A kind of aqueous polysiloxane resin and preparation method thereof

A polysiloxane resin, water-based technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of poor emulsion stability, poor wear resistance, and few similar products, and achieve good stability, improved stability, and durability Alkaline and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A water-based polysiloxane resin prepared from A pre-emulsion, B emulsion and C solution as raw materials:

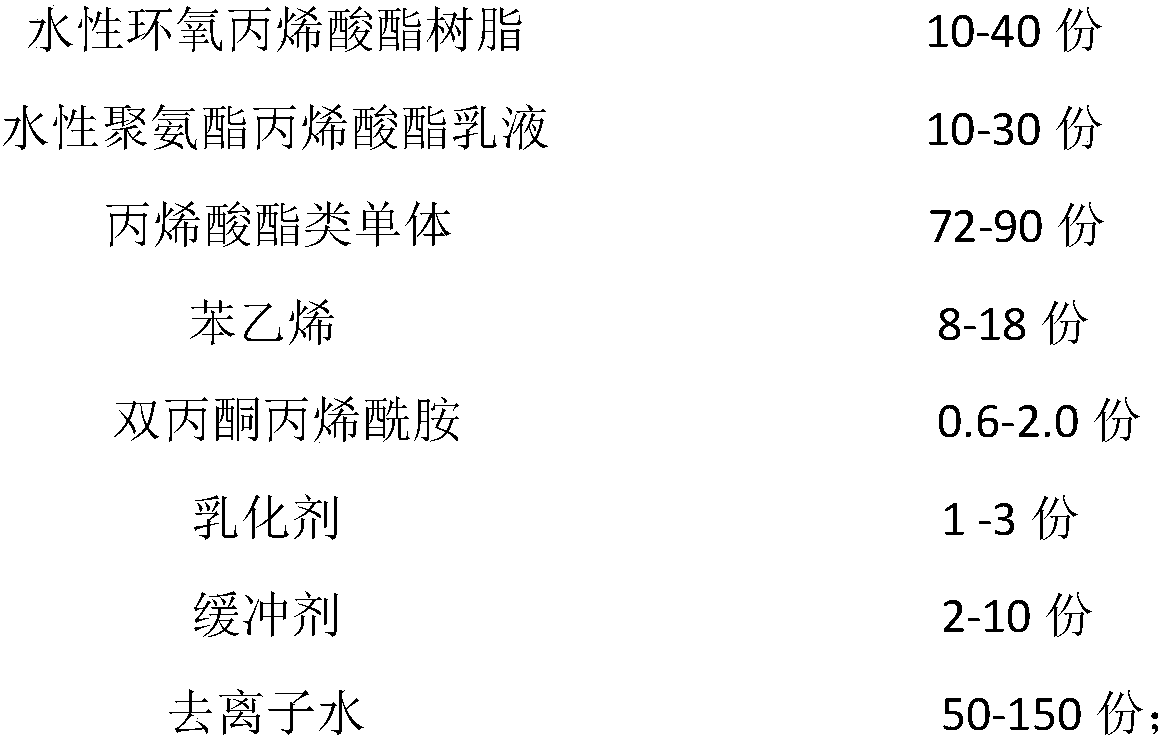

[0035] A pre-emulsion is prepared from the following raw materials in parts by mass:

[0036]

[0037]

