Preparation method of bamboo fiber paper cups

A bamboo fiber, paper cup technology, applied in non-fiber pulp addition, fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problem of consuming non-renewable wood resources, and achieve good oil resistance and The effect of resistance to organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

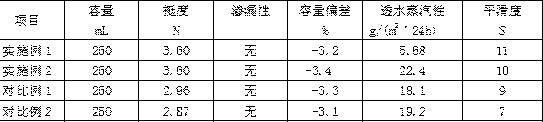

Examples

Embodiment 1

[0031] A bamboo fiber paper cup, comprising a cup body, the cup body includes an outer layer, an inner layer, a hollow layer arranged between the outer layer and the inner layer and a coating layer coated on the outer layer, the outer layer and the inner material include The component of following parts by weight: 40 parts of bleached bamboo fiber, 5 parts of larch fiber, 15 parts of modified starch, 5 parts of chitosan, 5 parts of talc, 2 parts of dispersant, 2 parts of guar gum, 2 parts of glyceride hydrolase, 2 parts of moisturizing enhancer; the hollow layer material includes the following components by weight: 40 parts of polypropylene hollow short fiber, 20 parts of larch fiber, 5 parts of chitosan, 5 parts Parts of talcum powder, 2 parts of dispersant; The coating layer material includes the following components in parts by weight: 10 parts of EVOH, 5 parts of polyglycolic acid, 5 parts of chitosan, 5 parts of talcum powder, 2 parts Dispersant.

[0032] A kind of prepa...

Embodiment 2

[0051] A bamboo fiber paper cup, comprising a cup body, including an outer layer, an inner layer, a hollow layer arranged between the outer layer and the inner layer and a coating layer coated on the outer layer, the outer layer and the inner material include the following weight Components in parts: 40 parts bleached bamboo fiber, 5 parts larch fiber, 15 parts modified starch, 5 parts chitosan, 5 parts talc, 2 parts dispersant, 2 parts guar gum, 2 parts glycerin 2 parts of moistening strength agent for ester hydrolase; the hollow layer material includes the following components in parts by weight: 30 parts of polypropylene hollow short fibers, 20 parts of larch fibers, 5 parts of chitosan and 5 parts of talcum powder, 2 parts of dispersant; the material of the coating layer includes the following components in parts by weight: 10 parts of EVOH, 5 parts of polyglycolic acid, 5 parts of chitosan, 2 parts of talcum powder, and 2 parts of dispersant.

[0052] A kind of preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com