Triptycene derivative modified waterborne acrylic resin and preparation method thereof

A technology of water-based acrylic and its derivatives, which can be used in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc. It can solve the problems of imperfect performance of water-based acrylic resins, and achieve good artificial aging resistance and compatibility Good and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

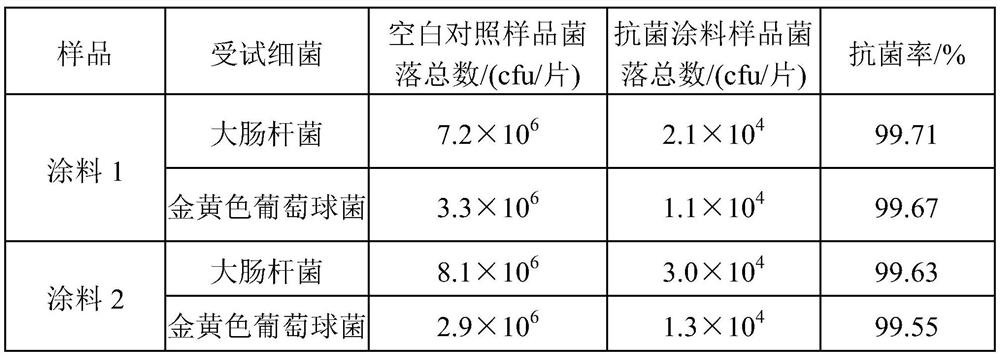

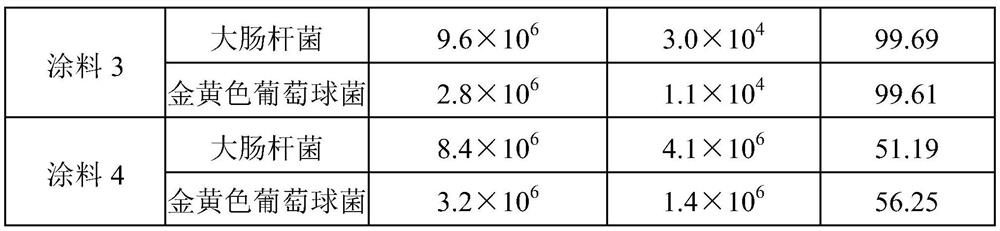

Examples

Embodiment 1

[0027] A tricene derivative-modified water-based acrylic resin, in parts by weight, its components are: 4.0 parts of tricene derivatives, 2.0 parts of hydroxyethyl methacrylate, 0.5 parts of benzoyl peroxide, three parts 4.0 parts of methylolpropane trimethacrylate, 3.5 parts of acrylic acid, 20.0 parts of methyl methacrylate, 15.0 parts of butyl methacrylate, 15.0 parts of lauryl methacrylate, 3.0 parts of vinyltrimethoxysilane, 15.0 parts of diethylene glycol monobutyl ether, 3.0 parts of triethylamine, and 95.0 parts of deionized water.

[0028] In the present embodiment, a preparation method of a tridecene derivative-modified water-based acrylic resin comprises the following steps:

[0029] a), in the titration tank, in parts by weight of the formula, methyl methacrylate, butyl methacrylate, lauryl methacrylate, hydroxyethyl methacrylate, 1 / 3 benzoyl peroxide Stir evenly to obtain mixed solution I;

[0030] b), in the titration tank, by weight of the formula, stir trimet...

Embodiment 2

[0034] A tricene derivative-modified water-based acrylic resin, in parts by weight, the components are: in parts by weight, the components are: 3.0 parts of tricene derivatives, 3.0 parts of hydroxypropyl methacrylate, 0.6 parts of benzoyl peroxide, 6.0 parts of trimethylolpropane trimethacrylate, 4.0 parts of acrylic acid, 8.0 parts of methyl acrylate, 15.0 parts of isobornyl acrylate, 10.0 parts of hexyl acrylate, thirteen carbon methacrylate 10.0 parts of esters, 15.0 parts of octadecyl acrylate, 2.0 parts of vinyltrimethoxysilane, 20.0 parts of propylene glycol methyl ether acetate, 3.0 parts of ammonia water, and 100.0 parts of deionized water.

[0035] The invention provides a preparation method of a tridecene derivative-modified water-based acrylic resin, comprising the following steps:

[0036] a), in the titration tank, in parts by weight of the formula, mix methyl acrylate, isobornyl acrylate, hexyl acrylate, tridecyl methacrylate, octadecyl acrylate, hydroxypropyl m...

Embodiment 3

[0041]A tricene derivative-modified water-based acrylic resin, in parts by weight, the components are: in parts by weight, the components are: 3.5 parts of tricene derivatives, 3.0 parts of hydroxybutyl methacrylate, 0.5 parts of benzoyl peroxide, 4.0 parts of trimethylolpropane trimethacrylate, 3.5 parts of acrylic acid, 16.0 parts of cyclohexyl methacrylate, 25.0 parts of octadecyl acrylate, 3.0 parts of vinyltrimethoxysilane, 14.0 parts of diethylene glycol monobutyl ether, 3.2 parts of triethylamine, and 90.0 parts of deionized water.

[0042] The invention provides a preparation method of a tridecene derivative-modified water-based acrylic resin, comprising the following steps:

[0043] a), in the titration tank, in parts by weight of the formula, cyclohexyl methacrylate, octadecyl acrylate, hydroxybutyl methacrylate, 1 / 3 benzoyl peroxide are stirred to obtain mixed solution I;

[0044] b), in the titration tank, by weight of the formula, stir trimethylolpropane trimetha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com