An embedded mesh core type metal powder metallurgy process

A technology of powder metallurgy and metal powder, which is applied in the field of metal powder metallurgy technology with embedded mesh core, can solve the problems of high scrap rate, disintegration of embryo body, low strength, etc., to reduce scrap rate, improve adhesion, connect high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

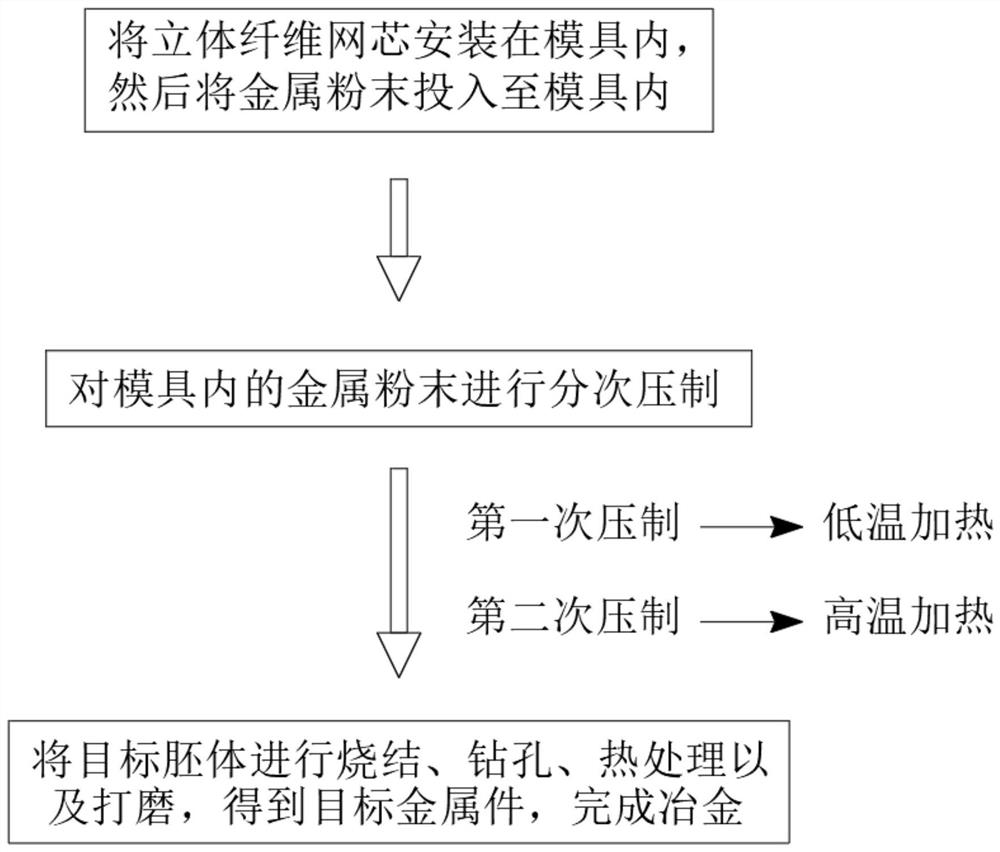

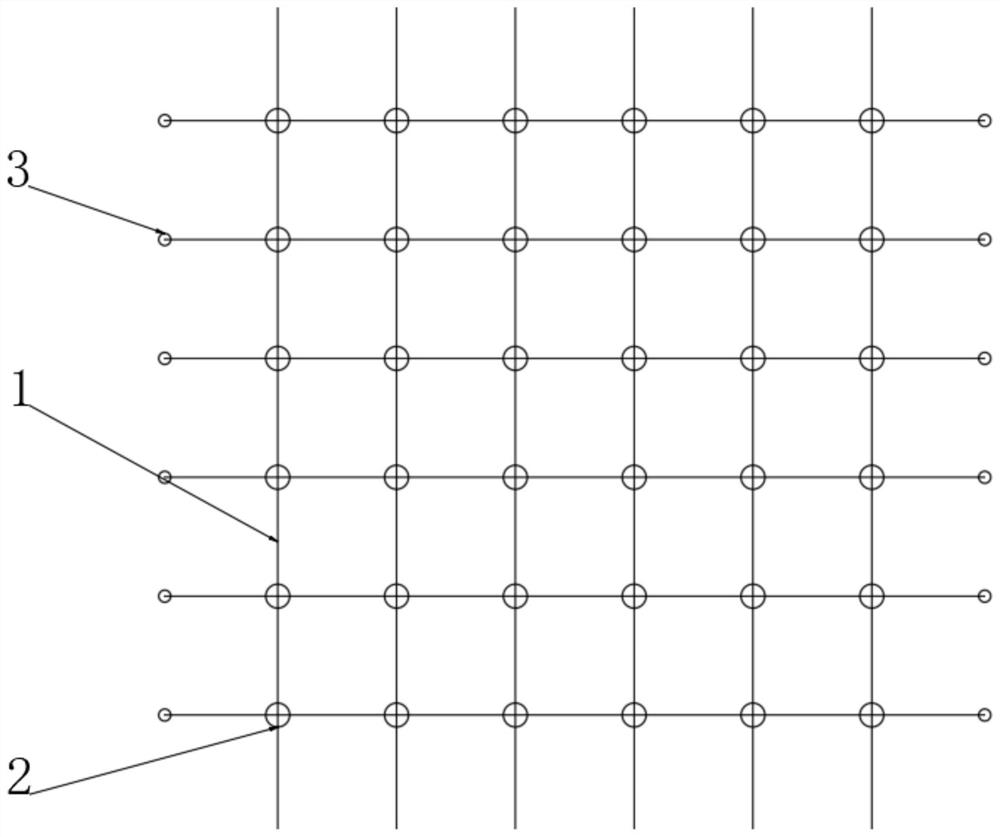

[0048] see figure 1 , an embedded mesh core type metal powder metallurgy process, comprising the following steps:

[0049] S1. First, install the three-dimensional fiber mesh core in a mold with thermal separation holes, and then put metal powder into the mold;

[0050] see Figure 5 , in the figure, a represents the mould, b represents the thermal separation hole, and c represents the hot melt adhesive. The specific steps for installing the three-dimensional fiber mesh core in step S1 are:

[0051] S11. First, insert the end of the heat-off rod of the three-dimensional fiber net core into the heat-off hole on the mold half, and then use hot melt glue to squeeze into the heat-off hole, so that the heat-off rod is glued into the heat-off hole;

