A kind of preparation method of core-shell structure micro-nano fiber

A technology of micro-nanofiber and shell structure, applied in the direction of chemical characteristics of fibers, textile and papermaking, conjugated synthetic polymer rayon, etc., can solve the problem of low mechanical strength and modulus of extracellular matrix electrospun fibers, limited application and other problems to achieve the effect of enhancing cytocompatibility and biological activity and facilitating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the core-shell structure micro-nanofiber of the present invention relates to the preparation method of the polymer synthetic material / acellular matrix core-shell structure micro-nanofiber, which needs coaxial electrospinning technology, so the preparation method of the present invention needs to use coaxial needle.

[0023] In addition, the materials required by the present invention include: animal-derived decellularized matrix, polymer synthetic materials, fluorine-containing polar reagents, and the like.

[0024] The preparation method of the present invention is as follows:

[0025] (1) Preparation of acellular matrix powder.

[0026] Take fresh animal tissues and organs (animal species can be pigs, cattle, sheep and other poultry, tissues and organs include spinal cord, peripheral nerves, small intestinal mucosa, skin, etc.), cut into 1×1×1mm 3 ~2×2×2mm 3 Cubes were soaked in PBS solution containing 1% penicillin / streptomycin to sterili...

Embodiment 1

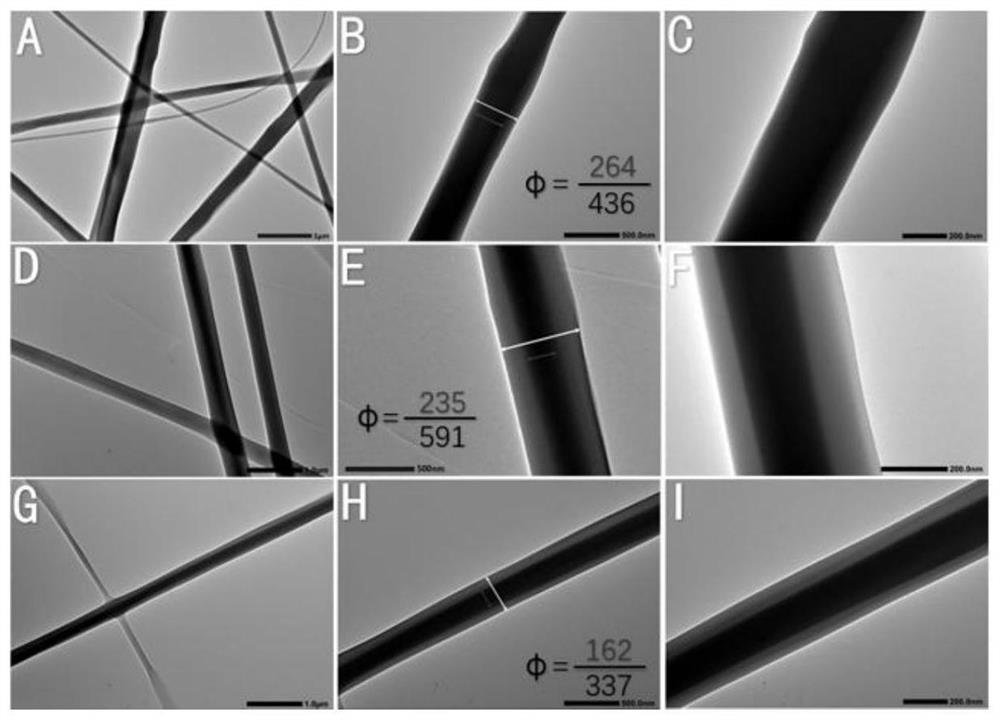

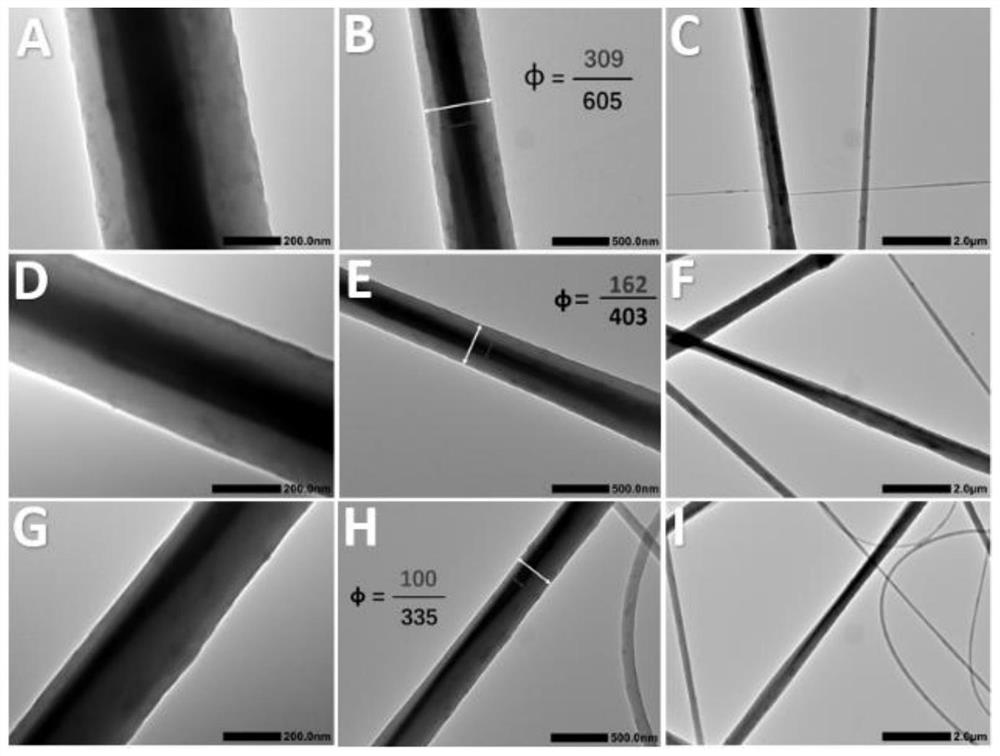

[0037] Example 1 Preparation of PCL / PDSM core-shell structure micro-nanofibers

[0038] (1) Preparation of acellular matrix powder from porcine upper layer skin.

