Patents

Literature

35results about How to "Excellent resistance to artificial aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly water-based nano anti-aging exterior wall coating

InactiveCN102827521AImprove abrasion resistanceStrong ability to resist wind and sand impactAntifouling/underwater paintsPaints with biocidesSodium aluminateDefoaming Agents

The invention relates to an environment-friendly water-based nano anti-aging exterior wall coating which comprises the components by weight percent: 15-30% of polyacrylic acid emulsion, 1-5% of film-forming additive, 0.1-0.3% of defoaming agent, 0.5-1% of dispersing agent, 0.1-0.5% of wetting agent, 2-5% of flatting agent, 1-6% of emulsifying agent, 15-25% of titanium dioxide, 2-5% of precipitated calcium carbonate, 0.5-3.5% of mica, 1-3% of zinc oxide, 3-7% of sodium silicoaluminate, 1.5-4.5% of talcum powder, 0.5-1% of thickening agent, 0.3-0.5% of mildew preventive, 10-30% of water, 2-5% of environment-friendly additive and 1-3% of water-based nano anti-aging agent. The environment-friendly water-based nano anti-aging exterior wall coating is good in scuff resistance, high in sandstorm impact resistance and even in coating without crack, can be used for blade coating, roller coating and spraying, has the functions of inhibiting bacteria, dispelling peculiar smell and cleaning air, and is remarkable in anti-man-made aging performance.

Owner:WUJIANG WUHUA HARDWARE PROD

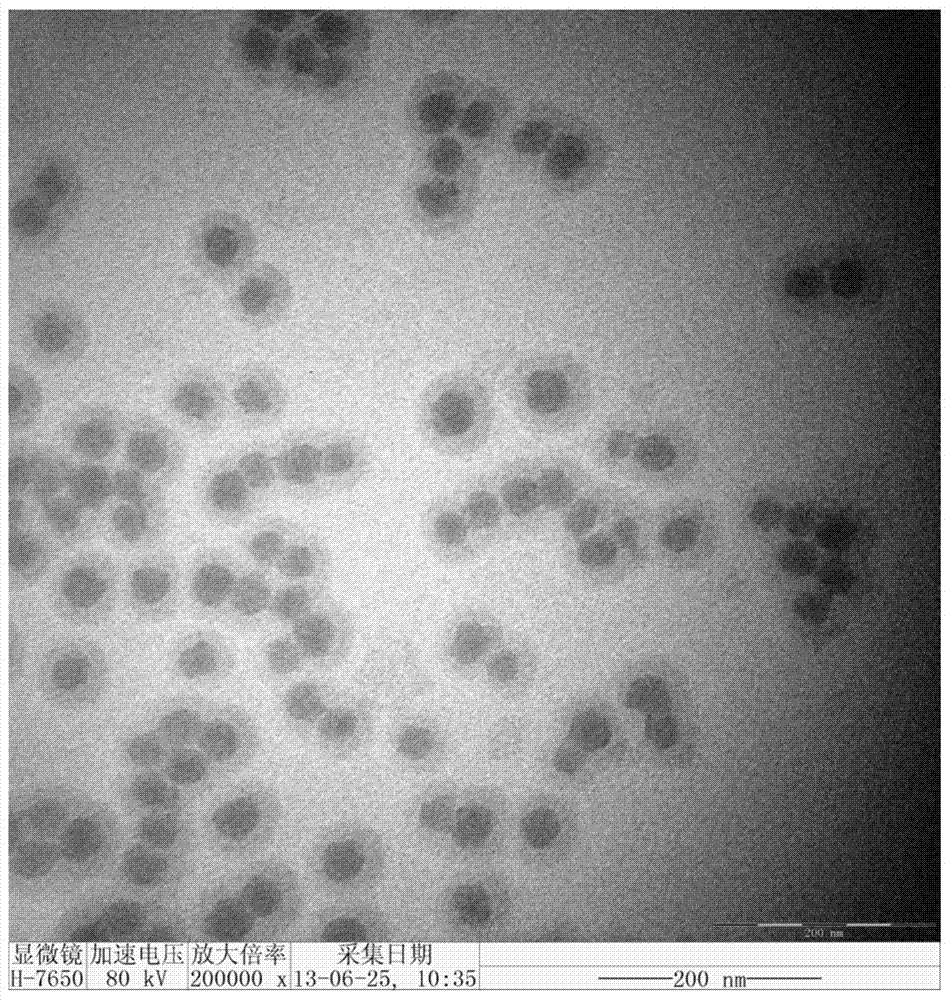

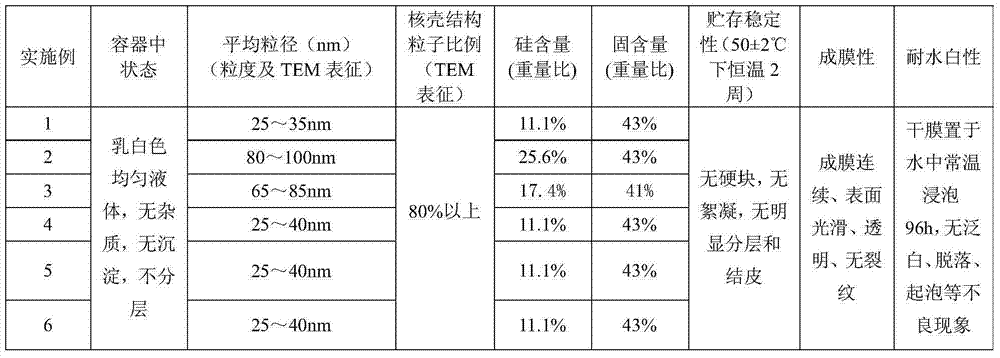

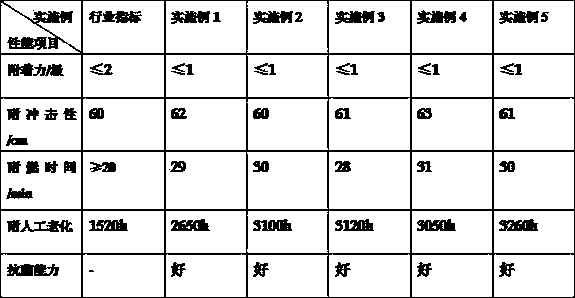

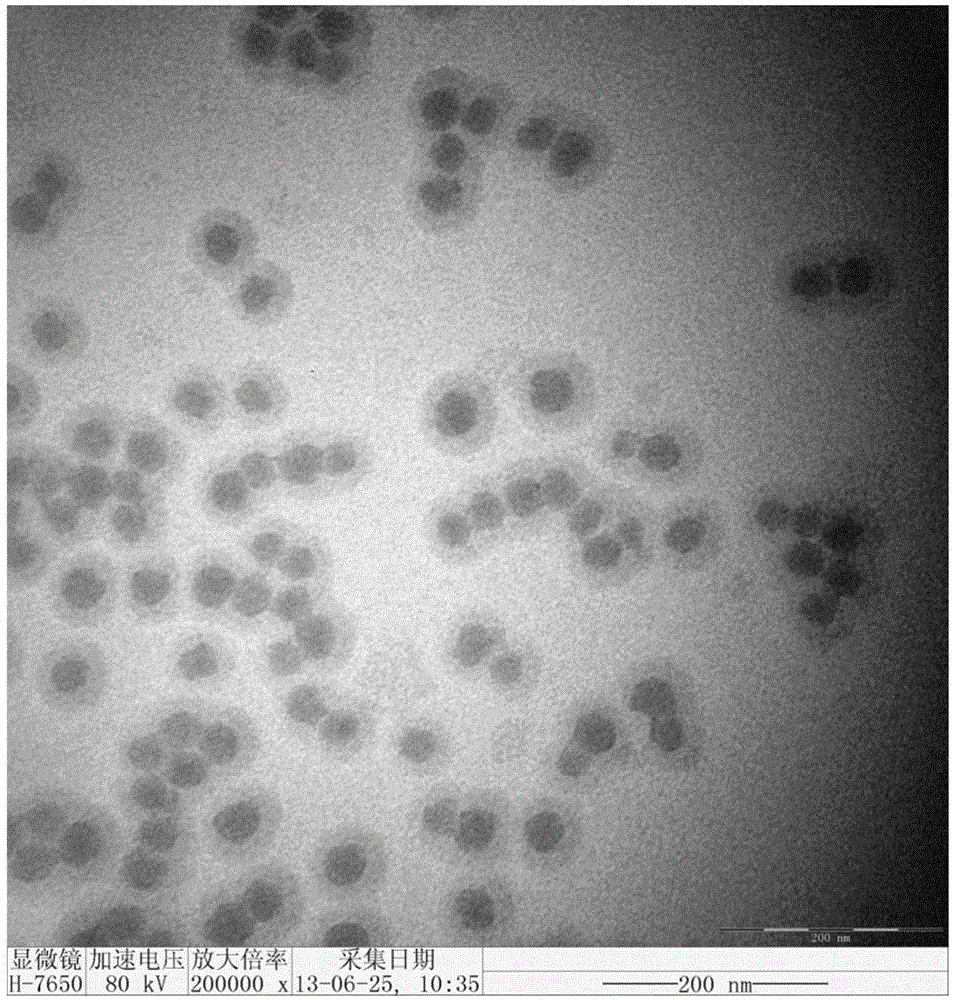

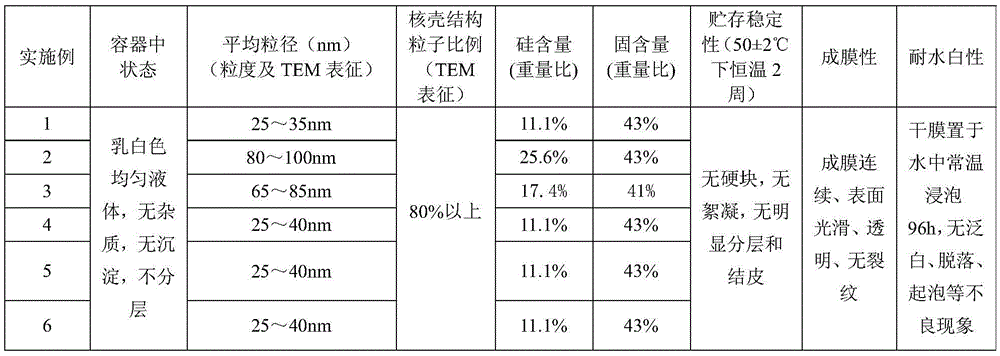

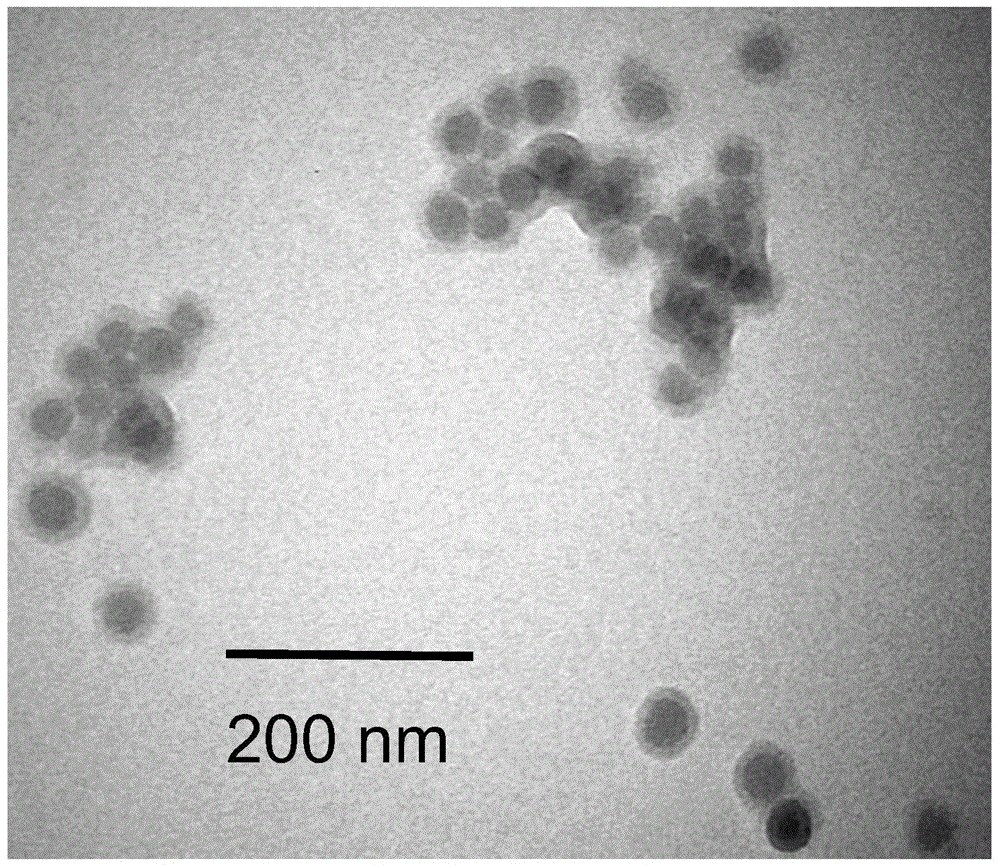

Unmodified silica sol/polyacrylate core-shell emulsion and preparation method thereof

