Solidifying agent used as solid castoff concrete and preparing method thereof

A solid waste and curing agent technology, applied in the field of building materials and environmental protection, can solve the problem of low strength, and achieve the effect of good organic solvent resistance, excellent corrosion resistance and small shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

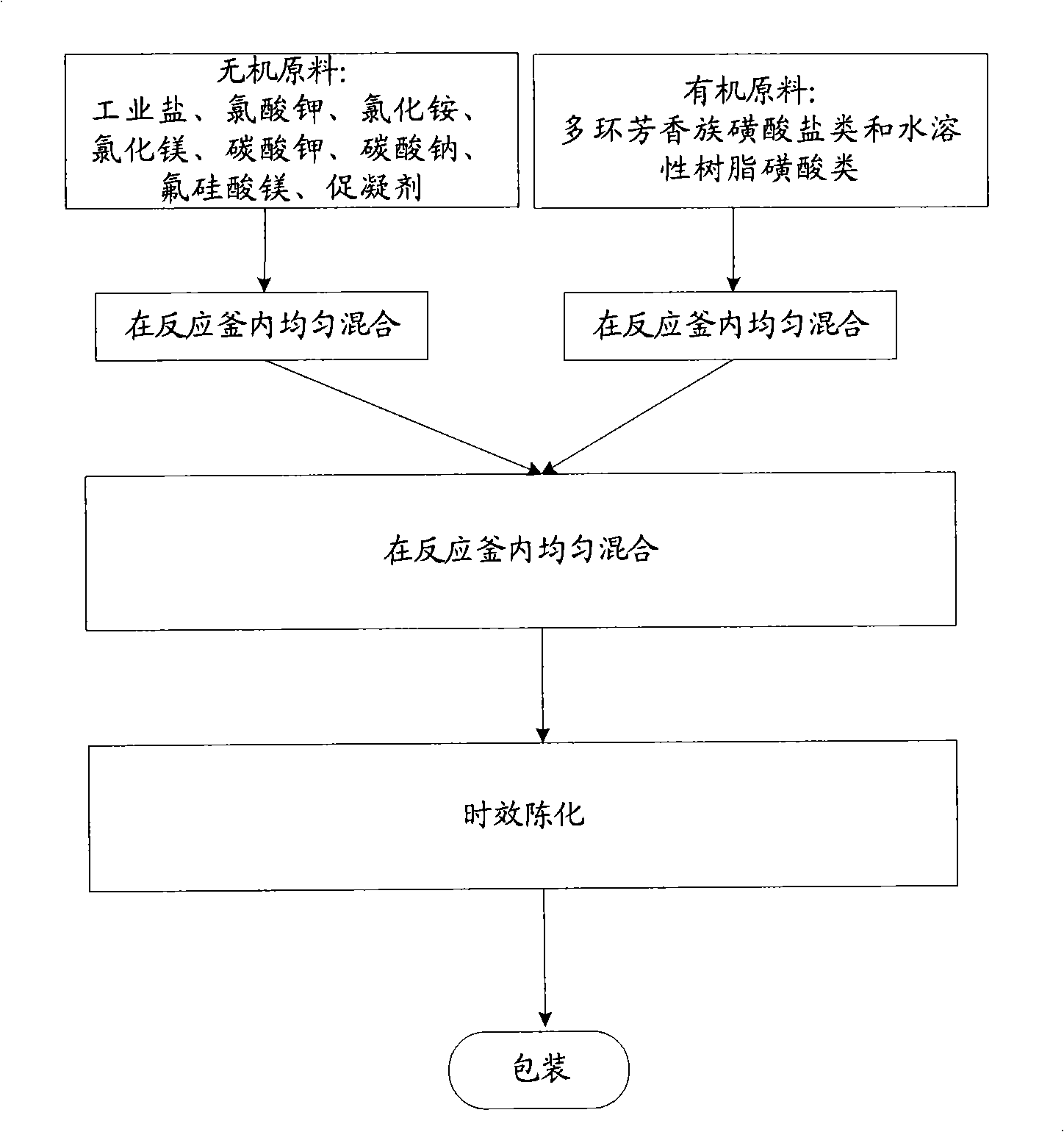

Method used

Image

Examples

Embodiment 1

[0037] 10 wt% of polycyclic aromatic sulfonates and 90 wt% of water-soluble resin sulfonic acids are uniformly mixed in a stirred reactor. constitute organic components. Then 10wt% of industrial salt, 15wt% of potassium chlorate, 10wt% of ammonium chloride, 15wt% of magnesium chloride, 10wt% of potassium carbonate, 10wt% of sodium carbonate, 5wt% of magnesium fluorosilicate, and 25wt% of coagulant were mixed in the stirred reactor Uniform, constitutes an inorganic component. Stir 20wt% of organic components and 80wt% of inorganic components evenly in a stirred reactor to make a curing agent, which can be put into plastic barrels of uniform specifications.

[0038] When using this curing agent to prepare concrete, the following formula (weight percentage) is adopted:

[0039] cement

water

ceramic aggregate

Garbage incineration ash

fine sand

This curing agent

10

4

25

45

8

3

5

...

Embodiment 2

[0043]20 wt% of polycyclic aromatic sulfonates and 80 wt% of water-soluble resin sulfonic acids are uniformly mixed in a stirred reactor. constitute organic components. Then 10wt% industrial salt, 15wt% potassium chlorate, 10wt% ammonium chloride, 10wt% magnesium chloride, 10wt% potassium carbonate, 10wt% sodium carbonate, 10wt% magnesium fluorosilicate, and 25wt% coagulant were mixed in the stirred reactor Uniform, constitutes an inorganic component. Stir 10wt% of the organic component and 90wt% of the inorganic component in a stirred reactor to make a curing agent and put it into a plastic bucket of uniform specifications.

[0044] When using this curing agent to prepare concrete, the following formula (weight percentage) is adopted:

[0045] cement

water

ceramic aggregate

Garbage incineration ash

fine sand

This curing agent

10

4

20

50

8

3

5

[0046] After testing, the main...

Embodiment 3

[0049] 20 wt% of polycyclic aromatic sulfonates and 80 wt% of water-soluble resin sulfonic acids are uniformly mixed in a stirred reactor. constitute organic components. Then 10wt% industrial salt, 15wt% potassium chlorate, 10wt% ammonium chloride, 10wt% magnesium chloride, 10wt% potassium carbonate, 10wt% sodium carbonate, 10wt% magnesium fluorosilicate, and 25wt% coagulant were mixed in the stirred reactor Uniform, constitutes an inorganic component. Stir 20wt% of organic components and 80wt% of inorganic components evenly in a stirred reactor to make a curing agent, which can be put into plastic barrels of uniform specifications.

[0050] When using this curing agent to prepare concrete, the following formula (weight percentage) is adopted:

[0051] cement

water

ceramic aggregate

Garbage incineration ash

fine sand

This curing agent

10

4

15

55

6

5

5

[0052] After testing, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com