[0039] Take fresh pig-derived upper skin, cut into 2×2×2mm 3 Cube, soaked in PBS solution containing 1% penicillin / streptomycin and sterilized overnight; the next day, it was washed 3 times in deionized water, each time for 5 minutes, and then soaked in 3% tritonX-100 for 12 hours; the tissue was taken out and deionized Wash with water for 3 times, each time for 15 minutes, and then put into 4% sodium deoxycholate solution for 24 hours to prepare the decellularized matrix (DCM) of animal tissue.

[0040] Wash the acellular matrix (DCM) of animal tissue prepared above with deionized water for 15 min×3 times, and freeze-dry in vacuum for 2-3 days; degrease the freeze-dried DCM with dichloromethane / ethanol (2:1) After soaking for 12 hours×2 times, wash with deionized water for 15 minutes×3 times, vacuum filter overni...

Embodiment 2

[0055] Example 2 Preparation of PCL / DSCM core-shell structure micro-nanofibers

[0056] (1) Preparation of porcine spinal cord acellular matrix powder.

[0057] Take fresh porcine spinal cord tissue, cut into 1×1×1mm 3 Cube, soaked in PBS solution containing 1% penicillin / streptomycin and sterilized overnight; the next day, it was washed 3 times in deionized water, each time for 5 minutes, and then soaked in 3% tritonX-100 for 12 hours; the tissue was taken out and deionized Wash with water for 3 times, each time for 15 minutes, and then put into 4% sodium deoxycholate solution for 24 hours to prepare the decellularized matrix (DCM) of animal tissue.

[0058] Wash the acellular matrix (DCM) of animal tissue prepared above with deionized water for 15 min×3 times, and freeze-dry in vacuum for 2-3 days; degrease the freeze-dried DCM with dichloromethane / ethanol (2:1) After soaking for 12 hours×2 times, wash with deionized water for 15 minutes×3 times, vacuum filter overnight, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com