ActiveCN104262531AFast Nano Core-Shell Composite StructureSmall particle sizePolymer scienceIn situ polymerization

The invention discloses a method for preparing an unmodified silica sol / polyacrylate core-shell emulsion. According to the method, commercially available alkaline silica sol and acrylate monomers are adopted as main raw materials, tedious surface modification treatment of nanoparticles is not needed, the monomers are subjected to in-situ polymerization on the surfaces of the unmodified SiO2 particles under the action of a reactive emulsifier so as to obtain a seed emulsion using SiO2 as cores and then acrylate shell polymerization is carried out on the surfaces of emulsifiable particles in the seed emulsion so as to synthesize the unmodified silica sol / polyacrylate core-shell emulsion with excellent performance. The method is simple in production process and the synthesis is rapid; the film of the synthesized unmodified silica sol / polyacrylate core-shell emulsion has the performances of high transparency, water resistance, high hardness, strong adhesion force as well as good stain resistance, heat resistance, acid and alkaline resistance, environmental friendliness, flame retardancy and the like and is high in performance and low in cost, is novel and environment friendly and can be widely applied in the field of multiple coatings.

Owner:GUANGXI UNIV

Nano fire-resistant paint, and preparation method and application thereof

InactiveCN104194504AQuality improvementEasy to useFireproof paintsAntifouling/underwater paintsPyrophosphateAnti bacteria

The invention discloses a nano fire-resistant paint which is composed of the following components in percentage by weight: 80-90% of component A and 10-20% of component B. The component A comprises the following components in parts by weight: 30-50 parts of ethylene-vinyl acetate copolymer, 20-25 parts of nano silicon dioxide, 1-8 parts of assistant and 0.4-0.6 part of mixed solvent. The assistant comprises a wetting agent, an anti-settling agent and a defoaming agent. The mixed solvent comprises propanediol and butyl acetate. The component B comprises the following components in parts by weight: 15-20 parts of cobalt naphthenate, 10-20 parts of melamine pyrophosphate, 20-30 parts of propanediol and 15-20 parts of talcum powder. The invention also discloses a preparation method and application of the fire-resistant paint. The nano fire-resistant paint has the advantages of stable quality, favorable use effect, higher adhesive force and more durable antimicrobial effect.

Owner:SUZHOU CHENGSHENG INFORMATION TECH

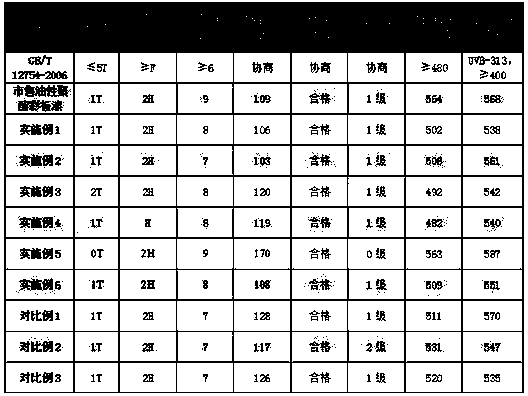

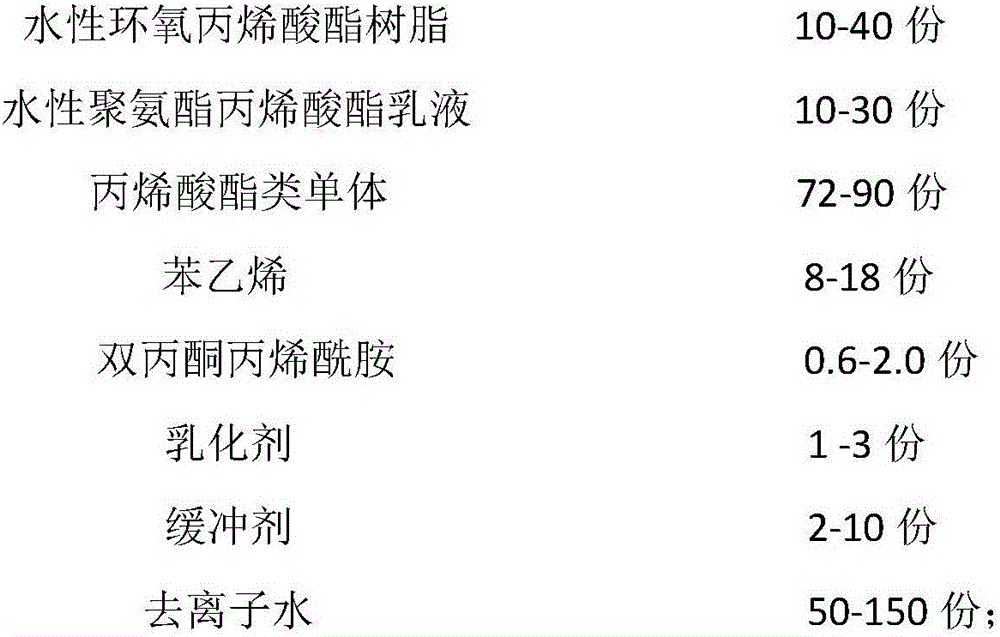

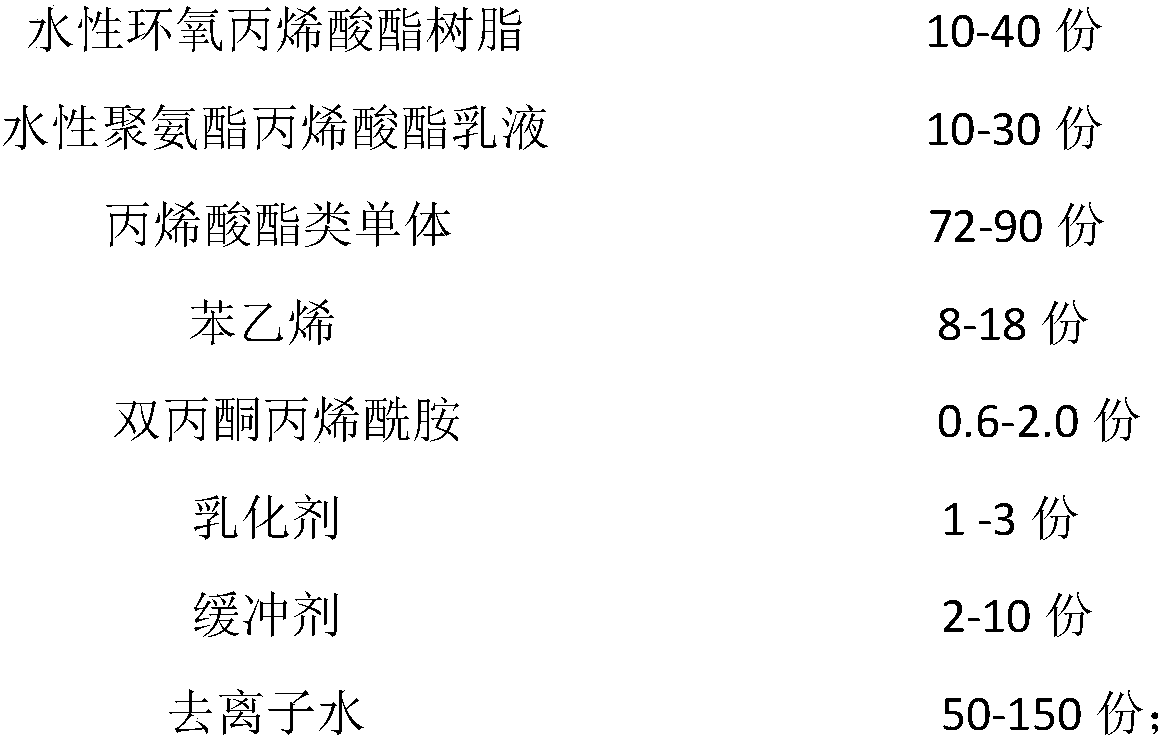

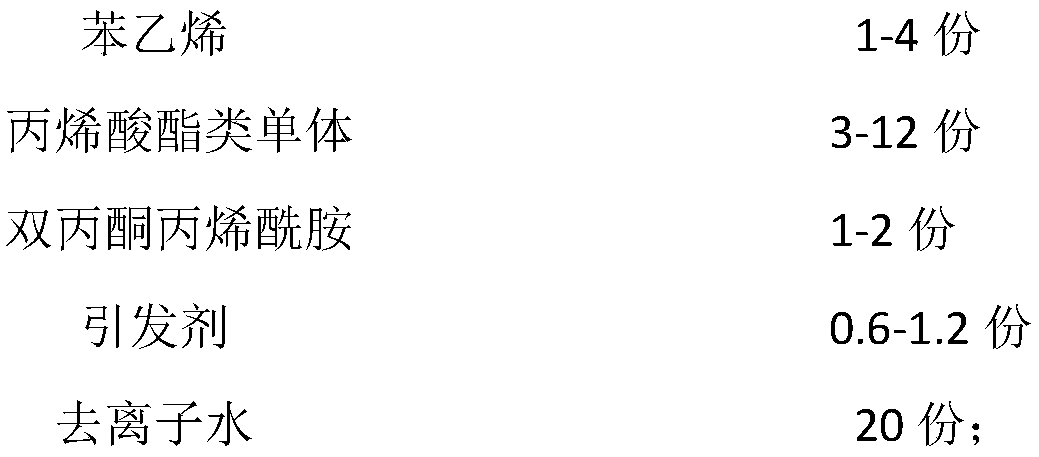

Aqueous modified acrylic emulsion as well as preparation method and application thereof

InactiveCN110627950AGood solvent resistanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesPropanoic acidPolymer science

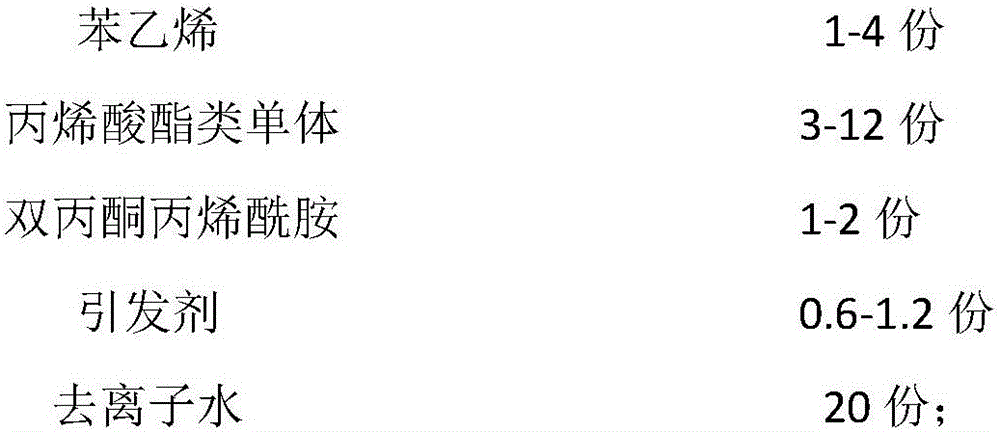

The invention belongs to the technical field of emulsions and in particular relates to an aqueous modified acrylic emulsion as well as a preparation method and application thereof. The aqueous modified acrylic emulsion comprises the following specific formulae: 56% of water, 1-2% of an emulsifier, 1-6% of a fluorine-containing monomer, 11-16% of butyl acrylate, 8-15% of methyl methacrylate, 3-11%of styrene, 0.25-0.5% of beta-acroloyl propionic acid, 0.25-0.5% of acrylic acid, 1-4% of hydroxyethyl acrylate, 0.5-3% of vinyl versatate, 0.3-0.8% of acrylamide, 1-2.5% of diacetone acrylamide (DAAM), 0.5-1.25% of adipic dihydrazide (ADH), 0.2-0.4% of persulfate and 0.6-1.5% of organic amine AMP-95. The emulsion provided by the invention is good in solvent resistance, weather resistance, stain resistance, artificial aging resistance and weather resistance, and in addition, excellent in scratch resistance, T bending resistance and impact properties.

