Functional ionic liquid modified lipase and modification method thereof

A technology of ionic liquid and lipase, which is applied in the direction of hydrolytic enzymes, etc., can solve the problems of long cycle and complicated operation, and achieve the effect of short cycle, simple operation and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]1) Synthesis of 1-methyl-3-carboxyethylimidazolium chloride salt: According to Jean Pierre Bazureau et al. (Rate accelerations of 1,3-dipolar cyclodition reactions in ionic liquids. Tetrahedron Letters, 2000, 41: 7351-7355. ) to prepare 1-methyl-3-carboxyethylimidazolium chloride salt with a yield of 78.3% and a purity of 98.8%.

[0034] 2) Activation of functionalized ionic liquid: 0.17g of 1-methyl-3-carboxyethylimidazolium chloride salt, 0.192g of EDC·HCL and 0.115g of NHS were dissolved in 10ml of MES, and reacted at 30°C for 1h.

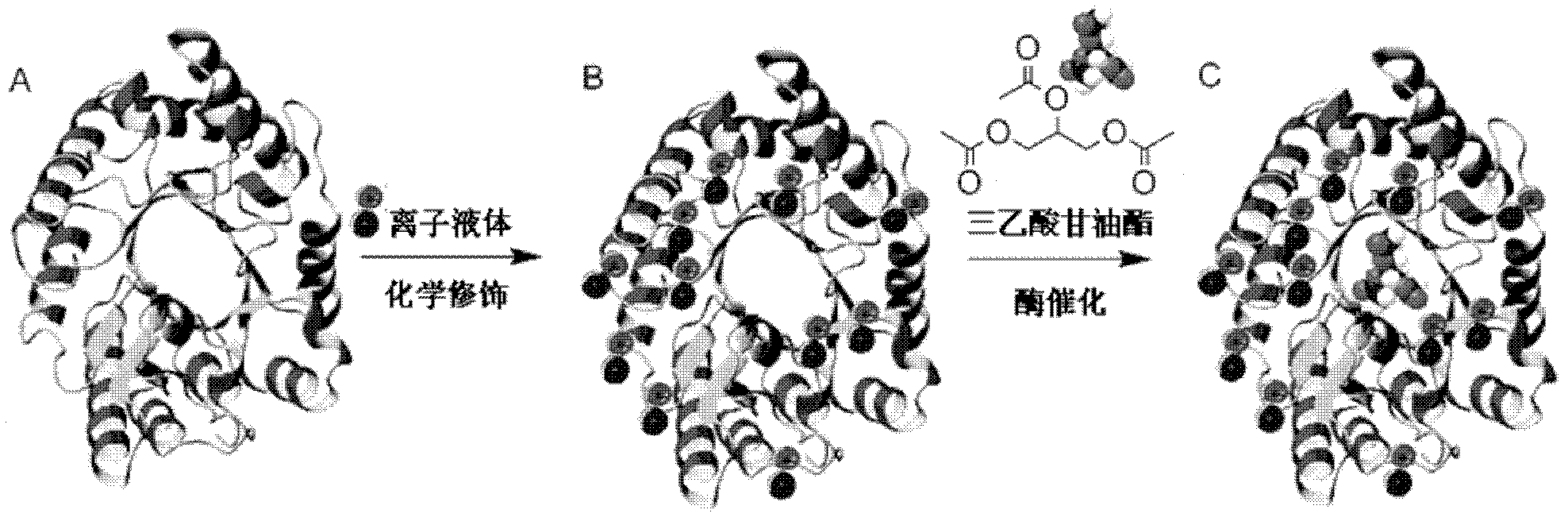

[0035] 3) Enzyme modification: The activated functionalized ionic liquid and the purified porcine pancreatic lipase were mixed and reacted at a molar ratio of 200:1, the reaction temperature was controlled at 0-4°C, the reaction time was 4 hours, and the excess modification was removed by ultrafiltration and centrifugation agent, concentrated enzyme.

[0036] 4) Determination of enzyme activity:

[0037] Lipase hydrolysis of triacetin em...

Embodiment 2

[0049] 1) Synthesis of 1-ethyl-3-carboxyethyl imidazolium chloride salt: according to Jean Pierre Bazureau et al. (Rate accelerations of 1,3-dipolar cycloloaddition reactions in ionic liquids. Tetrahedron Letters, 2000, 41: 7351-7355 .) to prepare 1-ethyl-3-carboxyethylimidazolium chloride salt with a yield of 71.6% and a purity of 97.6%.

[0050] 2) Activation of the functionalized ionic liquid: 0.18g of 1-ethyl-3-carboxyethylimidazolium chloride salt, 0.288g of EDC·HCL and 0.115g of NHS were dissolved in 10ml of MES, and reacted at room temperature for 1.5h.

