Retanning agent for improving tearing strength of leather and preparation method of retanning agent

A technology of tear resistance and retanning agent, which is applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, animal husbandry, etc. Problems such as protein interaction, inability to obtain products with stable performance, short alkyl chain length, etc., to achieve the effect of superior performance, soft film formation and high tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

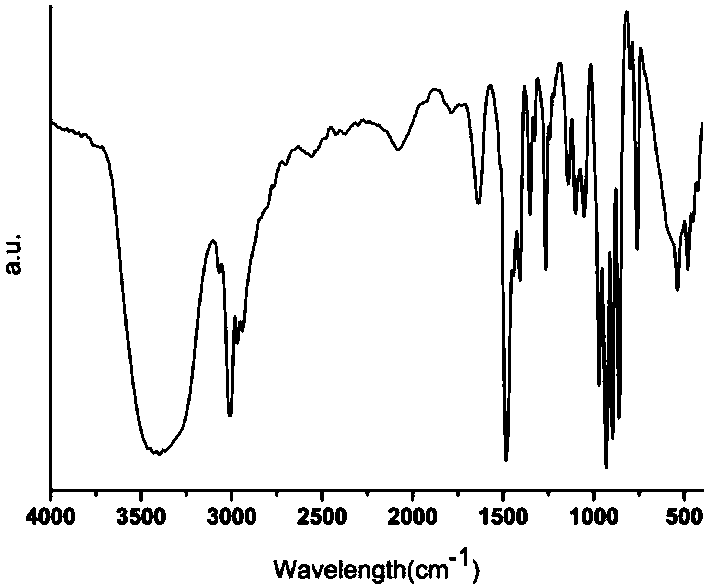

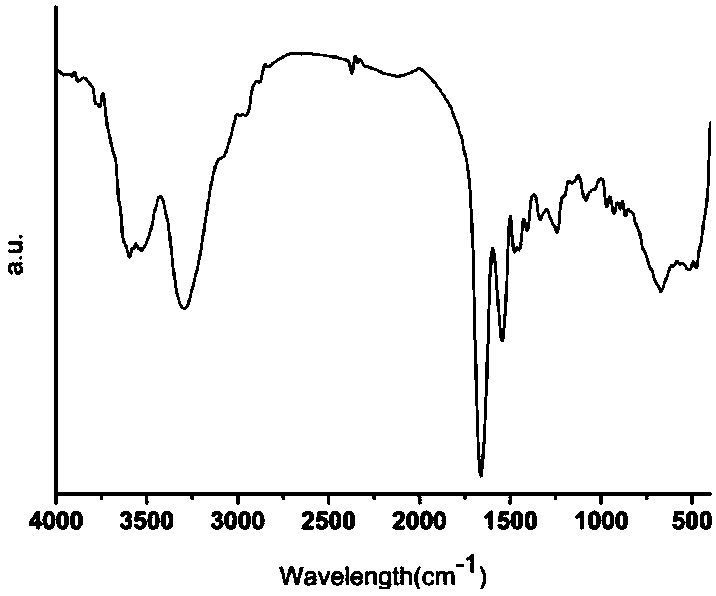

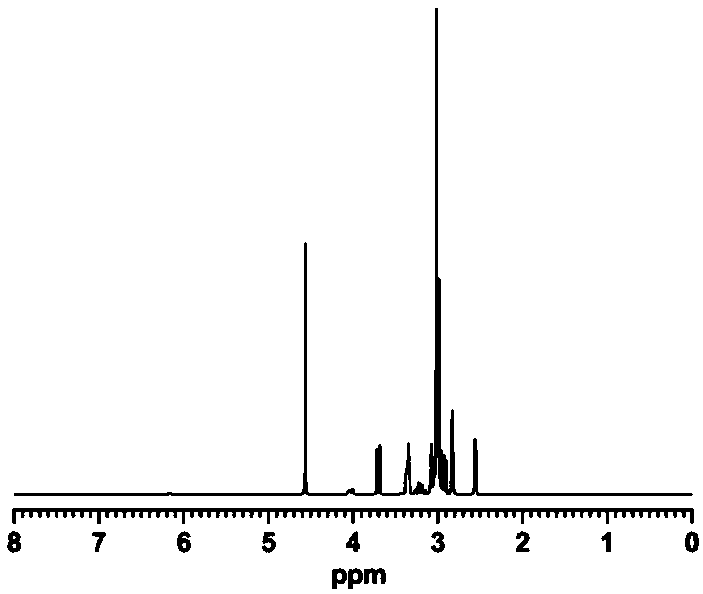

Image

Examples

Embodiment 1

[0042] Add 0.178g of potassium sulfate, 9.45g of 3-chloro-1,2-epoxychloropropane, 17ml of methanol, and distilled water into a 250ml three-neck reaction flask equipped with a thermometer socket, a dropping funnel socket, and a condenser socket, and stir with a magnetic force. After stirring and heating to 50°C, open the dropping funnel and continue to add 7.3g of dimethylethylamine dropwise for 30 minutes. After the dropwise addition, keep stirring and heating at a constant temperature of 50°C for 1.5h. The resulting product is poured into a 250ml round-bottomed flask equipped with a distillation head, a thermometer socket, and a condenser socket, and ethylene monochloride (6.45g) is added to react to prepare 2,3-epoxypropylethylmethyl ethylamine chloride , assemble the apparatus and carry out vacuum distillation. Finally, it is purified by Soxhlet extractor to obtain quaternary ammonium salt.

[0043] Take 10g of gelatin and 190g of distilled water into a 250ml round bottom ...

Embodiment 2

[0049] The described method is consistent with that of Example 1, the only difference is that the ratio between the epoxy group and the primary amino group is changed to a material ratio of 0.5:1.

[0050] Add ethanol to the obtained feed solution and mix evenly. The volume ratio of ethanol to the mixed solution is 1:4. Place it in a normal pressure oven at 50°C and dry for 6 hours to obtain a gelatin film with a contact angle of 97°. The gelatin film is hydrophobic. .

Embodiment 3

[0052] The described method is consistent with that of Example 1, the only difference is that the ratio between the epoxy group and the primary amino group is changed to a material ratio of 1:1.

[0053] Add ethanol to the obtained feed solution and mix evenly. The volume ratio of ethanol to the mixed solution is 1:4. Place it in a normal pressure oven at 50°C and dry for 6 hours to obtain a gelatin film with a contact angle of 103.02°. The gelatin film is hydrophobic. , and the hydrophobicity is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com