Owner:淄博广栋化工有限公司

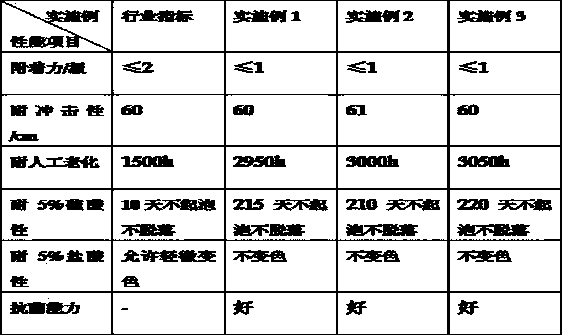

Self-flame-retardant oleth-2 phosphate modified water-based acrylic acid anticorrosive resin and preparation method thereof

ActiveCN110818828AGood flexibilityExcellent resistance to artificial agingFireproof paintsAnti-corrosive paintsEpoxyPhosphoric Acid Esters

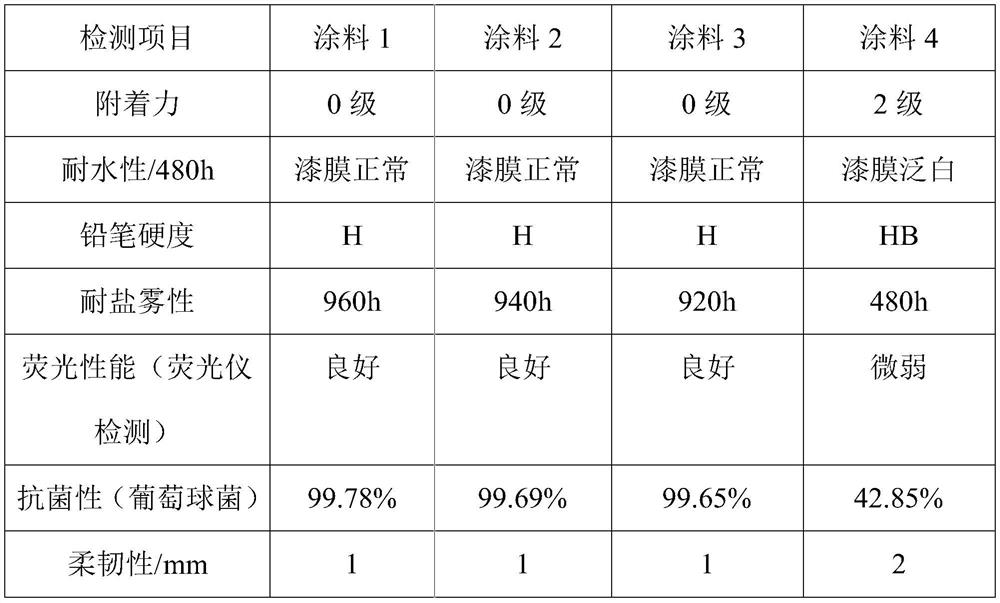

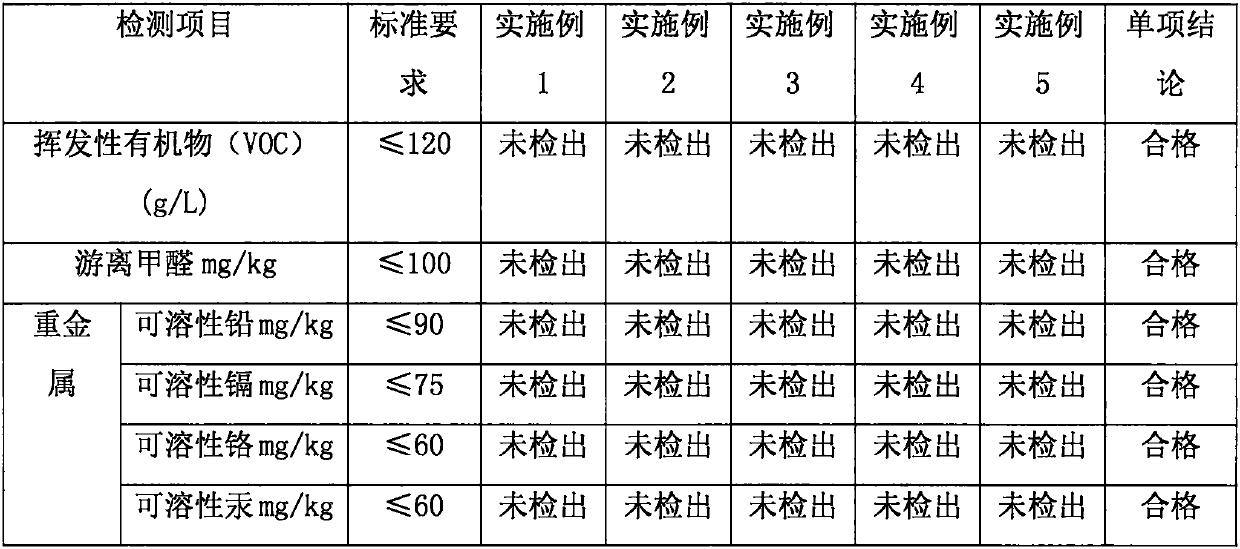

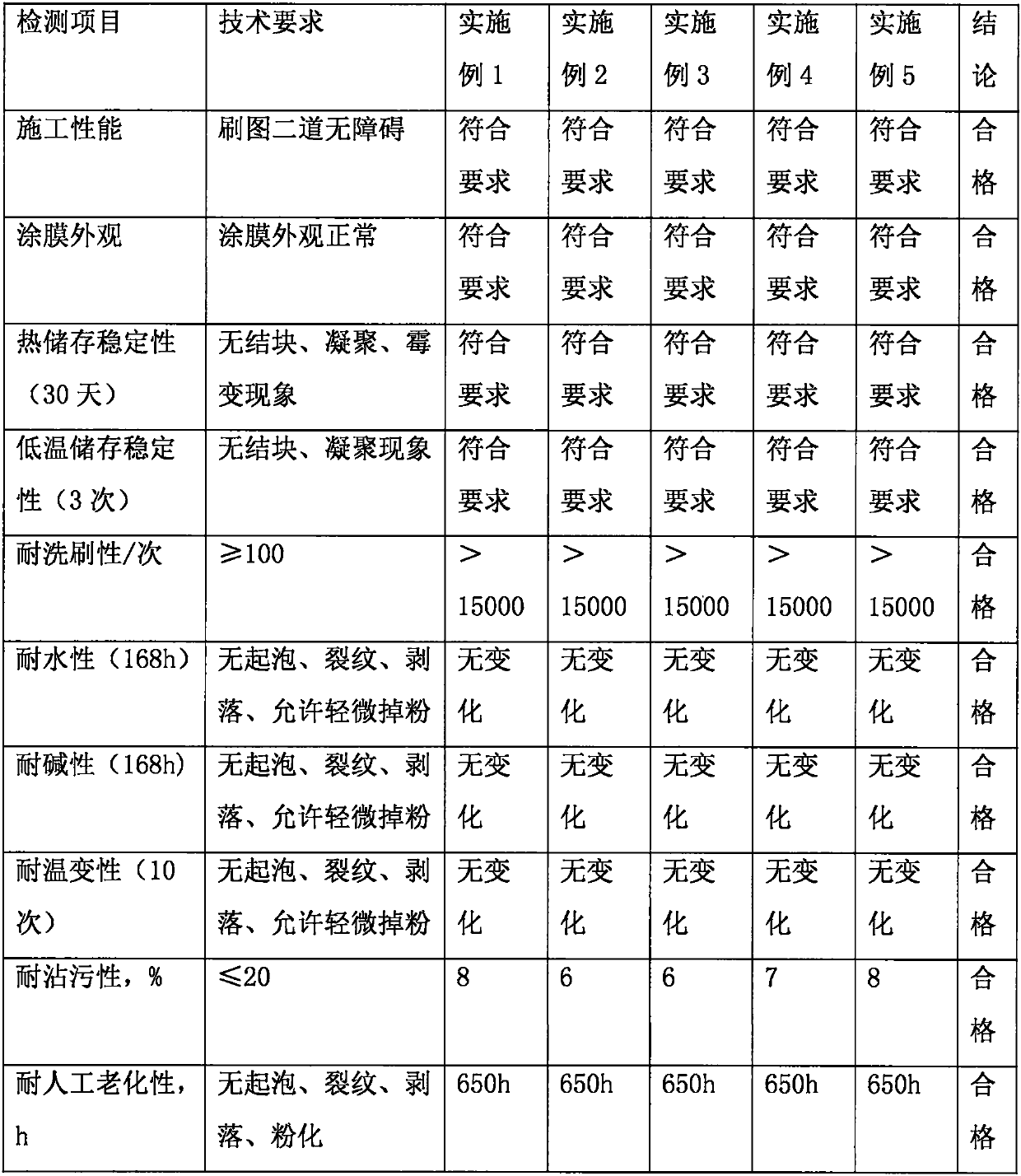

The invention relates to self-flame-retardant oleth-2 phosphate modified water-based acrylic acid anticorrosive resin and a preparation method thereof. The self-flame-retardant oleth-2 phosphate modified water-based acrylic acid anticorrosive resin comprises the following components by weight: 6.0-15.0 parts of oleth-2 phosphate, 5.0-5.0 9.0 parts of crosslinking monomers, 0.6 to 2.0 parts of benzoyl peroxide, 6.0-12.0 parts of propyl polyoxyethylene epoxy ether, 4.0-7.0 parts of acrylic acid, 65.0-130.0 parts of acrylate hard monomers, 10.0-30.0 parts of acrylate soft monomers, 2.0-5.0 partsof a silane coupling agent, 3.0-8.0 parts of allyl glycidyl ether, 30.0-50.0 parts of a cosolvent, 4.0-12.0 parts of a neutralizer and 100.0-200.0 parts of deionized water. The prepared self-flame-retardant oleth-2 phosphate modified water-based acrylic acid anticorrosive resin has a series of properties such as good flexibility, artificial aging resistance, acid and alkali resistance, salt fog resistance, corrosion resistance and flame retardance; and when the self-flame-retardant oleth-2 phosphate modified water-based acrylic acid anticorrosive resin is used for preparing a flame-retardant coating and an anticorrosive coating, an extra flame retardant and an extra anticorrosive agent are not needed, and single-component and double-component water-based coatings can be prepared.

Owner:UNION FOSHAN CHEM +1

High temperature resistant organic silicon resin emulsion paint

InactiveCN103360941AGuaranteed high temperature performanceStrong adhesionEpoxy resin coatingsEpoxyZinc phosphate

The invention discloses a high temperature resistant organic silicon resin emulsion paint comprising the following components in parts by weight: 25-40 parts of organic silicon resin, 10-15 parts of epoxy resin, 10-15 parts of coloring pigment, 1.8-2.5 parts of auxiliary, 28-35 parts of filler and 1.5-2.5 parts of zinc phosphate. Compared with the prior art, the high temperature resistant organic silicon resin emulsion paint has the advantages that the technical problems such as poor mechanical property, low adhesive force, wear resistance, artificial aging resistance and salt fog resistance and the like in the organic silicon paint are solved; the high temperature resistance is ensured, and meanwhile, the paint has excellent salt fog resistance, water resistance, artificial aging resistance, wear resistance and adhesive force; the requirements for modern motors, electrical appliances, space navigation and special medium resistance can be met.

