Biaxially oriented polypropylene waterproof breathable film and preparation method thereof

A waterproof and breathable film, two-way stretching technology, applied in the field of film manufacturing, can solve the problems of poor toughness and adhesion of the film, uneven hole formation on the surface of the film, and difficult non-woven composite, etc., to achieve good electrical insulation, vertical and horizontal The effect of uniform and stable performance and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

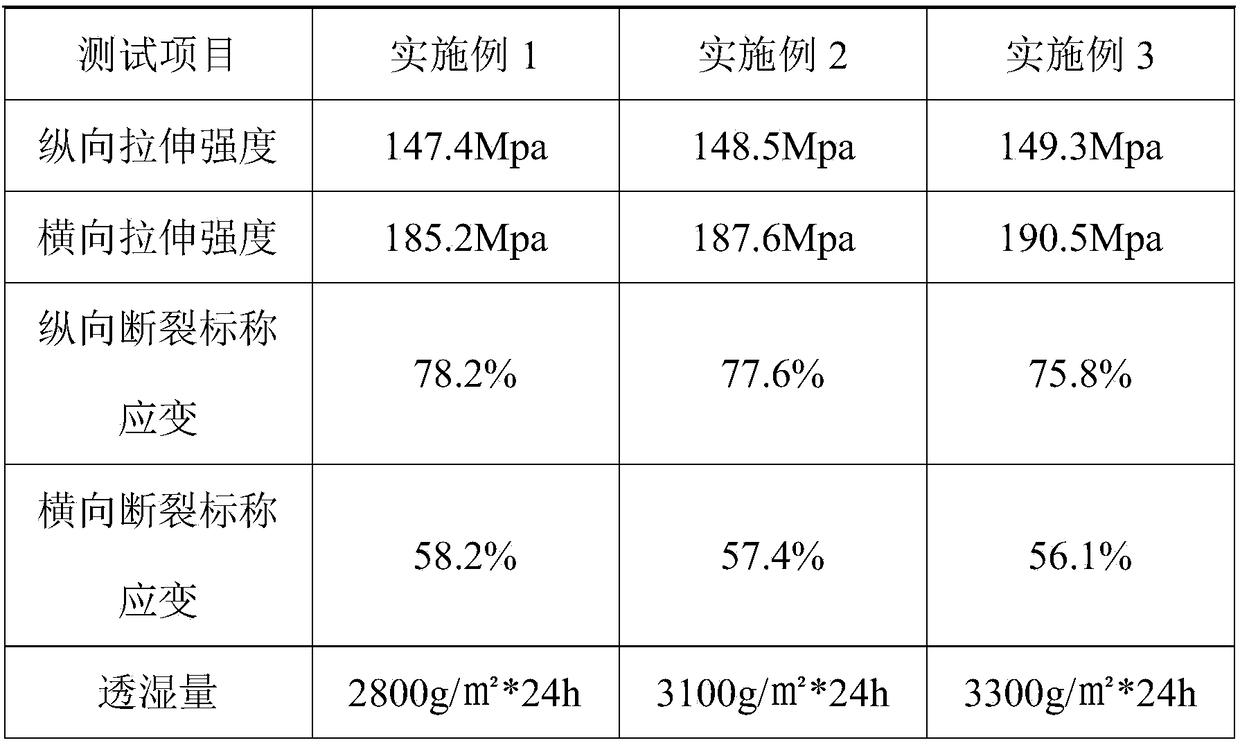

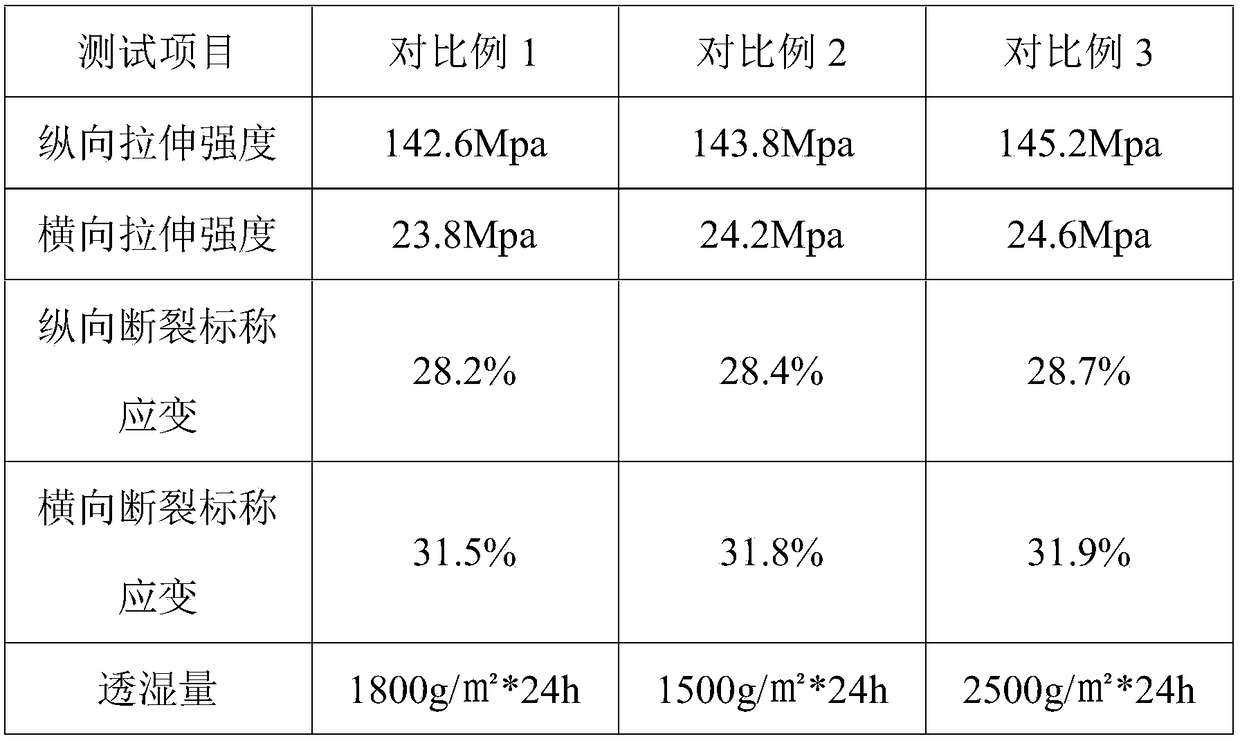

Examples

Embodiment 1

[0025] The preparation method of the biaxially stretched polypropylene waterproof breathable membrane of the present embodiment comprises the following steps:

[0026] S1. Take 30 parts of homopolypropylene resin, 50 parts of heavy calcium carbonate powder, 1 part of coupling agent, 10 parts of linear low-density polyethylene resin and 12 parts of low-density polyethylene, mix and extrude to make pellets, Then it is added to the twin-screw extruder; in the twin-screw extruder, it is heated at 240-242°C to become a molten state, and the resulting melt is filtered through a 400-mesh filter and extruded into a film through a single-layer die. A high-pressure air knife attaches the diaphragm to a chilled roller for rapid cooling to form a cast sheet.

[0027] S2. The cast sheet prepared in step S1 is preheated at 130-132° C., and then longitudinally stretched 4.5 times at 120-122° C. to obtain a thick film.

[0028] S3. After the thick film prepared in step S2 is preheated at 175...

Embodiment 2

[0031] The preparation method of the biaxially stretched polypropylene waterproof breathable membrane of the present embodiment comprises the following steps:

[0032] S1, get 31 parts of homopolypropylene resin, 51 parts of heavy calcium carbonate powder, 1 part of coupling agent, 8 parts of linear low density polyethylene resin and 10 parts of low density polyethylene and mix and extrude to make pellets, then Add it to the twin-screw extruder; in the twin-screw extruder, it is heated at 242-246°C to become a molten state, and the obtained melt is filtered through a 400-mesh filter, and then extruded into a film through a single-layer die. The air knife attaches the film to the chilled roller and quenches it to form a cast sheet.

[0033] S2. The cast sheet obtained in step S1 is preheated at 132-136° C., and then longitudinally stretched 4.8 times at 122-126° C. to obtain a thick film.

[0034] S3. After the thick film prepared in step S2 is preheated at 177-178°C, it is tr...

Embodiment 3

[0037] The preparation method of the biaxially stretched polypropylene waterproof breathable membrane of the present embodiment comprises the following steps:

[0038] S1, get 32 parts of homopolypropylene resin, 52 parts of heavy calcium carbonate powder, 2 parts of coupling agent, 5 parts of linear low-density polyethylene resin and 6 parts of low-density polyethylene and mix and extrude to make pellets, then Add it to the twin-screw extruder; in the twin-screw extruder, heat it to a molten state at 246-250 ° C, and the resulting melt is filtered through a 400-mesh filter, and then extruded into a film through a single-layer die. The air knife attaches the film to the chilled roller and quenches it to form a cast sheet.

[0039] S2. The cast sheet obtained in step S1 is preheated at 136-140° C., and stretched longitudinally at 126-130° C. by 5.2 times to obtain a thick film.

[0040] S3. After the thick film prepared in step S2 is preheated at 178-180°C, it is transversel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com