[0052] S12. Then align the other half-mold with the thermal release rod on the other side and insert it to complete the installation of the three-dimensional fiber mesh core. The two half-molds form a whole mold for easy demoulding. ...

Embodiment 2

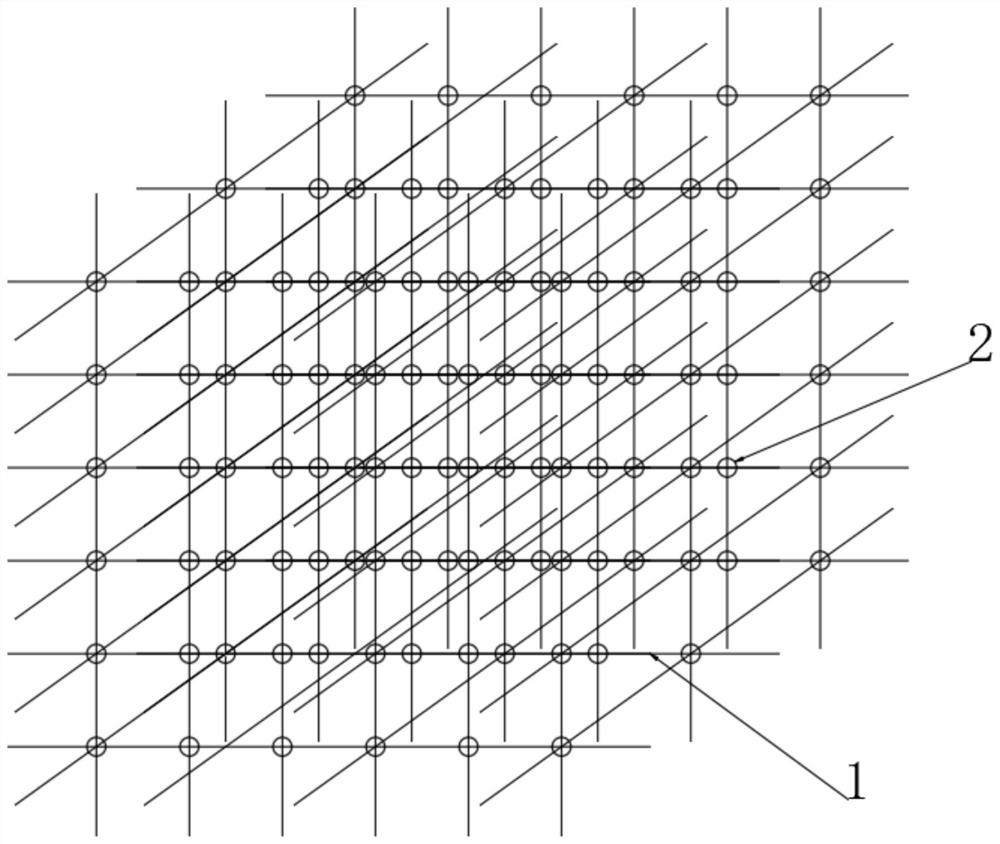

[0061] Compared with Embodiment 1, this embodiment is different in the specific setting structure of the reinforcing ball 2 .

[0062] The reinforcing ball 2 includes an upper sealing hard shell 81 and a lower transparent hard shell 82 fixedly connected to the lower end of the upper sealing hard shell 81, and high temperature resistant liquid glue is filled in the space surrounded by the upper sealing hard shell 81 and the lower transparent hard shell 82 , the lower transparent hard shell 82 is a porous structure, and the lower transparent hard shell 82 is wrapped with a hot-melt layer. The melting point of the hot-melt layer is 90-150°C. The hard shell 82 is transparent, and the high-temperature-resistant liquid glue directly overflows downward under the action of gravity. Compared with the previous setting of the reinforcing ball 2, the structure is simpler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com