Owner:南京市荣达树脂有限公司

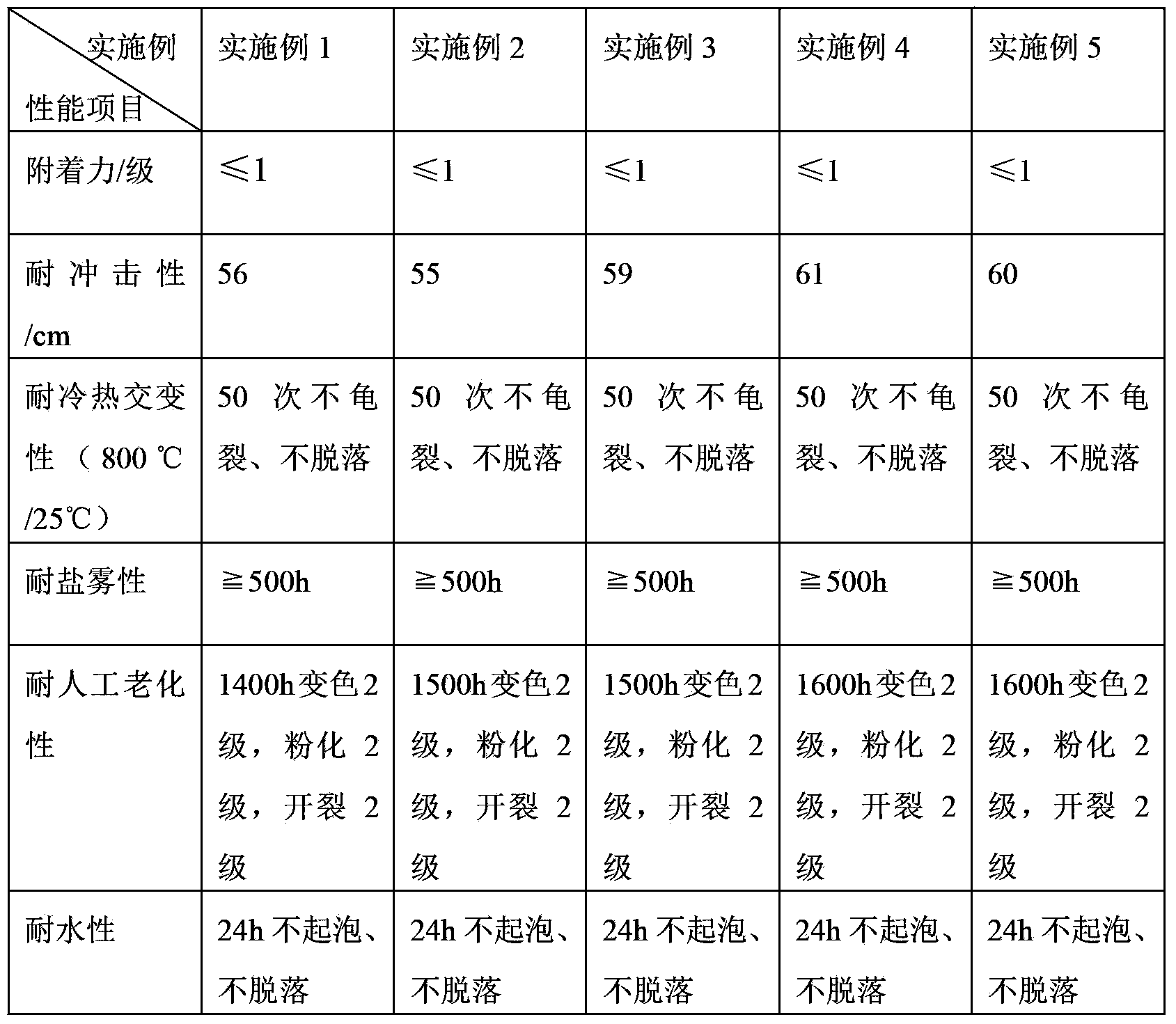

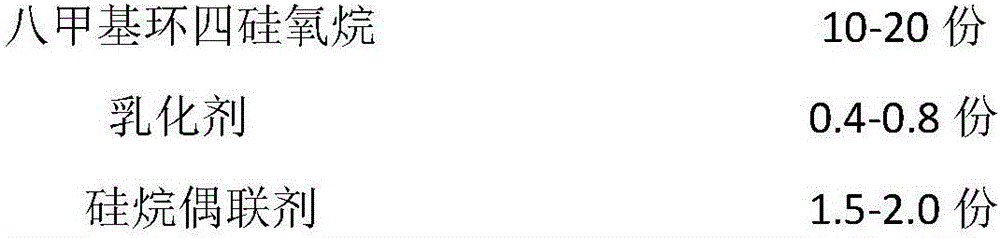

Aqueous polysiloxane resin and preparation method thereof

The invention discloses aqueous polysiloxane resin and a preparation method thereof. The aqueous polysiloxane resin is prepared from a pre-emulsion A, an emulsion B and a solution C as raw materials. The preparation method comprises the following steps: 1) preparing the pre-emulsion A; 2) preparing the emulsion B; 3) preparing the solution C; 4) pouring a part of the pre-emulsion A into a reaction container, dripping a part of the emulsion B, and at the same time heating the reaction container to 55-65 DEG C to react for 0.5-1 hour so as to prepare a light blue fluorescent seed emulsion; 5) simultaneously dripping the rest pre-emulsion A and the emulsion B into the fluorescent seed emulsion, heating to 55-65 DEG C to react for 2-3 hours, after the reaction is completed, cooling to the room temperature, adjusting the pH value to be 7-8, dripping the solution C, stirring for 10-30 minutes, and filtering, thereby obtaining a filtrate, that is, the aqueous polysiloxane resin. The aqueous polysiloxane resin is good in storage stability and flexibility, good in adhesion property, high in hardness and good in impact resistance, water resistance, salt water resistance, artificial aging resistance and chemical corrosion resistance. The aqueous polysiloxane resin is simple in preparation method, gentle in reaction condition and stable in process procedure.

Owner:WUHAN HOSTS COATING MATERIAL CO LTD

High molecular weight acrylic resin for polyvinylidene fluoride coiled material finish paint

ActiveCN102443098AHigh molecular weightOvercome the disadvantage that the molecular weight is not easy to increaseCoatings(Hydroxyethyl)methacrylateAcrylic resin

