Tripolyindanone derivative modified acrylic resin water-based paint

An acrylic resin and water-based coating technology, applied in antifouling/underwater coatings, luminescent coatings, coatings, etc., can solve problems such as loss of protective effect of coatings, inability to display luminous effects, and no change in the object surface, and achieve good results. Antibacterial function, good artificial aging resistance, effect of improving fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A water-based acrylic resin A modified by melindone derivatives, the components of which are: 2.5 parts of melindone derivatives, 6.5 parts of isophorone diisocyanate, 0.6 parts of hydroxyethyl acrylate, 0.4 parts of benzoyl peroxide, 3.5 parts of acrylic acid, 50.0 parts of methyl methacrylate, 65.0 parts of butyl methacrylate, 5.0 parts of allyl glycidyl ether, 12.0 parts of propylene glycol butyl ether, 12.0 parts of propylene glycol methyl ether acetate , 7.0 parts of N-methylpyrrolidone, 3.2 parts of triethylamine, and 150.0 parts of deionized water.

[0031] A kind of preparation method of Triindanone derivative modified waterborne acrylic resin A in the present embodiment, comprises the following steps:

[0032] a. In the reactor, add N-methylpyrrolidone, triindone derivatives, and isophorone diisocyanate in sequence according to the weight of the formula, and heat up to react;

[0033] b. Then add hydroxyethyl acrylate, keep warm and react at 80-86°C, measure t...

Embodiment 2

[0040] A water-based acrylic resin B modified by merindone derivatives, the components of which are: 2.0 parts of merindone derivatives, 6.0 parts of isophorone diisocyanate, 0.8 parts of hydroxyethyl acrylate, 0.5 parts of benzoyl peroxide, 3.8 parts of acrylic acid, 48.0 parts of isobornyl acrylate, 55.0 parts of lauryl methacrylate, 7.0 parts of allyl glycidyl ether, 18.0 parts of alcohol ester dodecane, 7.0 parts of N-methylpyrrolidone parts, ammonia water 2.5 parts, deionized water 145.0 parts.

[0041]The present invention provides a kind of preparation method of Triindanone derivative modified water-based acrylic resin B, comprising the following steps:

[0042] a. In the reactor, add N-methylpyrrolidone, triindone derivatives, and isophorone diisocyanate in sequence according to the weight of the formula, and heat up to react;

[0043] b. Then add hydroxyethyl acrylate, keep warm and react at 80-86°C, measure the NCO value, and when it is consistent with the design va...

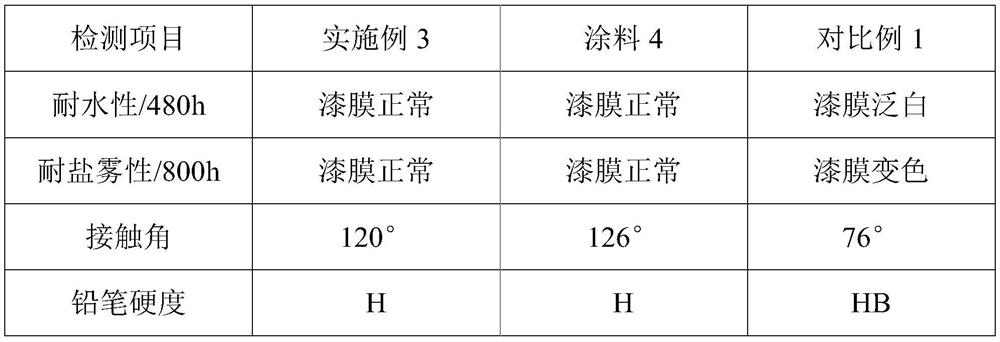

Embodiment 3

[0050] A melindone derivative modified acrylic resin water-based coating, which is composed of 150.0 parts of merindone derivative modified water-based acrylic resin A, 25.0 parts of fluorine-modified water-based acrylic resin, and a leveling agent in parts by weight 0.4 parts, 0.4 parts of wetting agent, 0.5 parts of defoaming agent, 0.6 parts of pH regulator, 0.8 parts of dispersant, 4.5 parts of diatomaceous earth, 6.0 parts of nano silicon dioxide, 5.0 parts of zinc phosphate, 25.0 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com