Unmodified silica sol/polyacrylate core-shell emulsion and preparation method thereof

A polyacrylate, core-shell emulsion technology, applied in the field of environmentally friendly nano-core-shell water-based emulsions, can solve the problems of failing to maximize the characteristics of nanomaterials, difficult to control reaction conditions, and limited improvement in emulsion performance, and achieve excellent artificial aging resistance. , the effect of fast synthesis and good stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

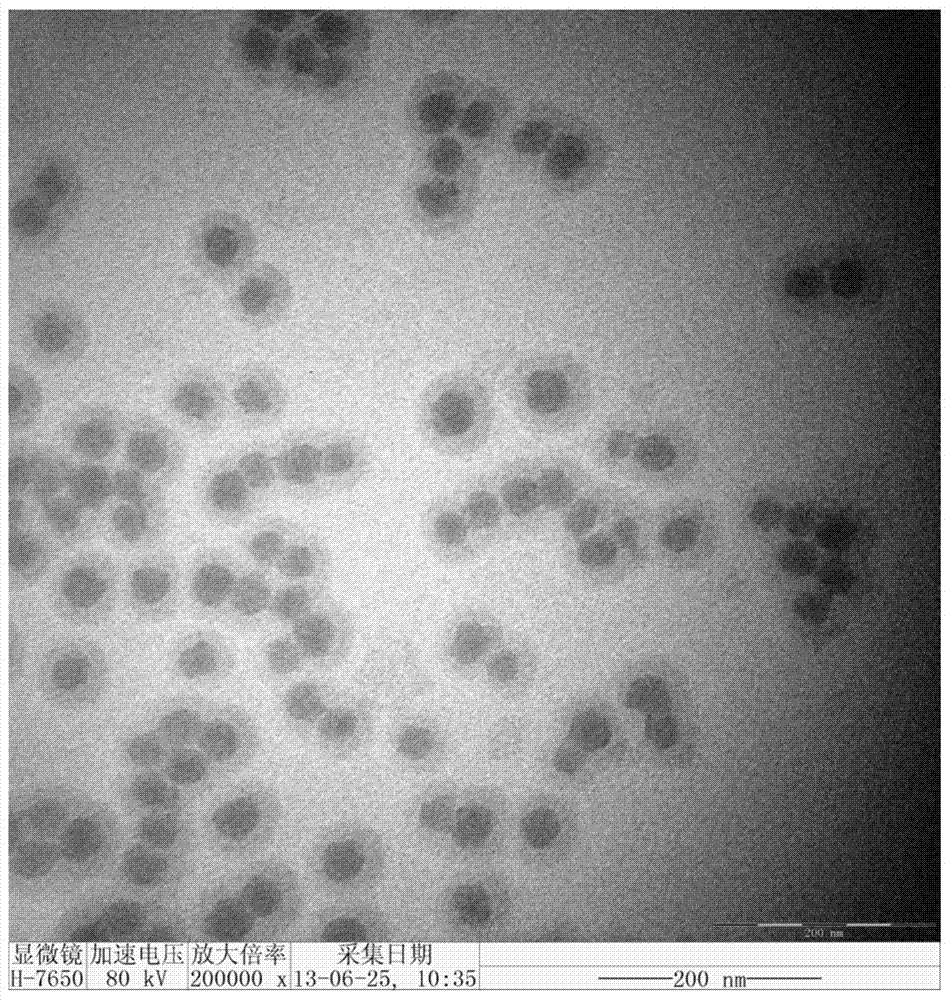

Image

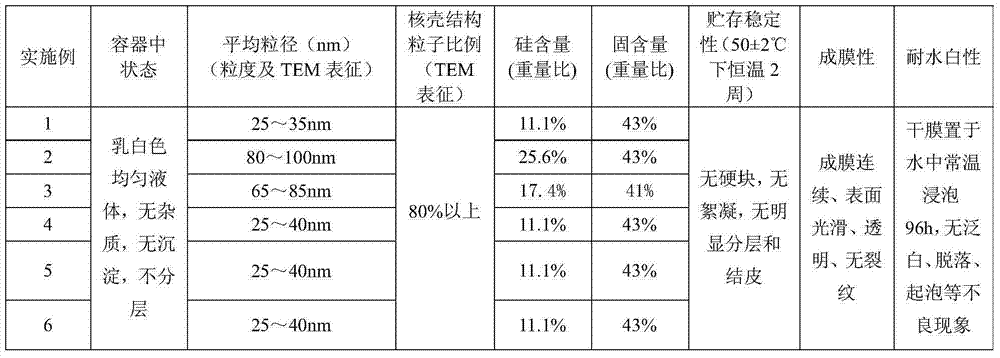

Examples

Embodiment 1

[0031] Seed emulsion polymerization: place the four-necked flask equipped with a stirrer, reflux condenser, thermometer and titration funnel in a constant temperature water bath, stir at a constant speed of 300 to 400r / min, and 2 Under protection, in parts by weight, add 80g deionized water, 2g reactive emulsifier allyloxynonylphenoxypropanol polyoxyethylene ether, add 120g of commercially available alkaline silica sol (with In terms of silicon dioxide, the weight content of silicon is 30%, the average particle diameter is 10nm, and the pH value is 9), uniformly dispersed; gradually warming up to 75°C, and keeping a constant temperature, add 0.10g ammonium persulfate (dissolved in 10 parts of distilled water Make a solution and add), start to titrate 5g of acrylate mixed monomer (MMA / n-BA / MAA=46 / 50 / 4, mass ratio), drop it in 10 minutes, keep it warm for 1 hour, and obtain the seed emulsion;

[0032] Polymerization of shell monomers: Add 2g of non-reactive emulsifier sodium la...

Embodiment 2