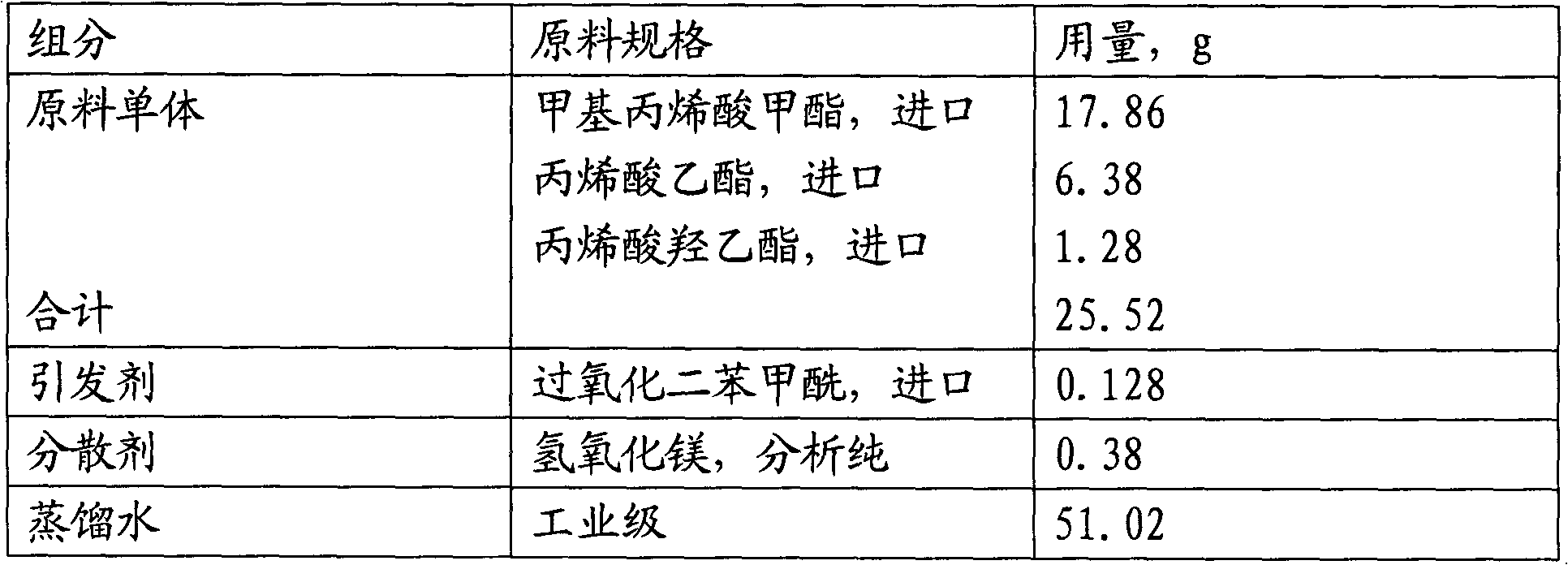

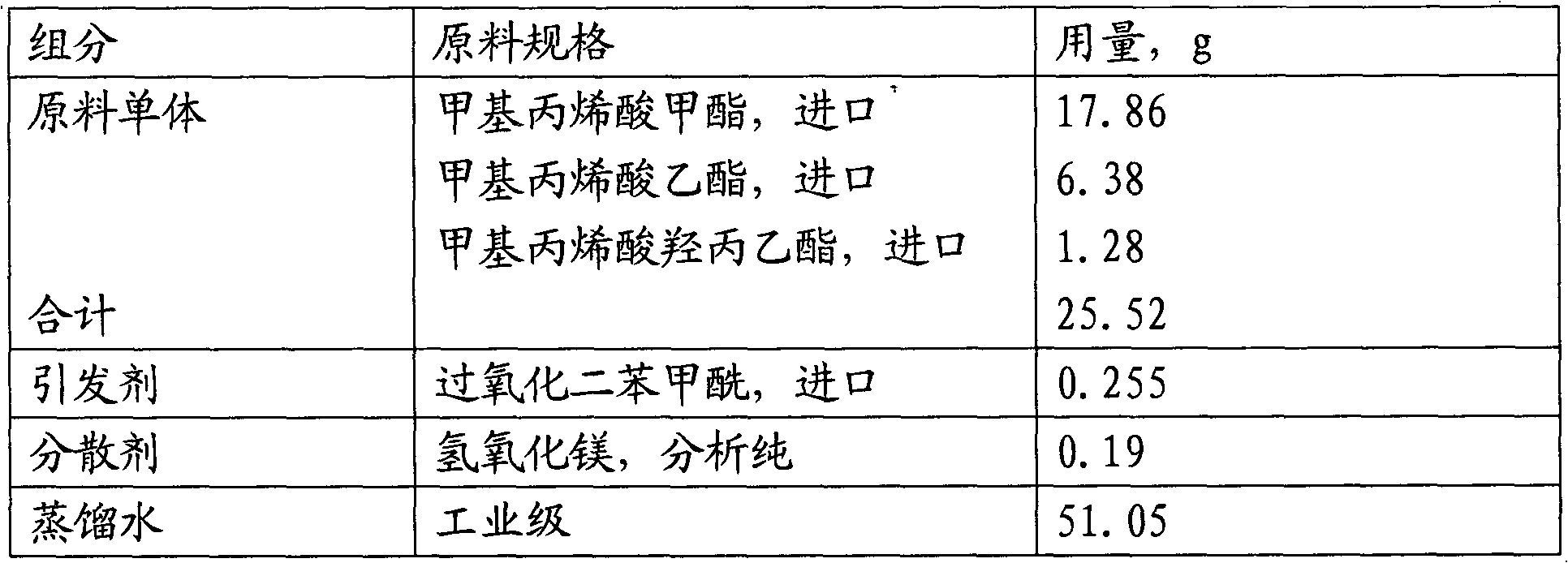

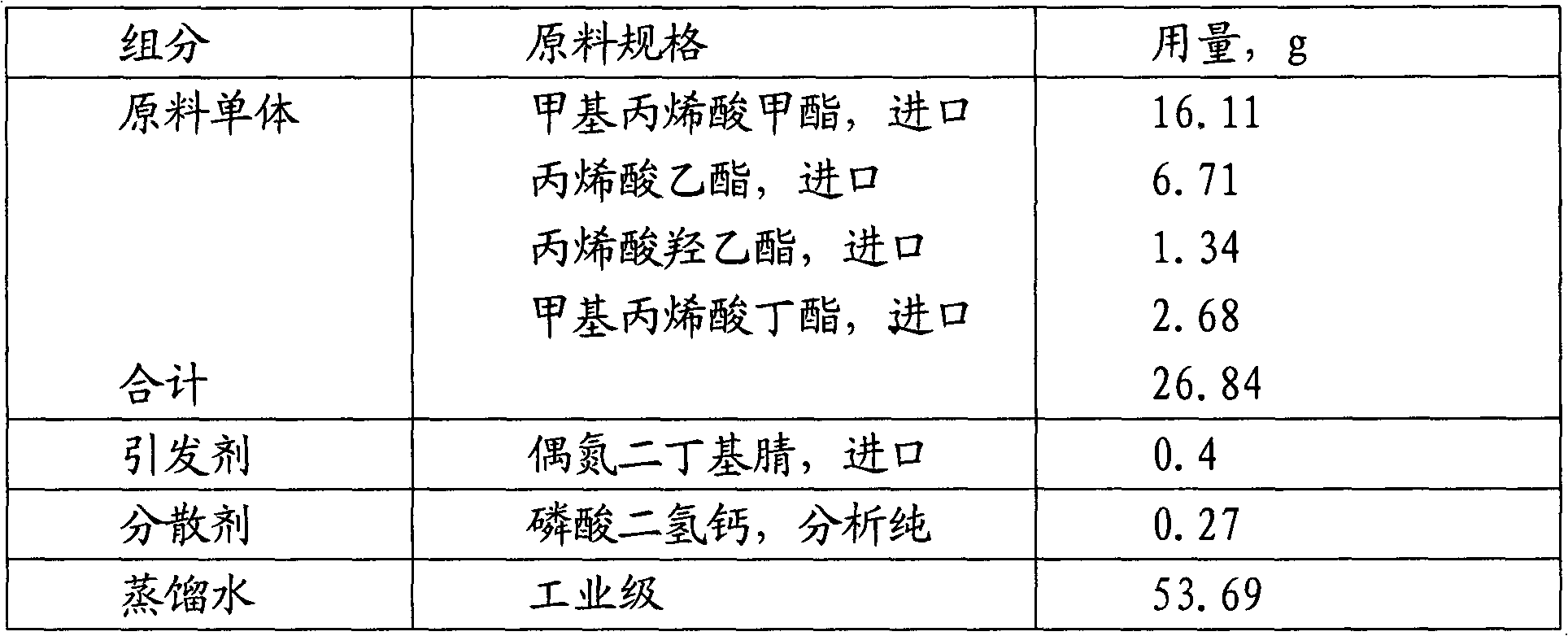

The invention relates to a high molecular weight acrylic resin for a polyvinylidene fluoride coiled material finish paint. The acrylic resin is combined with polyvinylidene fluoride resin as a coiled material finish paint base-material, is a bead-shape transparent particle and has a number-average molecular weight Mn higher than 90 thousand and molecular weight distribution Mw / Mn less than 2.0. The resin of the invention is prepared by a suspension polymerization method from material monomers of 50-80 wt% of methyl methacrylate and / or methyl acrylate, 10-40 wt% of ethyl acrylate and / or methyl methacrylate and 0-40 wt% of one or more selected from acrylic acid, hydroxyethyl acrylate, hydroxypropyl acrylate, methacrylic acid, hydroxyethyl methacrylate, hydroxypropyl methacrylate, butyl acrylate and butyl methacrylate. The high molecular weight acrylic resin of the invention can be combined with a PVDF resin, and a prepared finish paint film has comprehensive properties the same as an imported one and better performances on MEK-resistant wiping frequency and artificial ageing resistance.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Anti-mould corrosion-resistant flame-retardant polyethylene adhesive and preparation method thereof

InactiveCN104946140AImprove flame retardant performanceImprove abrasion resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCorrosion resistantAdhesive

The invention aims to provide an anti-mould corrosion-resistant flame-retardant polyethylene adhesive. The anti-mould corrosion-resistant flame-retardant polyethylene adhesive is characterized by comprising, by weight, 11-14 parts of diethyl terephthalate, 8-10 parts of methyl 3-aminocrotonat, 5-8 parts of tetrabromophthalic anhydride, 12-15 parts of polyethylene resin, 3-6 parts of inorganic silicate containing silver ions, 2-3 parts of aluminum hydroxide, 3-5 parts of zinc borate, 10-15 parts of polyvinyl alcohol, 10-15 parts of acrylate, 1-3 parts of catalyst, 1-3 parts of anti-mould agent, 10-15 parts of gelatin, 1-3 parts of curing agent, 10-15 parts of lignocellulose and 33-47 parts of deionized water. The anti-mould corrosion-resistant flame-retardant polyethylene adhesive has the advantages of being high in activity, high in stability, free of toxicity, low in cost and the like. The invention also provides an environment-friendly preparation method of the anti-mould corrosion-resistant flame-retardant polyethylene adhesive, scientific, reasonable, simple and easy to implement.

Owner:CHANGZHOU HUISEN ELECTRONICS

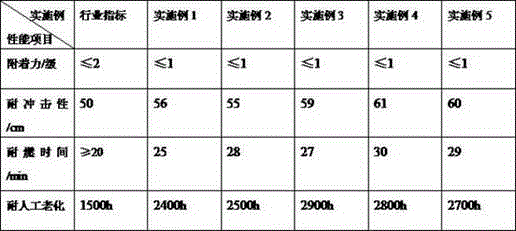

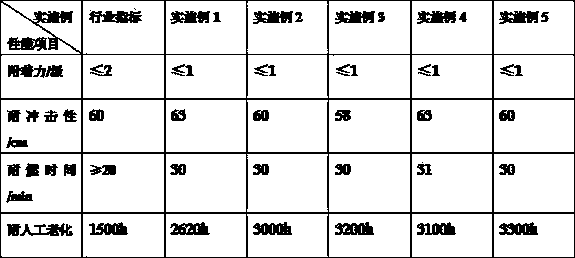

Tripolyindanone derivative modified water-based acrylic resin and preparation method thereof

InactiveCN112646084AHas antibacterial functionImprove stabilityAntifouling/underwater paintsLuminescent paintsPolymer scienceBenzoyl peroxide

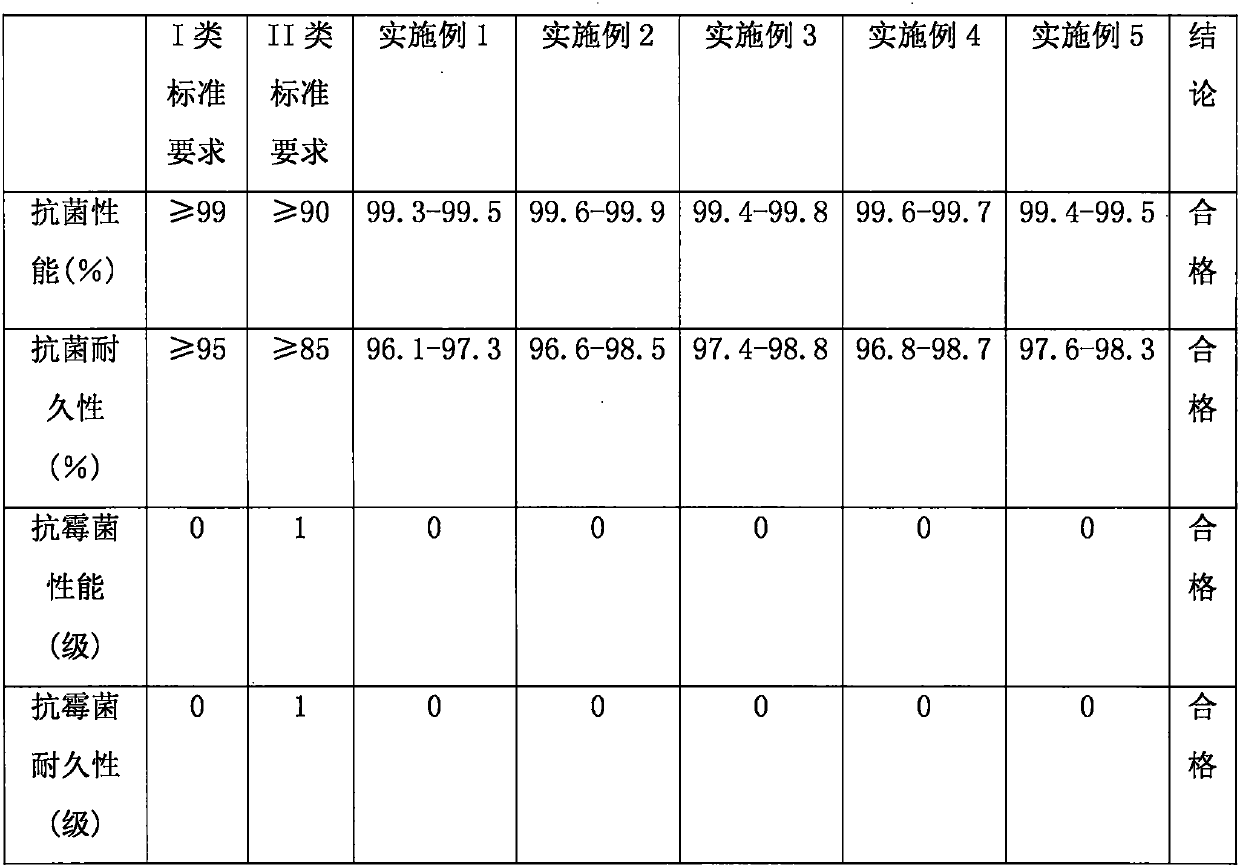

The invention relates to a tripolyindanone derivative modified water-based acrylic resin and a preparation method thereof. The resin is prepared from the following components in parts by weight: 1.5 to 4.5 parts of indanone derivative, 3.0 to 11.0 parts of isophorone diisocyanate, 0.5 to 1.2 parts of hydroxyethyl acrylate, 0.1 to 0.6 part of benzoyl peroxide, 2.0 to 5.0 parts of acrylic acid, 30.0 to 70.0 parts of acrylate hard monomer, 40.0 to 85.0 parts of acrylate soft monomer, 3.0 to 8.0 parts of allyl glycidyl ether, 12.0 to 35.0 parts of cosolvent, 5.0 to 10.0 parts of N-methylpyrrolidone, 1.8 to 7.5 parts of a neutralizer and 100.0 to 200.0 parts of deionized water. The prepared indanone derivative modified water-based acrylic resin has a series of functions of good artificial aging resistance, salt fog resistance, good fluorescence property and the like, and when the resin is prepared into water-based paint, an antibacterial agent does not need to be added, and the water-based paint has good antibacterial and bactericidal functions.

