Protective coating applicable to surfaces of various substrates and preparation method thereof

A technology for protective coatings and substrate surfaces, applied in the field of coatings, to achieve excellent artificial aging resistance, strong acid and alkali corrosion resistance, and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

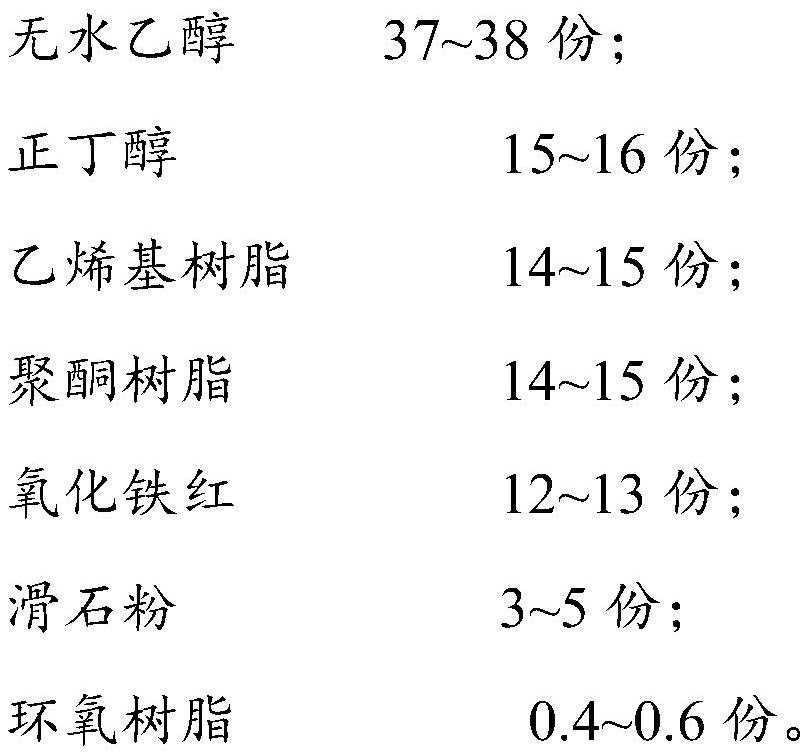

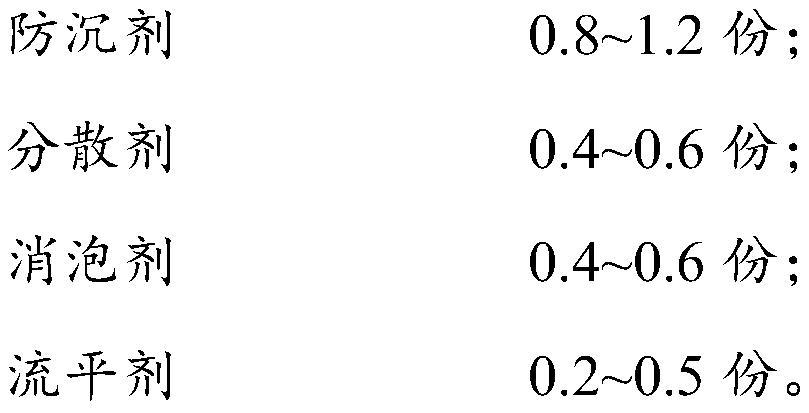

Embodiment 1

[0034] This embodiment provides a protective coating suitable for the surface of various substrates. The resin system of the coating contains a large number of hydroxyl groups, and these hydroxyl groups can form hydrogen bonds with ethanol and n-butanol, so it can be dissolved in ethanol and n-butanol middle. And the coating is made by mixing the following materials by weight and filtering them through a 80-100 mesh filter screen: 14-15 parts of vinyl resin, 14-15 parts of A181 polyketone resin, 37-38 parts of absolute ethanol , 15~16 parts of n-butanol, 0.4~0.6 parts of E44 epoxy resin, 0.8~1.2 parts of R~972 anti-settling agent, 12~13 parts of iron oxide red, 3~5 parts of talcum powder, 0.4~ 0.6 parts of Deqian dispersant of model 923S, 0.4-0.6 parts of Deqian defoamer of model 5500 and 0.2-0.5 parts of Deqian leveling agent of model 455,

[0035] The dispersant, defoamer and leveling agent used in this example are all produced by Deqian Chemical Co., Ltd. Any dispersant, ...

Embodiment 2

[0042] A kind of preparation method that is applicable to the protective coating of multiple base material surface is as follows:

[0043] (1) Take by weight 37.5 parts of absolute ethanol, 15 parts of n-butanol, 0.5 parts of E44 epoxy resin, 0.5 parts of 923S dispersant, 0.5 parts of 5500 defoamer, 0.3 parts of 455 fluid Leveling agent and 14.5 parts of A181 polyketone resin are added to the dispersion container, and dispersed for 25 minutes at a stirring speed of 200 rpm;

[0044] (2) Add 12 parts of iron oxide red and 3.5 parts of talcum powder in turn, and disperse for 50 minutes at a stirring speed of 500 rpm;

[0045] (3) Add the homogeneously dispersed slurry in step (2) into a conical mill and grind it to a fineness of 70 μm, and then add it to a dispersion container;

[0046] (4) Add 14.5 parts of vinyl resin and 1 part of R~972 anti-sedimentation agent, adjust the stirring speed to 800 rpm, continue stirring for 60 minutes, filter and pack with an 80-mesh filter to ...

Embodiment 3

[0049] A kind of preparation method that is applicable to the protective coating of multiple base material surface is as follows:

[0050] Preparation of a high-adhesion protective coating suitable for the surface of various substrates of power equipment:

[0051] (1) Take by weight 38 parts of absolute ethanol, 15.5 parts of n-butanol, 0.5 part of E44 epoxy resin, 0.5 part of 923S dispersant, 0.55 part of 5500 defoamer, 0.35 part of 455 fluid Leveling agent and 14.8 parts of A181 polyketone resin are added to the dispersion container, and dispersed for 20 minutes at a stirring speed of 300 rpm;

[0052] (2) Add 12.5 parts of iron oxide red and 4 parts of talcum powder in turn, and disperse for 40 minutes at a stirring speed of 800 rpm;

[0053] (3) Add the homogeneously dispersed slurry in step (2) into a conical mill and grind it to a fineness of 80 μm, and then add it to a dispersion container;

[0054] (4) Add 14 parts of vinyl resin and 0.9 parts of R-972 anti-sedimenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com