Extraction method for antibacterial peptide

An extraction method and antimicrobial peptide technology, which is applied in the field of extraction of chemical raw materials, can solve the problems of antimicrobial peptides with many impurities, expensive antibacterial costs, and complicated processes, and achieve the effects of less impurities, sedative effect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

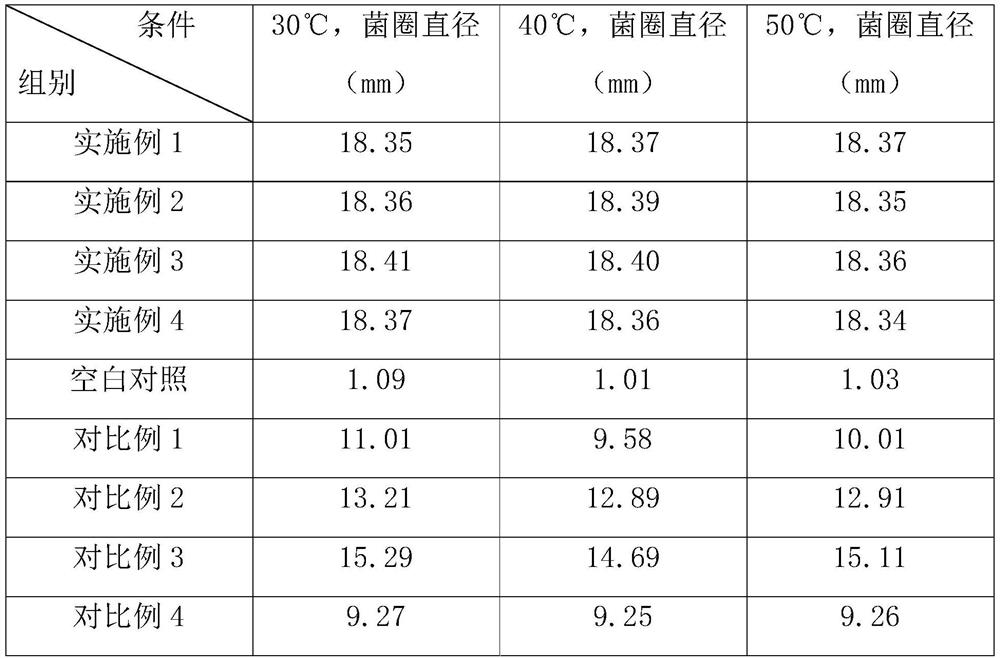

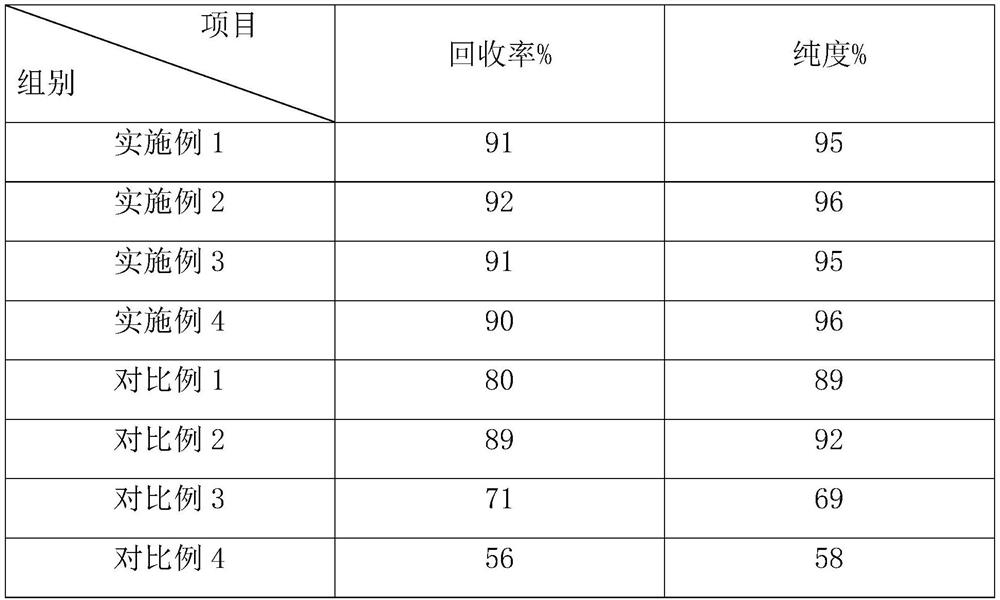

Examples

Embodiment 1

[0076]A method of extraction of antimicrobial peptides, the extraction method comprising the steps of:

[0077]According to the weight of the barley, purple alfalfa, pea, and sesame mixture, the total weight of plant raw materials is 8kg, including 1kg, peas, 2kg, sesame, and 4kg of peas, 2kg, 2kg of peas, 2kg of peas, 4kg, 2kg, 2kg, 2kg of peas, 2kg, 2kg of peas, 2kg, 2kg, 2kg of peas

[0078]The plant raw material was added to the treatment kettle, and a concentration of 8% acetic acid was added to the treatment kettle according to the ratio of the material weight ratio of 1: 15;

[0079]By the online control system, the temperature condition in the treatment kettle is 40 ° C; the pressure condition is 20 MPa; the power of the ultrasonic treatment conditions is 150W, the frequency is 45 kHz, the time is 20 min, and the first phase is processed, and the aperture is used. 15 nm ceramic film filtration to give the filtrate A;

[0080]0.01 g / ml of 0.01 g / ml (amount of the addition amount of t...

Embodiment 2

[0084]A method of extraction of antimicrobial peptides, the extraction method comprising the steps of:

[0085]According to the weight of the barley, the purple alfalfa, pea and sesame seeds are mixed with plant raw materials, and the total weight of plant raw materials is 14kg, of which 1kg of barley, 5kg, peas, 7kg, sesame seeds;

[0086]The plant raw material was added to the treatment kettle, and a concentration of 0.5% acetic acid was added to the treatment kettle according to the ratio of the material weight ratio of 1:30;

[0087]By the online control system, the temperature condition in the treatment kettle is 85 ° C; the pressure condition is 40 MPa; the power of the ultrasonic treatment conditions is 300W, the frequency is 45 kHz, the time is 45min, and the first phase is processed, the aperture is used. 35 nm ceramic film filtration to give the filtrate A;

[0088]0.09 g / ml of 0.09 g / ml (amount of filtrate A) was added to a papaino, cellulase, and mannanase mixed to obtain a comp...

Embodiment 3

[0092]A method of extraction of antimicrobial peptides, the extraction method comprising the steps of:

[0093]According to the weight of the barley, purple alfalfa, pea and sesame mixture with plant raw materials, total weight of plant raw materials, 1kg, 3kg, peas, 3kg, 3kg, peas;

[0094]The plant feedstock was added to the treatment kettle, and a concentration of 5% acetic acid was added to the treatment kettle according to the ratio of the material weight ratio of 1:20;

[0095]By the online control system, the temperature condition in the treatment kettle is 50 ° C; the pressure condition is 30 MPa; the power of the ultrasonic treatment conditions is 250W, the frequency is 40 kHz, the time is 35min, and the first phase is processed, the aperture is used. 25 nm of ceramic film filtration to give the filtrate A;

[0096]0.08 g / ml of the filtrate A (amount) of 0.08 g / ml of the filtrate A is added to a papaino, a cellulase, and mannanase mixed to obtain a composite enzyme, an enzymatic co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com