Thermosetting anti-welding printing ink with low dielectric constant and dielectric loss and preparation method of thermosetting anti-welding printing ink

A low dielectric constant, solder resist ink technology, used in inks, household appliances, applications, etc., can solve the problems of poor high-frequency characteristics and cannot be applied to high-frequency electronic equipment, and achieve the effect of good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

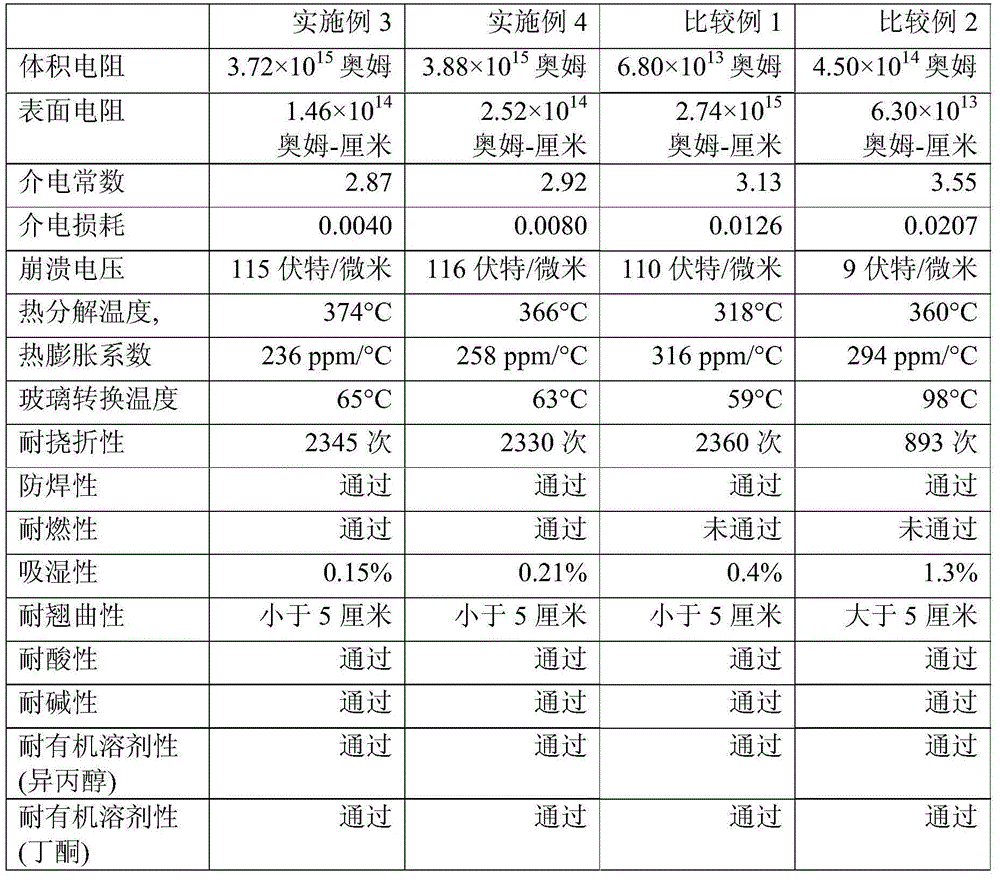

Examples

Embodiment 1

[0023] The preparation of the modified polyimide of embodiment 1

[0024] First, 25 grams of aliphatic diamine monomers with 36 carbons in the main chain and 12 grams of 4,4'-biphenyl ether dianhydride monomers were mixed in a mixture of 60 grams of n-methylpyrrolidone and 6.5 grams of naphtha In the constituted aprotic solvent, a first solution is formed. After the first solution was heated to 70° C. for 1 hour, 1 g of 3,5-diaminobenzoic acid monomer was added to form a second solution. The second solution was kept warm at 70° C. for 1 hour, and then 2.5 g of trimellitic anhydride monomer was added to form a third solution. The third solution was kept at 70° C. for 1 hour to obtain polyamic acid.

[0025] Then, 0.2 g of triphenylphosphine (triphenyl phosphine, TPP) and 15 g of toluene were mixed with the polyamic acid to form a pre-reaction solution. The pre-reaction solution was subjected to a cyclization reaction at 150° C. for 3 hours to obtain an intermediate product. ...

Embodiment 2

[0026] The preparation of the modified polyimide of embodiment 2

[0027] This embodiment is generally the same as Example 1, but the preparation of the modified polyimide of this embodiment is different from that of Example 1 in that: this embodiment is 20 grams of main chain containing aliphatic bismuth with 36 carbon numbers The amine monomer, 12 grams of 4,4'-diphenyl ether dianhydride monomer and 6.5 grams of naphtha were mixed in 60 grams of N-methylpyrrolidone to form a first solution.

Embodiment 3

[0028] Embodiment 3 Preparation of thermosetting solder resist ink

[0029] Get the modified polyimide 40 grams of embodiment 1, mix with 0.25 gram triphenyl phosphite, 0.5 gram pigment, 0.15 gram defoamer, 4 gram flame retardant and 3.6 gram novolak type epoxy resin, obtain Thermoset solder resist ink. Among them, triphenylphosphine is the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com