Owner:UNION FOSHAN CHEM +1

High-efficiency environment-friendly antibacterial mildew-proof paint containing nano film-forming agent and preparation method thereof

PendingCN111362641AImprove adhesionIncrease surface areaCeramicwareSodium BentonitePolyvinyl alcohol

The invention provides a high-efficiency environment-friendly antibacterial mildew-proof paint containing a nano film-forming agent and a preparation method thereof. The paint is prepared from the following raw materials: heavy calcium powder, ash calcium powder, white Portland cement, hollow microspheres, nano silicon dioxide, rutile titanium dioxide, dicalcium silicate, sepiolite powder, sodiumoxalate, talcum powder, tourmaline powder, attapulgite clay, sodium bentonite, polyvinyl alcohol powder, redispersible latex powder, lithium sulfate, calcium lignosulphonate, hydroxypropyl methyl cellulose, wood fibers and an organic silicon polyether composite defoaming agent. The prepared interior and exterior wall dry powder paint is suitable for interior and exterior walls, is non-toxic and environment-friendly, does not pollute the environment, does not influence body health, has excellent antibacterial and anti-mildew construction performance and other properties, is long in service life, is a dry powder coating, is simple in production process, and has the advantages of being convenient to transport, long in storage period and the like.

Owner:刘飞跃

Broad-spectrum heat isolating and insulating coating compound and preparation method thereof

InactiveCN101864234BReduce absorptionReduce transmissionReflecting/signal paintsIr reflectionComposite ceramic

Owner:CHONGQING LONGZHE HIGH TECH MATERIAL

Anti-aging putty

InactiveCN104559411AEffective antibacterial and odor removalImprove abrasion resistanceFilling pastesFiberParaffin wax

The invention relates to anti-aging putty which comprises components as follows: 10 parts of white cement, 15 parts of calcium bicarbonate, 8 parts of heavy calcium carbonate powder, 6 parts of ash calcium powder I, 8 parts of talc powder, 5 parts of ash calcium powder II, 2 parts of ferric sodium pyrophosphate, 1 part of ferric phosphate, 5 parts of calcite, 5 parts of fluorite, 12 parts of quartz powder, 1 part of propylamine, 2 parts of HPMC (hydroxypropyl methyl cellulose), 2 parts of wood fibers, 1 part of rubber powder, 2 parts of magnesium chloride and 2 parts of paraffin. The putty can effectively inhibit bacteria, remove peculiar smells and purify air and is good in rub resistance, high in wind sand impact resistance and particularly significant in artificial aging resistance, and coatings are uniform and free of cracks, scrape coating, roll coating and spray costing can be performed.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

A kind of aqueous polysiloxane resin and preparation method thereof

The invention discloses aqueous polysiloxane resin and a preparation method thereof. The aqueous polysiloxane resin is prepared from a pre-emulsion A, an emulsion B and a solution C as raw materials. The preparation method comprises the following steps: 1) preparing the pre-emulsion A; 2) preparing the emulsion B; 3) preparing the solution C; 4) pouring a part of the pre-emulsion A into a reaction container, dripping a part of the emulsion B, and at the same time heating the reaction container to 55-65 DEG C to react for 0.5-1 hour so as to prepare a light blue fluorescent seed emulsion; 5) simultaneously dripping the rest pre-emulsion A and the emulsion B into the fluorescent seed emulsion, heating to 55-65 DEG C to react for 2-3 hours, after the reaction is completed, cooling to the room temperature, adjusting the pH value to be 7-8, dripping the solution C, stirring for 10-30 minutes, and filtering, thereby obtaining a filtrate, that is, the aqueous polysiloxane resin. The aqueous polysiloxane resin is good in storage stability and flexibility, good in adhesion property, high in hardness and good in impact resistance, water resistance, salt water resistance, artificial aging resistance and chemical corrosion resistance. The aqueous polysiloxane resin is simple in preparation method, gentle in reaction condition and stable in process procedure.

Owner:WUHAN HOSTS COATING MATERIAL CO LTD

Water-based dyed mortar material and preparation method thereof

The invention discloses a water-based dyeing mortar material and a preparation method thereof in the technical field of coating preparation, the water-based dyeing mortar material comprises the following components in parts by weight: 60-80 parts of emulsion, 0.2-0.5 part of a dispersing wetting agent, 5-10 parts of a film forming auxiliary agent, 2-5 parts of other auxiliary agents, 1-1.5 parts of a pH regulator, 1-1.5 parts of toner and 10-20 parts of deionized water, has excellent color fastness, mechanical strength, water resistance, boiling water resistance, acid and alkali resistance, solvent resistance, natural aging resistance, artificial aging resistance and other outstanding performances, has environmentally-friendliness, zero VOC, no production of industrial three wastes, no color restriction, optional color mixing, convenient production, simple color mixing process, low equipment requirements, low cost, water as a solvent, low cost of raw materials, natural drying, and no energy consumption, and can be used for building interior and exterior wall paint, permeable bricks, artificial stone, integrated boards and handicrafts.

Owner:郑州科威科建筑材料有限公司

Multicolored heat-insulation and heat-preservation coating material and preparation method therefor

InactiveCN105482566AQuality improvementEasy to useFireproof paintsMulticolor effect coatingsXylyleneAcetic acid

The invention discloses a multicolored heat-insulation and heat-preservation coating material. The multicolored heat-insulation and heat-preservation coating material contains the following ingredients in percentage by weight: 80-90% of ingredient A and 10-20% of ingredient B; the ingredient A contains the following ingredients in parts by weight: 40-50 parts of high chlorinated polyethylene, 15-18 parts of coloring pigment, 2-5 parts of adjuvants and 0.1-0.5 part of mixed solvent, wherein the adjuvants comprise a plasticizer, an anti-settling agent and a thixotropic agent, and the mixed solvent comprises xylene and butyl acetate; and the ingredient B contains the following ingredients in parts by weight: 10-15 parts of ammonium polyphosphate, 12-18 parts of melamine, 15-20 parts of pentaerythritol and 10-15 parts of talcum powder. The fireproof coating material provided by the invention is stable in quality and good in use effect and has good impact resistance and artificial aging resistance and relatively high adhesive power while having an excellent fireproof effect.

Owner:NANJING CHANGJIANG PAINT

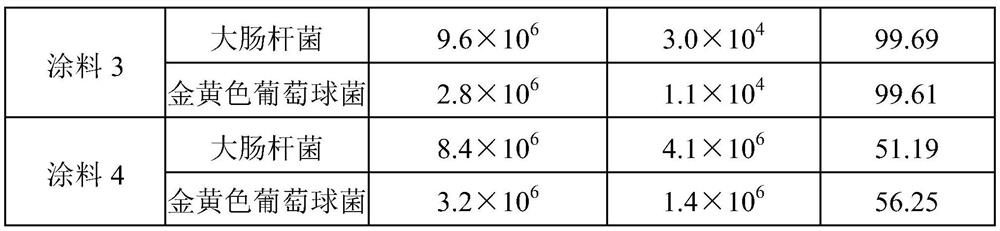

Triptycene derivative modified waterborne acrylic resin and preparation method thereof

InactiveCN112625170AImprove the bactericidal effectImprove performanceAntifouling/underwater paintsPaints with biocidesMethacrylatePolymer science

The invention relates to triptycene derivative modified water-based acrylic resin and a preparation method of the triptycene derivative modified water-based acrylic resin. The resin comprises the following components in parts by weight: 2.0 to 6.0 parts of triptycene derivative, 1.0 to 4.0 parts of crosslinking monomer, 0.2 to 0.8 part of benzoyl peroxide, 2.0 to 8.0 parts of trimethylolpropane trimethacrylate, 2.0 to 5.0 parts of acrylic acid, 10.0 to 30.0 parts of acrylate hard monomer, 15.0 to 45.0 parts of acrylate soft monomer, 1.0 to 4.0 parts of vinyl trimethoxy silane, 10.0 to 25.0 parts of cosolvent, 1.5 to 4.5 parts of neutralizer and 50.0 to 120.0 parts of deionized water. The triptycene derivative modified waterborne acrylic resin prepared by the invention has a series of properties such as good artificial aging resistance, acid and alkali resistance, salt fog resistance, corrosion resistance, water resistance, adsorbability, bacteria resistance, sterilization and the like, and a bactericide does not need to be added when the triptycene derivative modified waterborne acrylic resin is made into a coating. The waterborne acrylic resin can be made into single-component and double-component water-based paint.

Owner:UNION FOSHAN CHEM +1

Nanometer anticorrosion coating and preparation method thereof

InactiveCN104212262AQuality improvementEasy to useAntifouling/underwater paintsPaints with biocidesEthyl groupMelamine formaldehyde resin

The invention discloses a nanometer anticorrosion coating. The anticorrosion coating comprises the following components in percentage by weight: 80-90% of a component A and 10-20% of a component B, wherein the component A comprises the following components in parts by weight: 30-50 parts of a styrene-butadiene polymer, 20-25 parts of nanometer silicon oxide, 1-8 parts of an additive and 0.4-0.6 part of a mixed solvent, wherein the additive comprises a defoaming agent, a flattening agent and a dispersing agent; the mixed solvent comprises 1,4-butanediol and trimethylol ethane; the component B comprises the following components in parts by weight: 15-20 parts of N-(2-mercaptoethyl) pivaloyl, 10-20 parts of melamine-formaldehyde resin, 20-30 parts of butyl glycol and15-20 parts of talc powder. The invention also discloses a preparation method of the nanometer anticorrosion coating. The nanometer anticorrosion coating disclosed by the invention has the advantages of stable quality, excellent corrosion resistance and more lasting antibacterial effect and has good market prospects.

Owner:SUZHOU CHENGSHENG INFORMATION TECH

Fireproof coating and preparation method thereof

InactiveCN104194505AQuality improvementEasy to useFireproof paintsPhosphoric Acid EstersPolymer science

The invention discloses a fireproof coating, comprising the following components in percentage by weight: 80-90% of component A and 10-20% of component B, wherein the component A comprises the following components in parts by weight: 30-50 parts of an ethylene-vinyl acetate copolymer, 20-25 parts of a tinting pigment, 1-8 parts of an assistant and 0.4-0.6 part of a mixed solvent; the assistant comprises a wetting agent, an anti-settling agent and a defoaming agent; the mixed solvent comprises propylene glycol and butyl acetate; the component B comprises the following components in parts by weight: 15-20 parts of cobalt naphthenate, 10-20 parts of melamine pyrophosphate, 20-30 parts of propylene glycol and 15-20 parts of talcum powder. The invention also discloses a preparation method of the fireproof coating. The fireproof coating disclosed by the invention is stable in quality, and good in using effect, and simultaneously has good impact resistance, good artificial ageing resistance and strong adhesive force when having an excellent fireproof effect.

Owner:SUZHOU CHENGSHENG INFORMATION TECH

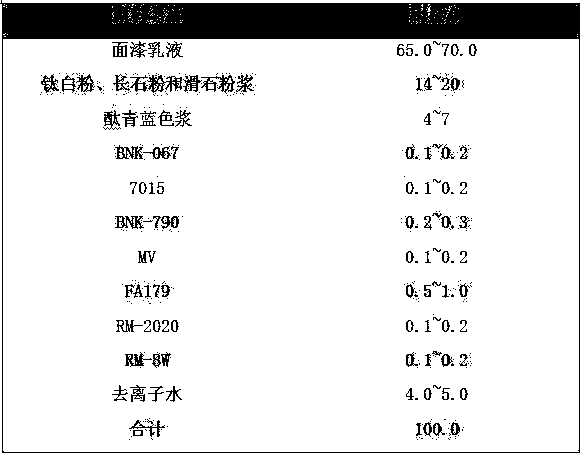

A kind of antifouling nano exterior wall paint and preparation method thereof

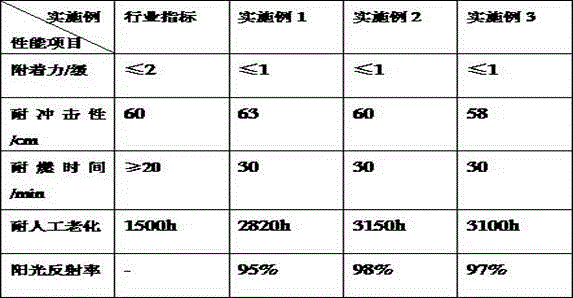

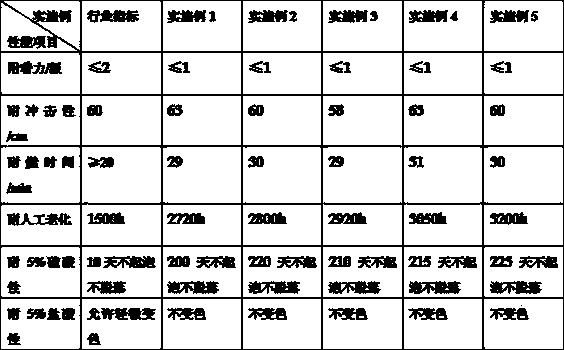

InactiveCN103614042BSmall particle sizeReduce resource usageAntifouling/underwater paintsPaints with biocidesPerformance indexRutile

The invention discloses an antifouling nano exterior wall coating and a preparation method thereof. The antifouling nano exterior wall coating is composed of the following components: 10-20% of water, 15-30% of rutile titanium dioxide, 0-15% of wollastonite powder, 0-5% of calcined kaolin, 30-60% of nano core-shell composite emulsion, 1-5% of coalescing agent, 0.5-2% of anti-freezing agent and 2.2-5.8% of small-dosage additive. The antifouling nano exterior wall coating and the preparation method thereof disclosed by the invention have the advantages that: 1. inorganic nano particles in the coating disclosed by the invention replace a part of polymers, thereby greatly reducing the use of organic oil resources, lowering the cost and improving the comprehensive performance of the coating; and 2. various performance indexes of the coating disclosed by the invention can meet the requirements of national standard GB / T9755-2001 superior products, the coating especially has excellent water resistance, alkali resistance, stain resistance and artificial aging resistance, and the wash resistance frequency of the coating is more than 10000.

