Active-carbon-based sulfur-tolerant shift catalyst and preparation method of catalyst

A technology of sulfur-resistant transformation and activated carbon, which is applied in the direction of catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve stable performance, long life and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

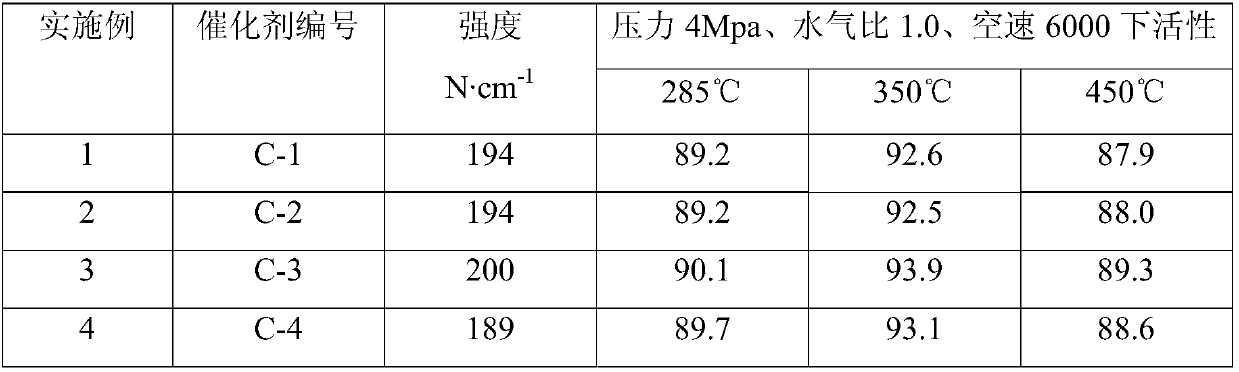

Examples

Embodiment 1

[0032] 500g Ca(OH) 2 Put it in a container, add 2Kg of deionized water, keep the temperature at 10°C, let it stand after stirring, and separate layers, take 1Kg of the supernatant and put it in the reaction kettle, add 3.8g of pseudo-boehmite and 46g of activated carbon, and stir for 10 minutes , Carbon dioxide was introduced while stirring, and after 2 hours of reaction, the mixture was released and filtered to obtain a filtered precipitate.

[0033] Dry the precipitate at 120°C, crush it to no less than 200 mesh, put it in a kneader, take 150ml of water, add 3ml of concentrated sulfuric acid, pour the water into the kneader, knead for 30 minutes, extrude, and dry , and calcined at 800°C for 3h under anaerobic conditions to obtain the carrier.

[0034] Place 6.5g of cobalt nitrate and 6.2g of ammonium heptamolybdate in 40ml of ammonia water to form a complex solution, impregnate the above-mentioned carrier in an equal amount, dry it naturally, and roast at 530°C for 3 hours ...

Embodiment 2

[0036] 400g Ca(OH) 2 Put it in a container, add 3Kg of deionized water, keep the temperature at 10°C, let it stand after stirring, and separate layers, take 2Kg of the supernatant and put it in the reaction kettle, add 7.6g of pseudo-boehmite and 92g of activated carbon, and stir for 10 minutes , Carbon dioxide was introduced while stirring, and after 1.8h of reaction, the mixture was released and filtered to obtain a filtered precipitate.

[0037] Dry the precipitate at 125°C, crush it to no less than 200 mesh, put it in a kneader, take 300ml of water, add 6ml of concentrated sulfuric acid, pour the water into the kneader, knead for 50 minutes, extrude, and dry , and calcined at 900°C for 2.5h under anaerobic conditions to obtain a carrier.

[0038] Place 13g of cobalt nitrate and 12.4g of ammonium heptamolybdate in 80ml of ammonia water to form a complex solution, impregnate the above-mentioned carrier in equal amounts, dry it naturally, and roast it at 550°C for 2.5h under...

Embodiment 3

[0040] 400g Ca(OH) 2 Put it in a container, add 2Kg of deionized water, keep the temperature at 10°C, let it stand after stirring, and separate layers, take 1Kg of the supernatant and put it in a reaction kettle, add 5.6g of pseudo-boehmite and 43g of activated carbon, and stir for 10 minutes , Carbon dioxide was introduced while stirring, and after 2.3h of reaction, the mixture was released and filtered to obtain a filtered precipitate.

[0041] Dry the precipitate at 110°C, crush it to no less than 200 mesh, put it in a kneader, take 150ml of water, add 3ml of concentrated sulfuric acid, pour the water into the kneader, knead for 40 minutes, extrude, and dry , and calcined at 750°C for 2h under anaerobic conditions to obtain the carrier.

[0042] Place 8.7g of cobalt nitrate and 7.0g of ammonium heptamolybdate in 40ml of ammonia water to form a complex solution, impregnate the above-mentioned carrier in equal amounts, dry it naturally, and roast it at 500°C for 2 hours unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com