Nanometer anticorrosion coating and preparation method thereof

A kind of anti-corrosion coating, nanotechnology, applied in the direction of anti-corrosion coating, anti-fouling/underwater coating, coating, etc., can solve the problem of poor chemical resistance and artificial aging resistance, impact resistance, poor adhesion of artificial aging resistance , do not have antibacterial function and other problems, to achieve long-lasting antibacterial effect, excellent anti-corrosion performance, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

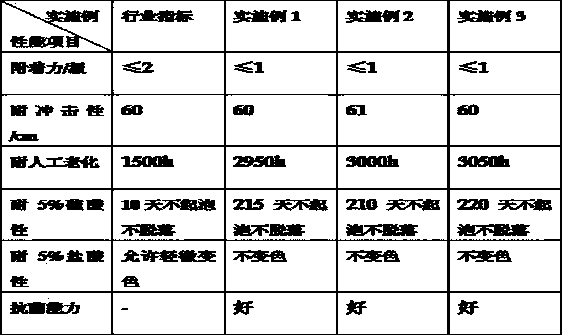

Examples

Embodiment 1

[0017] A kind of nano anticorrosion coating, its component is made up of following composition by weight percentage: 80% A component and 20% B component; Described A component comprises following component by weight: 30 parts of styrene- Butadiene polymer, 20 parts of nano silicon dioxide, 1 part of auxiliary agent, 0.4 part of mixed solvent; said auxiliary agent includes defoamer, leveling agent and dispersant; said mixed solvent includes 1,4-butanediene Alcohol and trimethylolethane; The B component includes the following components in parts by weight: 15 parts of N-(2-mercaptoethyl) pentanoyl, 10 parts of melamine-formaldehyde resin, 20 parts of butyl glycol , 15 parts of talcum powder. Additives include defoamer, leveling agent and dispersant in a weight ratio of 1:1:2. The volume ratio of 1,4-butanediol and trimethylolethane in the mixed solvent is 3:2. The average particle diameter of nano silicon dioxide is 25nm. The leveling agent is polydimethylsiloxane. The dispe...

Embodiment 2

[0023] A kind of nano anticorrosion coating, its component is made up of following composition by weight percentage: 90% of A component and 10% of B component; Described A component comprises following component by weight: 50 parts of styrene- Butadiene polymer, 25 parts of nano silicon dioxide, 8 parts of auxiliary agent, 0.6 part of mixed solvent; said auxiliary agent includes defoamer, leveling agent and dispersant; said mixed solvent includes 1,4-butanediene Alcohol and trimethylolethane; The B component includes the following components in parts by weight: 20 parts of N-(2-mercaptoethyl) pentanoyl, 20 parts of melamine-formaldehyde resin, 30 parts of butyl glycol , 20 parts of talcum powder. Additives include defoamer, leveling agent and dispersant in a weight ratio of 1:1:2. The volume ratio of 1,4-butanediol and trimethylolethane in the mixed solvent is 3:2. The average particle diameter of nano silicon dioxide is 35nm. The leveling agent is polydimethylsiloxane. Th...

Embodiment 3

[0029] A kind of nano anticorrosion coating, its component is made up of following composition by weight percentage: A component of 85% and B component of 15%; Described A component comprises following component by weight part: 40 parts of styrene- Butadiene polymer, 23 parts of nano silicon dioxide, 4 parts of auxiliary agent, 0.5 part of mixed solvent; said auxiliary agent includes defoamer, leveling agent and dispersant; said mixed solvent includes 1,4-butanediene Alcohol and trimethylolethane; The B component includes the following components in parts by weight: 17 parts of N-(2-mercaptoethyl) pentanoyl, 15 parts of melamine-formaldehyde resin, 25 parts of butyl glycol , 17 parts of talcum powder. Additives include defoamer, leveling agent and dispersant in a weight ratio of 1:1:2. The volume ratio of 1,4-butanediol and trimethylolethane in the mixed solvent is 3:2. The average particle diameter of nano silicon dioxide is 30nm. The leveling agent is polydimethylsiloxane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com