Owner:GUANGXI UNIV +1

A self-blocking fuel alcohol polyether-2 phosphate modified water-based acrylic anticorrosion resin and its preparation method

ActiveCN110818828BGood flexibilityExcellent resistance to artificial agingFireproof paintsAnti-corrosive paintsPhosphoric Acid EstersEpoxy

The invention relates to a self-blocking oil polyether-2 phosphate modified water-based acrylic anticorrosion resin and a preparation method thereof. In parts by weight, the components are: 6.0-15.0 parts of oleyl polyether-2 phosphate, 5.0-9.0 parts of crosslinking monomer, 0.6-2.0 parts of benzoyl peroxide, 6.0-12.0 parts of propyl polyoxyethylene epoxy ether, 4.0-7.0 parts of acrylic acid, 65.0-130.0 parts of acrylate hard monomer, acrylic acid 10.0-30.0 parts of ester soft monomer, 2.0-5.0 parts of silane coupling agent, 3.0-8.0 parts of allyl glycidyl ether, 30.0-50.0 parts of co-solvent, 4.0-12.0 parts of neutralizing agent, 100.0-200.0 parts of deionized water part; the self-blocking fuel alcohol polyether-2 phosphate modified water-based acrylic anticorrosion resin prepared by the present invention has good flexibility, artificial aging resistance, acid and alkali resistance, salt spray resistance, corrosion resistance, A series of properties such as flame retardancy, when preparing flame-retardant coatings and anti-corrosion coatings, no additional flame retardants and anti-corrosion agents are required; it can be formulated into one-component and two-component water-based coatings.

Owner:UNION FOSHAN CHEM +1

Tripolyindanone derivative modified acrylic resin water-based paint

InactiveCN112662262AGood stabilityExcellent resistance to artificial agingAntifouling/underwater paintsLuminescent paintsPolymer chemistryPerylene derivatives

The invention relates to a tripolyindanone derivative modified acrylic resin water-based paint which is composed of the following components in parts by weight: 100.0-150.0 parts of tripolyindanone derivative modified water-based acrylic resin, 20.0-40.0 parts of fluorine modified water-based acrylic resin, 0.6-2.4 parts of assistant, 3.0-6.0 parts of diatomite, 3.0-10.0 parts of nano silicon dioxide, 2.0-35.0 parts of pigment filler and 15.0-50.0 parts of deionized water. According to the tripolyindanone derivative modified acrylic resin water-based paint prepared by the preparation method disclosed by the invention, a coalescing agent does not need to be added, and a good film-forming property is realized; an antibacterial agent does not need to be added, and a good antibacterial function is achieved; light-emitting filler does not need to be additionally added, and good light-emitting performance is achieved; and due to the surface tension of the paint, the surface of the paint is difficultly covered by pollutants, and the performance is durable and stable.

Owner:UNION FOSHAN CHEM +1

A kind of anti-ultraviolet fireproof coating and preparation method thereof

The invention discloses an anti-ultraviolet fireproof coating, the components of which are composed of the following components by weight percentage: 80-90% of A component and 10-20% of B component; the A component includes by weight The following components: 30-50 parts of vinyl resin, 20-25 parts of coloring pigment, 1-8 parts of auxiliary agent, 0.4-0.6 part of mixed solvent; the auxiliary agent includes anti-ultraviolet auxiliary agent, anti-settling agent and defoamer ; The mixed solvent includes ethyl acetate and dimethyldiethoxysilane; the B component includes the following components in parts by weight: 15~20 parts of cobalt naphthenate, 10~20 parts of melamine pyrophosphate , 20~30 parts of propylene glycol, 15~20 parts of talcum powder. The invention also discloses a preparation method of the above-mentioned anti-ultraviolet fireproof paint. The anti-ultraviolet fireproof paint provided by the invention is stable in quality, has excellent fireproof effect and anti-ultraviolet effect at the same time.

Owner:苏州圣典企业管理咨询有限公司 +1

Fireproof corrosion-preventing coating and preparation method thereof

InactiveCN104212261AQuality improvementEasy to useFireproof paintsAnti-corrosive paintsEthyl groupMelamine formaldehyde resin

The invention discloses a fireproof corrosion-preventing coating which is prepared from the following components in percentage by weight: 80-90% of a component A and 10-20% of a component B, wherein the component A comprises the following components in parts by weight: 30-50 parts of a styrene-butadiene polymer, 20-25 parts of a coloring pigment, 1-8 parts of an auxiliary and 0.4-0.6 part of a mixed solvent; the auxiliary comprises a flame retardant, a thickener and a disperser; the mixed solvent comprises 1, 4-butanediol and trimethylol ethane; the component B comprises the following components in parts by weight: 15-20 parts of N-(2-sulfydryl ethyl) valeryl, 10-20 parts of tripolycyanamide-formaldehyde resin, 20-30 parts of butyl glycol and 15-20 parts of talcum powder. The invention further discloses a preparation method of the fireproof corrosion-preventing coating. The fireproof corrosion-preventing coating disclosed by the invention is stable in quality and good in using effect and has both a good corrosion-resisting performance and an excellent fireproof effect.

Owner:SUZHOU CHENGSHENG INFORMATION TECH

Unmodified silica sol/polyacrylate core-shell emulsion and preparation method thereof

ActiveCN104262531BFast Nano Core-Shell Composite StructureSmall particle sizeEmulsionIn situ polymerization