[0034] Seed emulsion polymerization: place the four-necked flask equipped with a stirrer, reflux condenser, thermometer and titration funnel in a constant temperature water bath, stir at a constant speed of 300 to 400r / min, and 2 Under protection, in parts by weight, add 150g deionized water, 6g reactive emulsifier allyloxy hydroxypropyl sodium sulfonate, after 10 minutes, add 320g of commercially available alkaline silica sol (calculated as silicon dioxide, The weight content of silicon is 50%, and average particle diameter is 30nm, and pH value is 10), uniformly dispersed; Be warming up to 75 ℃ gradually, and keep constant temperature, add 0.40g ammonium persulfate (dissolve in 10g distilled water and make solution add), Start to titrate 20g of acrylate mixed monomer (ethyl methacrylate / n-butyl acrylate / N-methylolacrylamide / acrylic acid=46 / 25 / 25 / 4, mass ratio), drop it in 20 minutes, and keep it warm 1 hour, obtain seed emulsion;

[0035] shell monomer polymerization: add...

Embodiment 3

[0037] Seed emulsion polymerization: place the four-necked flask equipped with a stirrer, reflux condenser, thermometer and titration funnel in a constant temperature water bath, stir at a constant speed of 300 to 400r / min, and 2 Under protection, in parts by weight, add 120g deionized water, 4g reactive emulsifier allyloxy fatty alcohol oxyethylene ether ammonium sulfate, add 200g of commercially available alkaline silica sol (calculated as silicon dioxide) after 10 minutes , the weight content of silicon is 40%, and average particle diameter is 20nm, and pH value is 9), uniform dispersion; Gradually warming up to 75 ℃, and keep constant temperature, add 0.30g ammonium persulfate (dissolve in 10g distilled water and make solution add) , start titration of 10g acrylate mixed monomer (ethyl methacrylate / n-butyl acrylate / hydroxyethyl acrylate / acrylic acid=46 / 30 / 20 / 4, mass ratio), drop it in 30 minutes, and keep it warm for 1 hour , to obtain seed emulsion;

[0038] Shell mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com