Lithium ion battery safety coating and application thereof as well as lithium ion battery

A lithium-ion battery, a safe technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of limited improvement effect, inability to be widely used, and inability to block heat-producing side reactions, and achieve excellent resistance. Effects of organic solvent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

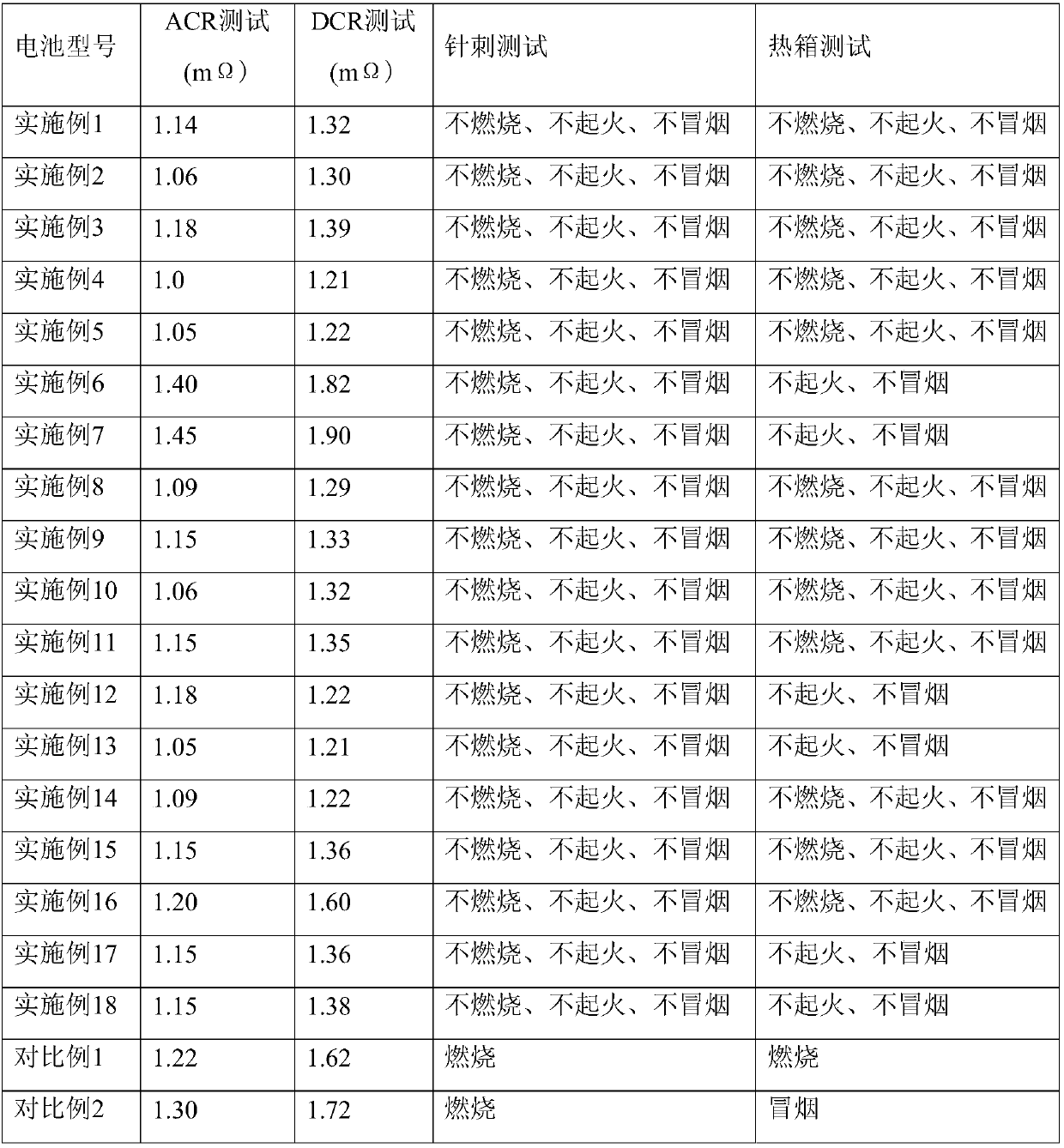

Examples

Embodiment 1

[0027] Preparation of lithium-ion battery safety coating: Add toluene 5 times the weight of polyethylene microspheres to polyethylene microspheres, add vinyl silane coupling agent to it, reflux reaction at 70°C for 20 hours, filter and dry to obtain poly Ethylene powder, then mix the polyethylene powder with the binder, and stir and disperse in turn to obtain a safety coating slurry; wherein, 0.5wt% of vinyl silane coupling agent, 2wt% of binder, and 97.5wt of polyethylene microspheres %, polyethylene microspheres are D 50 = 0.2 μm low-density polyethylene microspheres, the vinyl silane coupling agent is trimethoxy vinyl silane, and the binder is styrene-butadiene rubber.

[0028] Safety coating coating: the positive electrode sheet is coated with the safety coating slurry to prepare a positive electrode sheet with a safety coating, and the coating thickness is 2 μm.

[0029] Assembling the test cell: prepare the battery with the negative electrode sheet, positive electrode s...

Embodiment 2

[0031] Preparation of lithium-ion battery safety coating: Add toluene 5 times the weight of polyethylene microspheres to polyethylene microspheres, add vinyl silane coupling agent to it, reflux reaction at 70°C for 20 hours, filter and dry to obtain poly Ethylene powder, then mix the polyethylene powder with the binder, and stir and disperse in turn to obtain a safety coating slurry; wherein, 0.5wt% of vinyl silane coupling agent, 2wt% of binder, and 97.5wt of polyethylene microspheres %, polyethylene microspheres are D 50 = 0.2 μm low-density polyethylene microspheres, the vinyl silane coupling agent is trimethoxy vinyl silane, and the binder is styrene-butadiene rubber.

[0032] Safety coating coating: the safety coating slurry is applied to the negative electrode sheet to prepare a positive electrode sheet with a safety coating, and the coating thickness is 2 μm.

[0033] Assembling the test cell: prepare the battery with the negative electrode sheet, positive electrode sh...

Embodiment 3

[0035] Preparation of lithium-ion battery safety coating: Add toluene 5 times the weight of polyethylene microspheres to polyethylene microspheres, add vinyl silane coupling agent to it, reflux reaction at 70°C for 20 hours, filter and dry to obtain poly Ethylene powder, then mix the polyethylene powder with the binder, and stir and disperse in turn to obtain a safety coating slurry; wherein, 0.5wt% of vinyl silane coupling agent, 2wt% of binder, and 97.5wt of polyethylene microspheres %, polyethylene microspheres are D 50 = 0.2 μm low-density polyethylene microspheres, the vinyl silane coupling agent is trimethoxy vinyl silane, and the binder is styrene-butadiene rubber.

[0036] Safety coating coating: the positive electrode sheet is coated with safety coating slurry to obtain a positive electrode sheet with a safety coating, and the coating thickness is 4 μm, and the negative electrode sheet is coated with a safety coating slurry to obtain a positive electrode sheet with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com