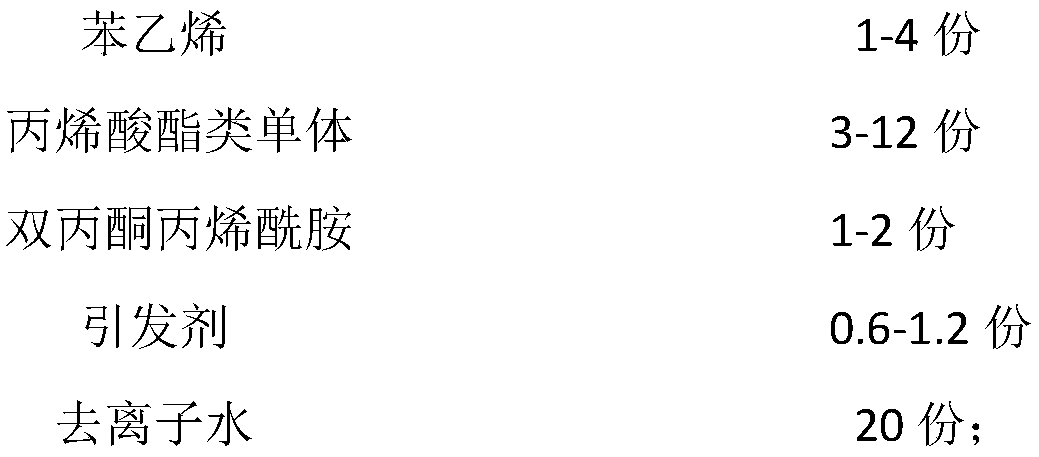

[0038] B emulsion is prepared from the raw materials of following mass parts:

[0039]

[0040] Solution C is prepared from the following raw materials in parts by mass:

[0041] Adipohydrazide 0.8 parts

[0042] 5 parts of deionized water.

[0043] The water-based epoxy acrylate is TJ157-70 water-based acrylic modified epoxy ester resin of Liangshan Tianjia Chemical Co., Ltd.

[0044] The water-based polyurethane acrylate emulsion is JAZO type water-based UV polyurethane acrylate of Nanjing Jiazhong Chemical Technology Co., Ltd.

[0045] The emulsifier is composed of sodium lauryl sulfate and nonylphenol polyoxyethylene ether, and the mass ratio of sodium lauryl sulfate and nonylphenol polyoxyethylene ether is 1:2.

[0046] The initiator is comp...

Embodiment 2

[0054] A water-based polysiloxane resin prepared from A pre-emulsion, B emulsion and C solution as raw materials:

[0055] A pre-emulsion is prepared from the following raw materials in parts by mass:

[0056]

[0057]

[0058]B emulsion is prepared from the raw materials of following mass parts:

[0059]

[0060] Solution C is prepared from the following raw materials in parts by mass:

[0061] Adipohydrazide 0.8 parts

[0062] 10 parts of deionized water.

[0063] The water-based epoxy acrylate is TJ153-70 water-based acrylic modified epoxy ester resin of Liangshan Tianjia Chemical Co., Ltd.

[0064] The water-based polyurethane acrylate emulsion is JAZO type water-based UV polyurethane acrylate of Nanjing Jiazhong Chemical Technology Co., Ltd.

[0065] The emulsifier is composed of sodium lauryl sulfate and nonylphenol polyoxyethylene ether, and the mass ratio of sodium lauryl sulfate and nonylphenol polyoxyethylene ether is 1:2.

[0066] The initiator is comp...

Embodiment 3

[0074] A water-based polysiloxane resin prepared from A pre-emulsion, B emulsion and C solution as raw materials:

[0075] A pre-emulsion is prepared from the following raw materials in parts by mass:

[0076]

[0077] B emulsion is prepared from the raw materials of following mass parts:

[0078]

[0079]

[0080] Solution C is prepared from the following raw materials in parts by mass:

[0081] Adipic hydrazide 1.5 parts

[0082] 10 parts of deionized water.

[0083] The water-based epoxy acrylate is TJ153-70 water-based acrylic modified epoxy ester resin of Liangshan Tianjia Chemical Co., Ltd.

[0084] The water-based polyurethane acrylate emulsion is JAZO type water-based UV polyurethane acrylate of Nanjing Jiazhong Chemical Technology Co., Ltd.

[0085] The emulsifier is composed of sodium lauryl sulfate and nonylphenol polyoxyethylene ether, and the mass ratio of sodium lauryl sulfate and nonylphenol polyoxyethylene ether is 1:2.

[0086] The initiator is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com