Polyacrylate emulsion adhesive and preparation method thereof

A polyacrylate emulsion and adhesive technology, which is applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the defects of alkali resistance and chemical stability, and the alkali resistance of polyacrylate emulsion adhesives , slow progress in chemical stability, adhesive film adhesion and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The present invention also provides a preparation method of the polyacrylate emulsion adhesive described in the above technical scheme, comprising the following steps:

[0071] a) Mix the polymerized monomer, polymerization regulator, water, reactive emulsifier, nonionic emulsifier, γ-glycidyl etheroxypropyltrimethoxysilane and stabilizer, and carry out emulsion polymerization under the action of an initiator, Obtain polyacrylate emulsion adhesive;

[0072] The reactive emulsifier is 1-allyloxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ether ammonium sulfate;

[0073] The nonionic emulsifier is an APEO-containing nonionic emulsifier.

[0074] In the present invention, the polymerization monomer, polymerization regulator, water, reactive emulsifier, nonionic emulsifier, γ-glycidyl etheroxypropyl trimethoxysilane, stabilizer and initiator are all related to the above-mentioned technology It is the same as that described in the scheme and will not be repeated her...

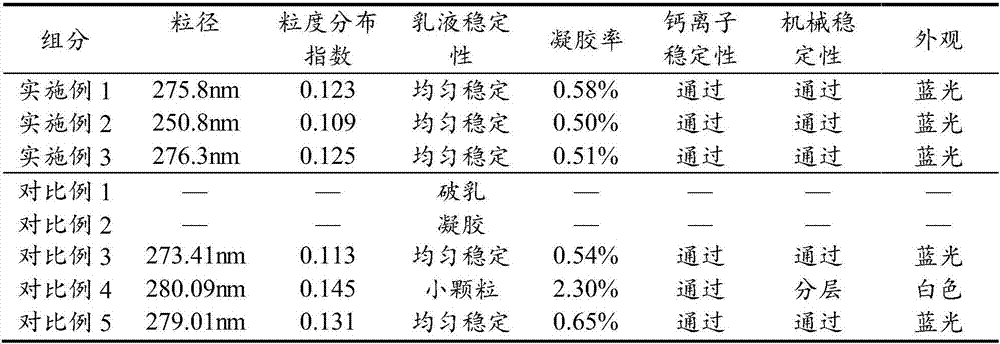

Embodiment 1

[0098] (1) Raw material ratio and source:

[0099] N-methylolacrylamide (N-AM) 2g, provided by Tianjin Damao Chemical Reagent Factory;

[0100] Isooctyl acrylate (2~EHA) 43g, provided by Shanghai Aladdin Chemical Co., Ltd.;

[0101] Butyl acrylate (BA) 32g is provided by Tianjin Damao Chemical Reagent Factory;

[0102] Methyl methacrylate (MMA) 15g is provided by Tianjin Damao Chemical Reagent Factory;

[0103] Polymaleic acid (HPMA) 4g, provided by Tianjin Damao Chemical Reagent Factory;

[0104] Acrylic acid (AA) 4g, provided by Tianjin Damao Chemical Reagent Factory;

[0105] Dodecanethiol 0.2g, provided by Shanghai Aladdin Chemical Co., Ltd.;

[0106] Deionized water (DW) 150g, self-made;

[0107] Reactive emulsifier (DNS-86) 0.43g, provided by Guangzhou Bangrun Chemical Technology Co., Ltd.;

[0108] Nonionic emulsifier (DP-100) 0.43g, provided by Guangzhou Bangrun Chemical Technology Co., Ltd.;

[0109] Ammonium persulfate (APS) 0.55g is provided by Tianjin Damao ...

Embodiment 2

[0118] (1) Raw material ratio:

[0119] N-methylolacrylamide (N-AM) 2g;

[0120] Isooctyl acrylate (2~EHA) 43g;

[0121] Butyl acrylate (BA) 32g;

[0122]Methyl methacrylate (MMA) 15g;

[0123] Polymaleic acid (HPMA) 4g;

[0124] Acrylic acid (AA) 4g;

[0125] n-dodecanethiol 0.2g;

[0126] Deionized water (DW) 150g;

[0127] Reactive emulsifier (DNS-86) 0.6g;

[0128] Non-ionic emulsifier (DP-100) 0.6g;

[0129] Ammonium persulfate (APS) 0.55g;

[0130] γ~glycidyl etheroxypropyl trimethoxysilane (KH560) 3g;

[0131] Sodium bicarbonate (NaHCO 3 ) 0.76g.

[0132] (2) Preparation method:

[0133] ① Configure 0.275g ammonium persulfate and 1.5g deionized water as the first initiator, and configure 0.275g ammonium persulfate and 7.5g deionized water as the second initiator;

[0134] ②Mix 0.45g DNS-86, 0.45g DP-100, 0.38g sodium bicarbonate and 58.5g deionized water, then add 2g N-hydroxyacrylamide, 43g isooctyl acrylate, 32g butyl acrylate, 15g formazan Acrylic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com