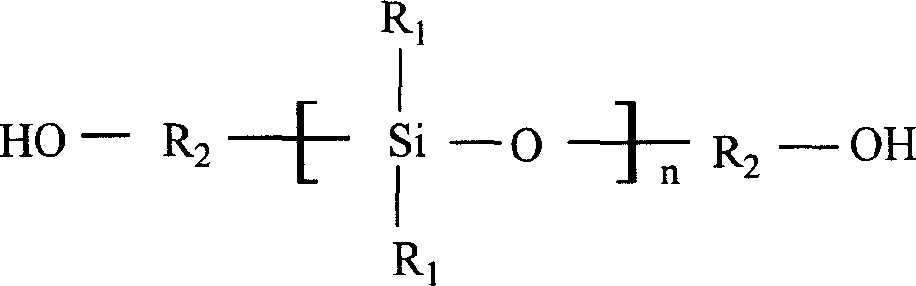

[0024] Preparation of Polysiloxane Polyurethane Prepolymer

[0025] Add 100 g of hydroxyl-terminated polysiloxane resin (Mn=1000) into a three-necked flask with a stirrer and a thermometer, heat to 70-100°C, and vacuum dehydrate for 2 hours, then add 20 g of toluene diisocyanate (TDI), and The polysiloxane polyurethane prepolymer is obtained by reacting at 70-100° C. for 1-3 hours, and the NCO content is 6%.

[0026] Preparation of Modified Epoxy Resin (Component A)

[0027] Put 80g of bisphenol A epoxy resin (R-140) and 20g of polysiloxane polyurethane prepolymer (NCO content is 6%) into the reactor, heat up and stir, and start vacuuming when the temperature rises to 90°C (remaining pressure 10 ~ 30mmHg) and constant temperature reaction for 2 hours.

[0028] Preparation of Curing Agent Components (Part B)

[0029] Add 20g of hexamethylenediamine into the reactor, heat to 100°C, stir and add 8g of 2-methylimidazole, keep 100°C under vacuum for 2 hours, then add 4g of γ-ami...

Embodiment 2

[0032] Preparation of Polysiloxane Polyurethane Prepolymer

[0033]Add 100 g of hydroxyl-terminated polysiloxane resin (Mn=1000) into a three-neck flask with a stirrer and a thermometer, heat to 70-100°C, and vacuum dehydrate for 2 hours, then add 20.3 g of toluene diisocyanate (TDI), The polysiloxane polyurethane prepolymer is obtained by reacting at 70-100 DEG C for 1-3 hours, and the NCO content is 8%.

[0034] Preparation of Modified Epoxy Resin (Component A)

[0035] Add 90g of bisphenol A epoxy resin (R-140) and 10g of polysiloxane polyurethane prepolymer (8% NCO content) into the reactor, heat and stir, and start vacuuming when the temperature rises to 90°C (remaining pressure 10 ~ 30mmHg) and constant temperature reaction for 2 hours.

[0036] Preparation of Curing Agent Components (Part B)

[0037] Add 15g of N,N-diamino-diphenylmethane into the reactor, heat up to 100°C, add 10g of imidazole with stirring, keep 100°C under vacuum for 2 hours, then add γ-aminopropy...

Embodiment 3

[0040] Preparation of Polysiloxane Polyurethane Prepolymer

[0041] Add 100 g of hydroxyl-terminated polysiloxane resin (Mn=1000) into a three-necked flask with a stirrer and a thermometer, heat to 70-100°C, and vacuum dehydrate for 2 hours, then add 19.5 g of toluene diisocyanate (TDI), The polysiloxane polyurethane prepolymer is obtained by reacting at 70-100 DEG C for 1-3 hours, and the NCO content is 4%.

[0042] Preparation of Modified Epoxy Resin (Component A)

[0043] Add 70g of bisphenol A epoxy resin (R-140) and 30g of polysiloxane polyurethane prepolymer (NCO content is 4%) into the reactor, heat up and stir, and start vacuuming when the temperature rises to 90°C (remaining pressure 10 ~ 30mmHg) and constant temperature reaction for 2 hours.

[0044] Preparation of Curing Agent Components (Part B)

[0045] Add 25g of hexamethylenediamine into the reactor, heat up to 100°C, stir and add 4g of 2-methylimidazole, keep it under vacuum at 100°C for 2 hours, then add 6g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com