[0051] 3) Enzyme modification: The activated functionalized ionic liquid and the purified Rhizopus lipase were mixed and reacted at a molar ratio of 300:1, the reaction temperature was controlled at 0-4°C, the reaction time was 6h, and excess modification was removed by ultrafiltration and centrifugation agent, concentrated enzyme.

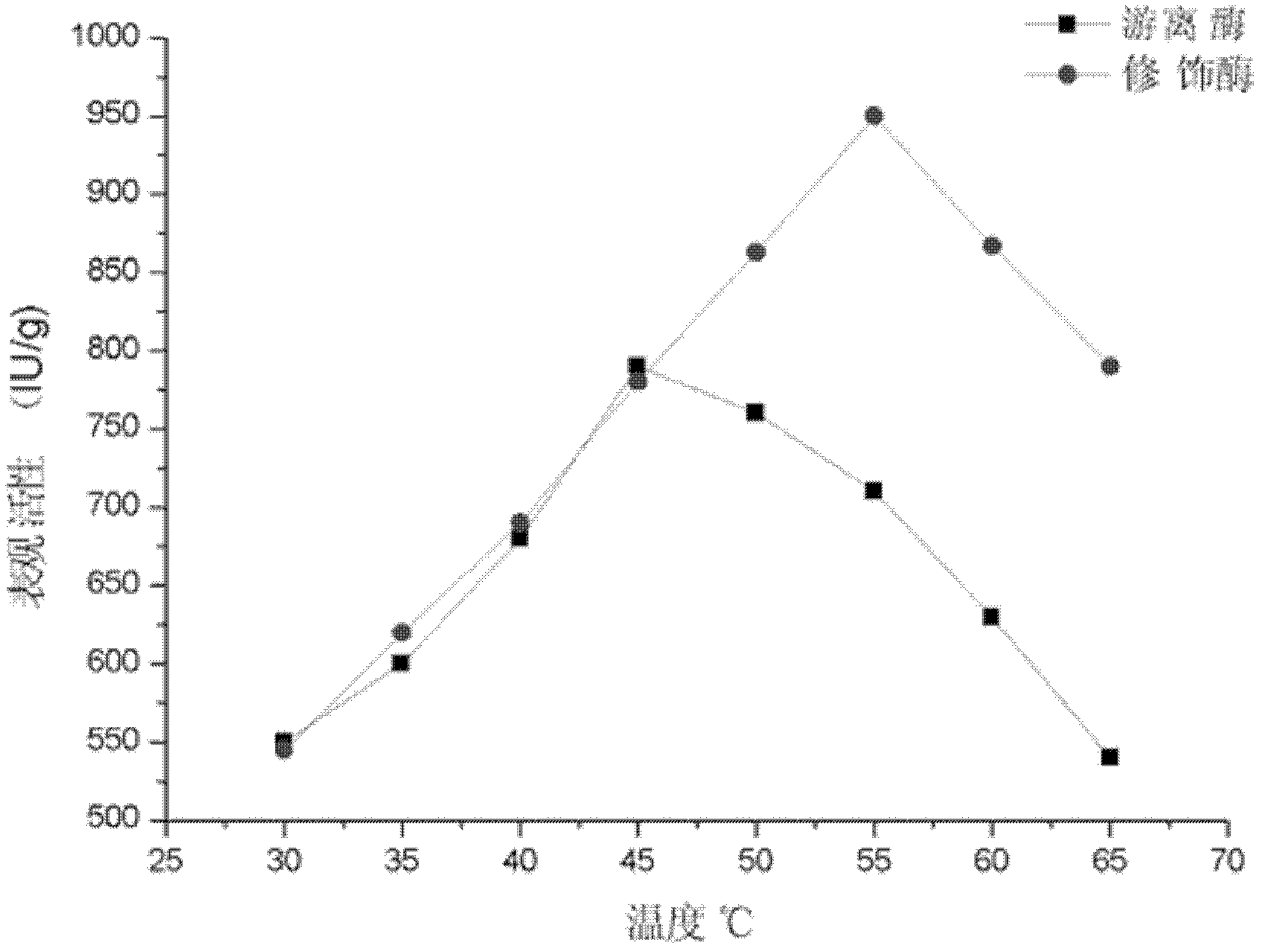

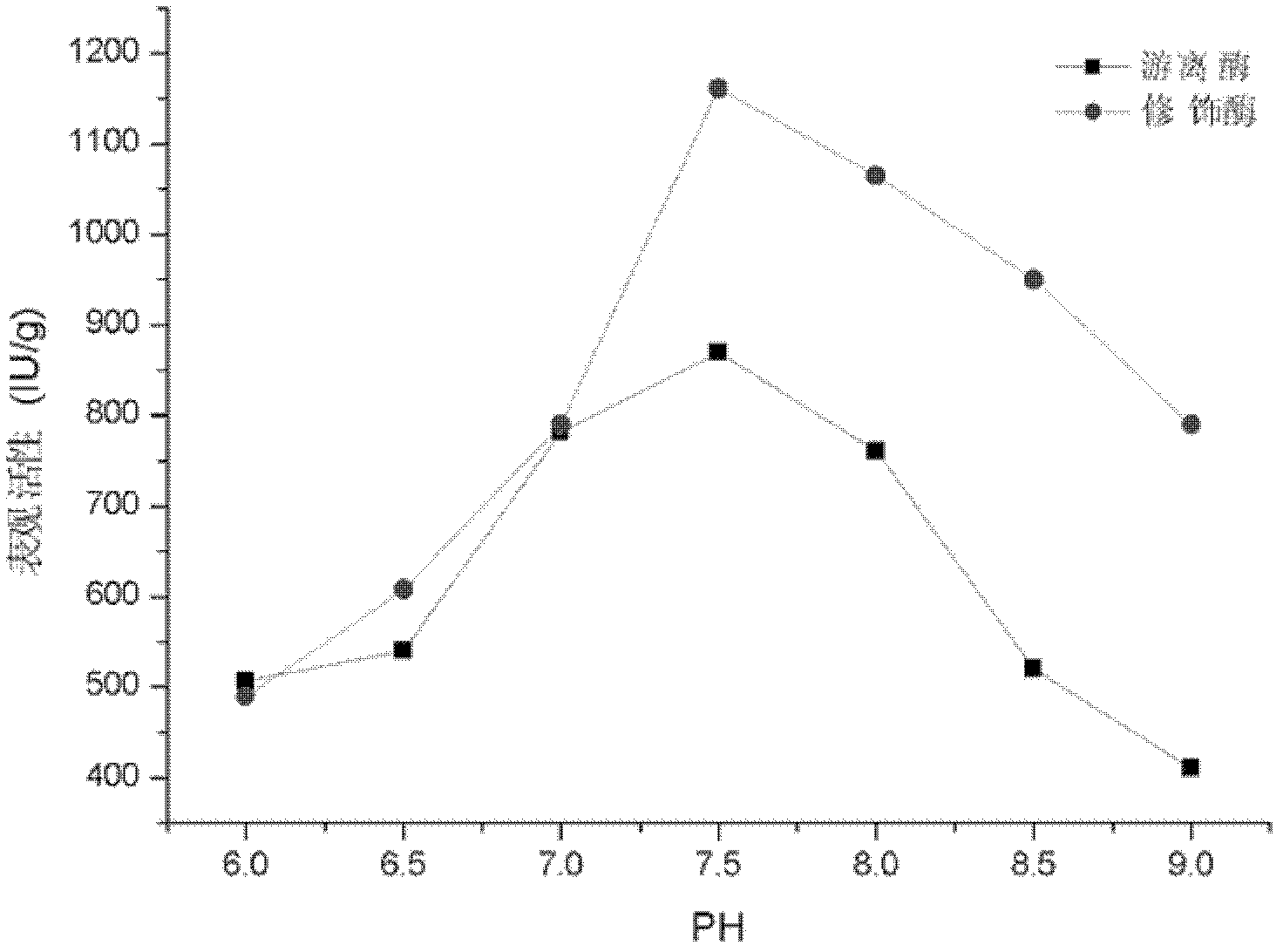

[0052] 4) Same operating conditions as in Example 1 for preparing the modified enzyme...

Embodiment 3

[0054] 1) Synthesis of chlorinated 1-methyl-3-(3-aminopropyl) imidazole: according to the description of Wu Youting et al. 1-Methyl-3-(3-aminopropyl)imidazole chloride was obtained with a yield of 82.7% and a purity of 98.1%.

[0055] 2) Enzyme modification: Dissolve 0.18g of 1-methyl-3-(3-aminopropyl)imidazole chloride, 1.44mg of EDC·HCL, 0.58mg of NHS and 0.165g of Pseudomonas cepacia lipase in 10ml of MES, and react The temperature is controlled at 0-4°C, the reaction time is 4 hours, excess modifiers are removed by ultrafiltration and centrifugation, and the enzyme is concentrated.

[0056] 3) The operating conditions for preparing the modified enzyme in Example 1 are the same, the apparent activity of the functionalized ionic liquid modified Pseudomonas cepacia lipase is 28501U / g lipase, while the free Pseudomonas cepacia lipase The enzyme activity is 2240lU / g lipase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com