Owner:GUANGXI UNIV

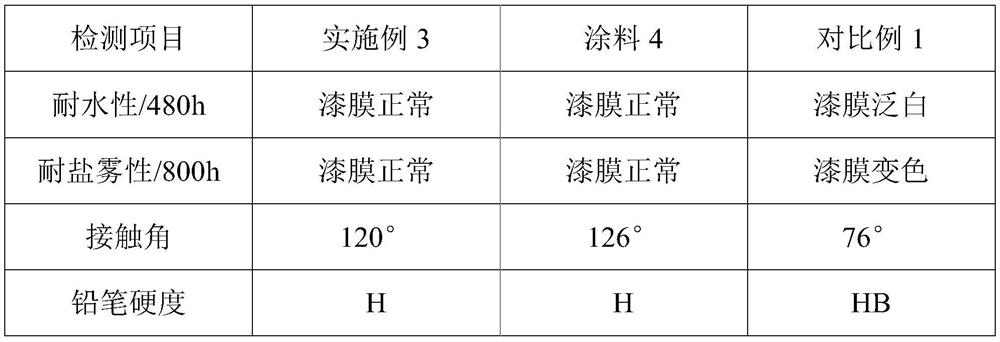

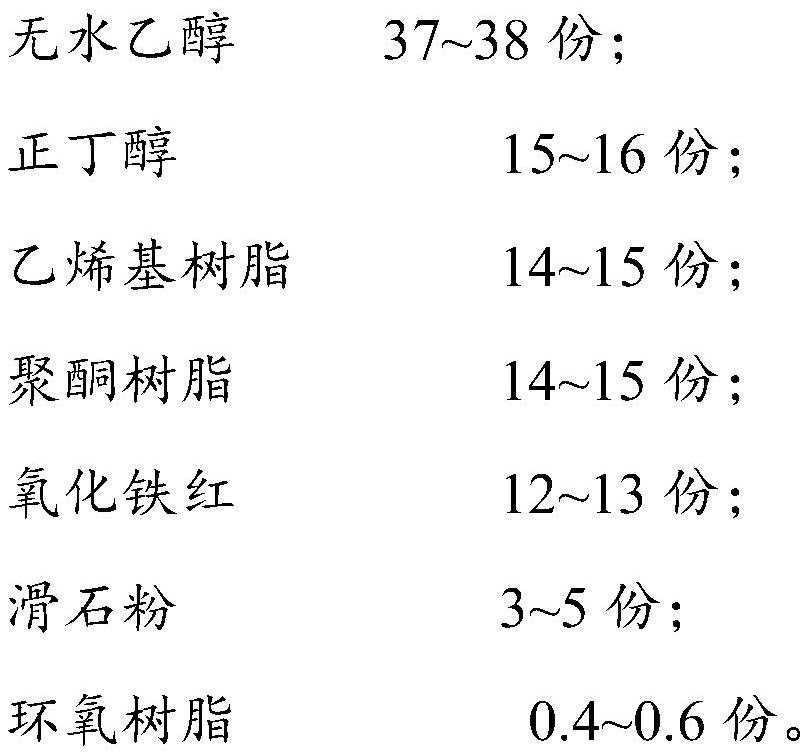

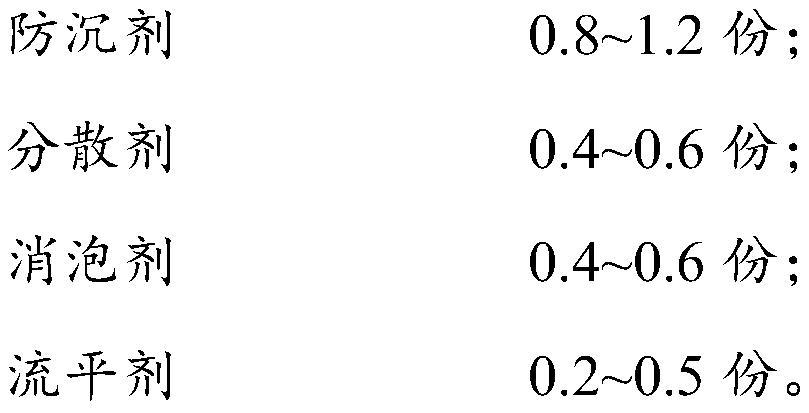

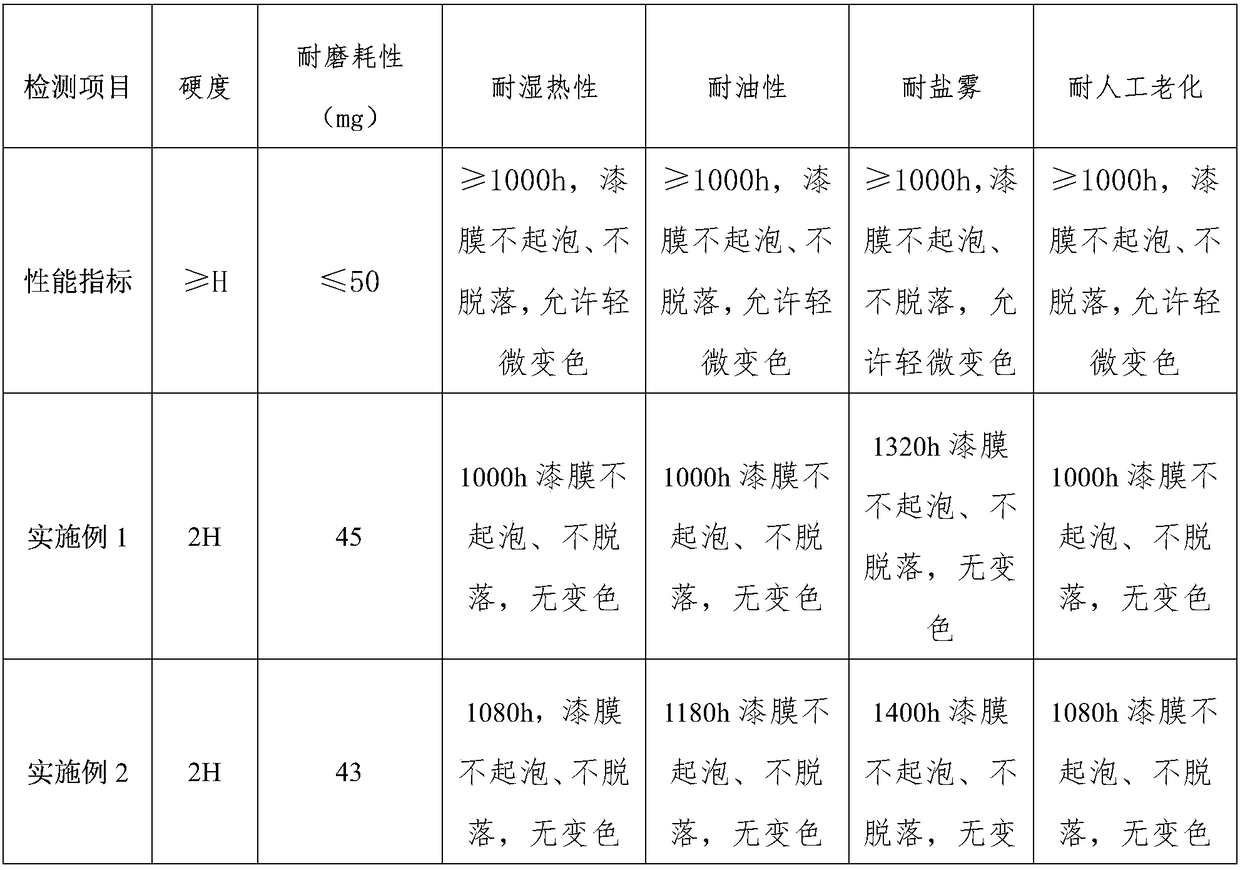

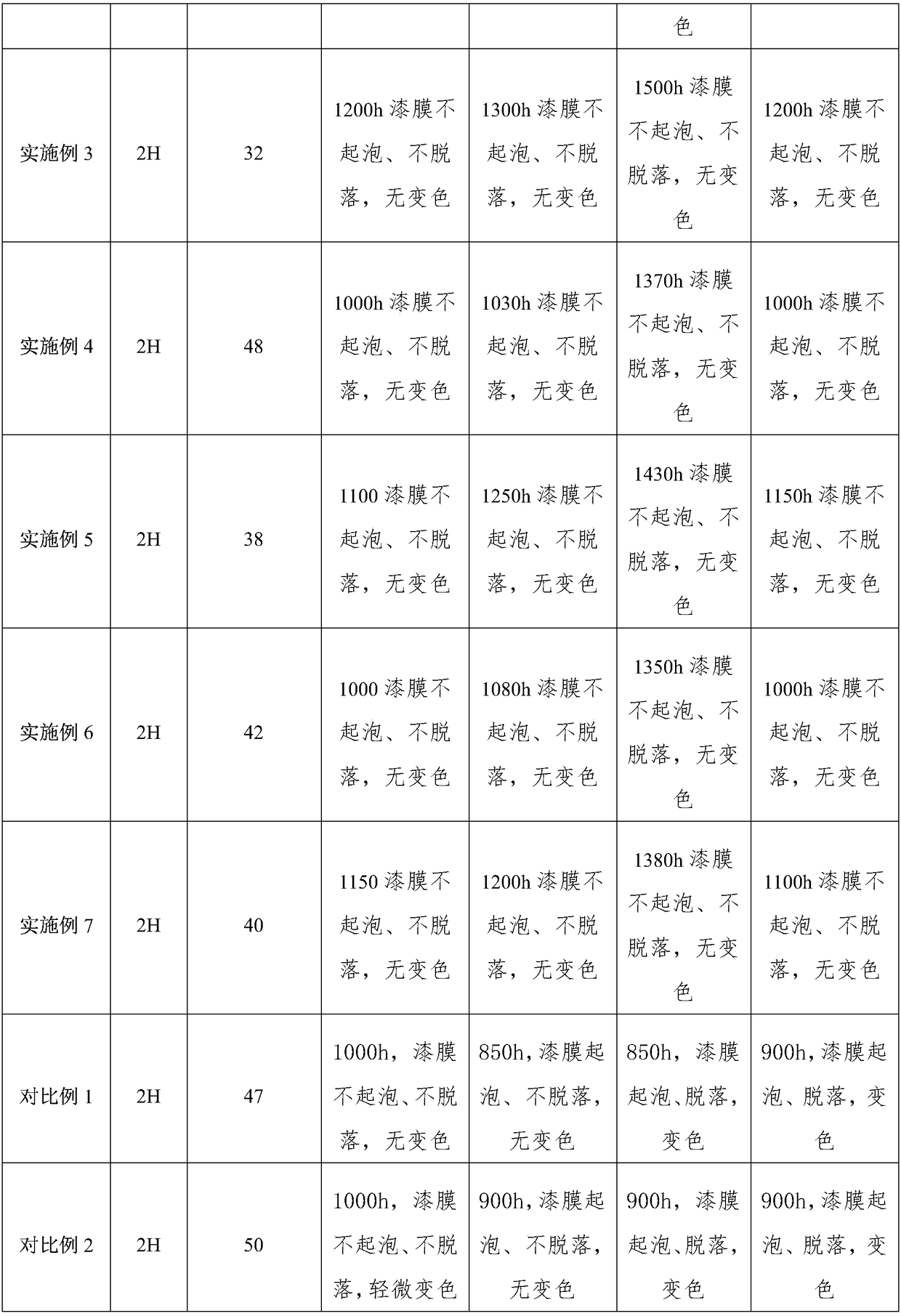

Protective coating applicable to surfaces of various substrates and preparation method thereof

ActiveCN112920715AStrong adhesionImprove hydrophobicityAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePolystyrene

The invention discloses a protective coating suitable for various base material surfaces and a preparation method thereof, and relates to the technical field of coatings. The invention provides a protective coating suitable for various substrate surfaces. The protective coating is mainly composed of absolute ethyl alcohol, n-butyl alcohol, vinyl resin, polyketone resin and the like. The protective coating provided by the invention is suitable for various materials of electrical equipment, such as inorganic materials (ceramic, concrete, cement, glass and the like), organic materials (such as polystyrene plastic, acrylic plates and the like), metals (cold-rolled steel plates, stainless steel plates and aluminum-coated zinc plates) and the like, and shows excellent adhesion to various base materials.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Polypropylene anti-aging coating

InactiveCN103897533AGood abrasion resistanceStrong ability to resist wind and sand impactCoatingsChemistryPolypropylene

The invention relates to a polypropylene anti-aging coating comprising the following components: a polyacrylic emulsion, sodium aluminosilicate, calcium carbonate, potassium tripolyphosphate, polyethylene glycol alkylaryl, and hydroxyethyl cellulose. The contents of the components comprise 50 parts of the polyacrylic emulsion, 12 parts of sodium aluminosilicate, 15 parts of calcium carbonate, 8 parts of potassium tripolyphosphate, 5 parts of polyethylene glycol alkylaryl, and 3 parts of hydroxyethyl cellulose. The coating can effectively inhibit bacteria and remove peculiar smells, purifies air, has the advantages of good erasibility, and strong ability to resist wind-blown sand shocking, has uniform coating layers without cracks, can be subjected to blade coating, roll coating and spray coating, and has especially remarkable anti-man-made aging performance.

Owner:QINGDAO XUANWEI COATING MATERIAL

Composite nanometer anti-aging fireproof coating

InactiveCN108373857AImprove anti-aging propertiesGood scrub resistanceFireproof paintsAntifouling/underwater paintsCross-linkMaterials science

The invention discloses a composite nanometer anti-aging fireproof coating. The composite nanometer anti-aging fireproof coating comprises, by weight, 30-40 parts of a copolymer emulsion, 25-35 partsof an ethylene-vinyl acetate copolymer, 12-15 parts of a cross-linked acrylate emulsion, 3-5 parts of cobalt naphthenate, 6-8 parts of propylene glycol, 5-9 parts of a filler, 9-14 parts of inorganicnano-powder and 2-4 parts of a film-forming aid. Compared with the coating without an inorganic nanocomposite material, the composite nanometer anti-aging fireproof coating has aging resistance improved by 50-120%. The composite nanometer anti-aging fireproof coating has excellent fireproof effects, good impact resistance, artificial aging resistance and strong adhesion. Through use of nano-silica, the composite nanometer anti-aging fireproof coating has lasting antibacterial effects. The composite nanometer anti-aging fireproof coating improves the washing resistance, water resistance and anti-sticking property by 1-5 times than those of the coating without an inorganic nanocomposite material.

Owner:青岛国福实业有限公司

Water-based environmental protection paint specially used for container and preparation method thereof

PendingCN109423177AEffective control of reaction speedSolve the shrinkage cavityAntifouling/underwater paintsPaints with biocidesWater basedNano al2o3

The invention provides water-based environmental protection paint specially used for a container, which belongs to the technical field of paint. The water-based environmental protection paint specially used for the container is prepared from, by weight, the following raw materials: 20-35 parts of water-based alkyd resin, 3-6 parts of a solvent, 1-2.5 parts of a pH regulating agent, 10-30 parts ofdeionized water, 0.3-0.4 part of a defoaming agent, 1-3 parts of a dispersant, 5-10 parts of organic bentonite, 0.1-0.5 part of a dryer, 1-2 parts of nanometer aluminum oxide, 1-3 parts of an ultraviolet ray absorbent, 0.2-0.5 part of graphene oxide, 20-30 parts of pigments and fillers, 0.5-1 part of a water-based oil resistance agent, 0.3-0.8 part of a wetting agent, and 5-10 parts of a poly(tetrafluoroethylene) solution, wherein the water-based alkyd resin is a water-soluble self-drying alkyd resin. A coating prepared by the water-based environmental protection paint specially used for the container of the invention has the characteristics of smooth surface without pinholes, oil resistance of more than 1000 h, and excellent stain resistance performance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Unmodified silica sol/polystyrene-acrylate nano core-shell emulsion and preparation method thereof

ActiveCN104262530BFast Nano Core-Shell Composite StructureObvious nano core-shell composite structurePolyesterEnvironmental resistance

The invention discloses an unmodified silica sol / polystyrene-acrylate nano core-shell emulsion and a preparation method thereof. Using commercially available alkaline silica sol, styrene, and acrylic ester monomers as the main raw materials, there is no need for tedious surface modification of nanoparticles. Under the action of reactive emulsifiers, the seed monomers will 2 Surface in-situ polymerization, followed by shell monomer polymerization to form high silica sol / polystyrene-acrylate nano-core-shell polymer emulsion, which has small particle size, high silicon content, high coating rate, stability, etc. Various properties. The method has simple production process and rapid synthesis, and the obtained composite latex has an obvious nano-core-shell composite structure, with nano-silica as the core and styrene-acrylic polyester as the shell; it has good water resistance, stain resistance, and heat resistance. Non-toxic, acid and alkali resistance and other properties, and environmental protection, flame retardant, good transparency. It can be widely used in various coating fields such as high-grade architectural coatings, electronic packaging materials, ship anti-corrosion coatings, etc.

Owner:广西亚多漆业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com