Preparation and usage of hollow cellulose gas humidification membrane

A technology of gas humidification and cellulose, applied in the fuel cell gas humidification system, the preparation field of cellulose hollow fiber gas humidification membrane, which can solve the problem of acid and alkali resistance, organic solvent resistance, and limited application fields , environmental pollution and other issues, to achieve the effect of good acid and alkali resistance, good application prospects, and strong hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 10 grams of cellulose (average degree of polymerization ≈ 1000), 0.05 g of propyl gallate (0.5% of the weight of the cellulose) was added to 90 grams of MMNO·H 2 In O, stir at 80°C for 24hr under the protection of nitrogen to dissolve completely. After vacuum defoaming, a casting solution with a cellulose concentration of 10wt.% is obtained, and then put into a spinning tank for wet spinning. The spinning temperature is 80°C, the core fluid is deionized water, the flow rate is 0.4ml / min, the gel bath is water, and the temperature of the water bath is room temperature. The spun cellulose hollow fiber membranes were washed in flowing deionized water for 24 hours and then dried in air. Scanning electron microscopy showed that the film was homogeneous and dense (such as figure 1 ). The inner / outer diameter of the hollow fiber membrane is 0.42mm / 0.72mm, and the thickness of the dense layer is 0.15mm.

[0034] The gas permeation rate of the prepared dense cellulose hollow ...

Embodiment 2

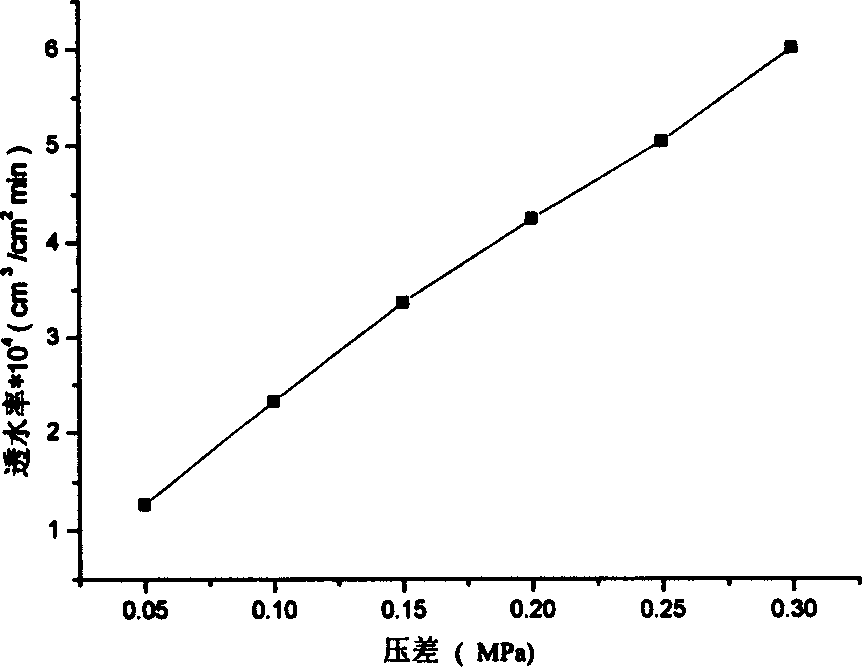

[0048] Such as figure 2 As shown, the cellulose hollow air humidification membrane prepared in Example 1 is assembled into a module suitable for a 5KW fuel cell stack humidification system, and the total area of the membrane is 7000cm 2 . When the water-air pressure difference is 0.1MPa, the water permeability of the module reaches 1.6ml / min, which can meet the humidification requirements of raw gas. At the same time, when the dew point of the raw material gas is -15°C, the humidification performance at the maximum gas flow rate under different gas pressures and the influence of the gas flow rate on the humidification performance at 0.2 MPa are tested, and the results show a good humidification effect. The specific results are attached image 3 , 4 , 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com