Aqueous modified acrylic emulsion as well as preparation method and application thereof

A technology of acrylic emulsion and water-based fluorine, applied in the field of emulsion, can solve the problem of high VOC content, and achieve the effect of excellent solvent resistance and excellent impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

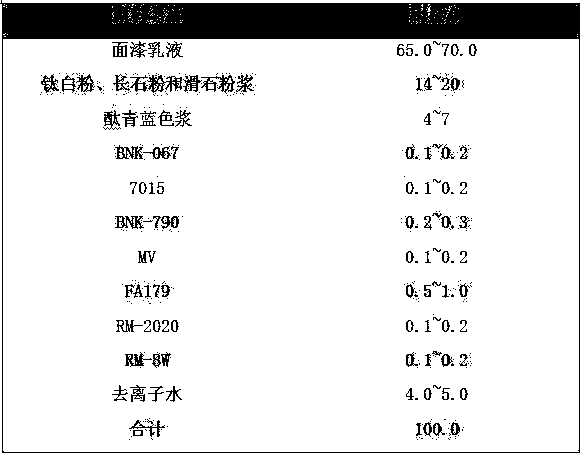

Method used

Image

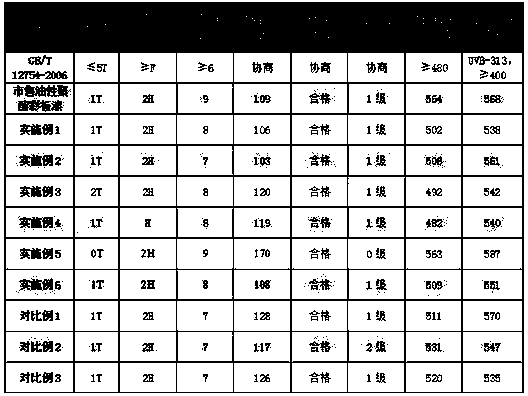

Examples

Embodiment 1

[0025] A fluorine-modified acrylic emulsion, by mass percentage, water 56%, alkylphenol polyoxyethylene ether sodium sulfate 1.3%, hexafluorobutyl acrylate 3.5%, butyl acrylate 13%, methyl methacrylate 11% , styrene 6%, β-acryloyloxypropionic acid 0.3%, acrylic acid 0.4%, hydroxyethyl acrylate 2%, C 10 Vinyl tertiary carbonate 1.5%, acrylamide 0.48%, diacetone acrylamide (DAAM) 2.15%, adipate dihydrazide (ADH) 1.1%, persulfate 0.27%, organic amine AMP-95 1%.

[0026] Prepare as follows:

[0027] (1) Take 1 / 2 of water and 1 / 4 of sodium alkylphenol polyoxyethylene ether sulfate into the reaction kettle, start heating and stirring.

[0028] (2) Preparation of emulsion: Take the remaining water and emulsifier and add them to the emulsification tank, start stirring, and then add hexafluorobutyl acrylate, butyl acrylate, methyl methacrylate, styrene, β-acryloyl Oxypropionic Acid, Acrylic Acid, Hydroxyethyl Acrylate, C 10 Vinyl tert-carbonate, acrylamide, diacetone acrylamide and ...

Embodiment 2

[0033] Fluorine-modified acrylic emulsion, by mass percentage, water 56%, alkylphenol polyoxyethylene ether sodium sulfate 1.3%, hexafluorobutyl acrylate 3.5%, butyl acrylate 13%, methyl methacrylate 11%, benzene Ethylene 6%, β-acryloxy propionic acid 0.25%, acrylic acid 0.45%, hydroxyethyl acrylate 2%, C 10 Vinyl tertiary carbonate 1.5%, acrylamide 0.48%, diacetone acrylamide (DAAM) 2.15%, adipate dihydrazide (ADH) 1.1%, persulfate 0.27%, organic amine AMP-95 1%.

[0034] Prepare as follows:

[0035] (1) Take 1 / 2 of water and 1 / 4 of sodium alkylphenol polyoxyethylene ether sulfate into the reaction kettle, start heating and stirring.

[0036] (2) Preparation of emulsion: Take the remaining water and emulsifier and add them to the emulsification tank, start stirring, and then add hexafluorobutyl acrylate, butyl acrylate, methyl methacrylate, styrene, β-acryloyl Oxypropionic Acid, Acrylic Acid, Hydroxyethyl Acrylate, C 10 Vinyl tert-carbonate, acrylamide, diacetone acrylamid...

Embodiment 3

[0041] Fluorine-modified acrylic emulsion, by mass percentage, water 56%, alkylphenol polyoxyethylene ether sodium sulfate 1.3%, hexafluorobutyl acrylate 3.5%, butyl acrylate 13.6%, methyl methacrylate 11.6%, benzene Ethylene 6%, β-acryloxypropionic acid 0.3%, Acrylic acid 0.4%, Hydroxyethyl acrylate 2%, C 10 Vinyl tertiary carbonate 0.3%, acrylamide 0.48%, diacetone acrylamide (DAAM) 2.15%, adipate dihydrazide (ADH) 1.1%, persulfate 0.27%, organic amine AMP-95 1%.

[0042] Prepare as follows:

[0043] (1) Take 1 / 2 of water and 1 / 4 of sodium alkylphenol polyoxyethylene ether sulfate into the reaction kettle, start heating and stirring.

[0044] (2) Preparation of emulsion: Take the remaining water and emulsifier and add them to the emulsification tank, start stirring, and then add hexafluorobutyl acrylate, butyl acrylate, methyl methacrylate, styrene, β-acryloyl Oxypropionic Acid, Acrylic Acid, Hydroxyethyl Acrylate, C 10 Vinyl tert-carbonate, acrylamide, diacetone acrylamide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com