Water-based environmental protection paint specially used for container and preparation method thereof

An environmentally friendly coating and container technology, applied in the field of coatings, can solve the problems of poor stain resistance and oil resistance, easy to produce pinholes, etc., and achieve excellent stain resistance, avoid shrinkage cavities, and excellent oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

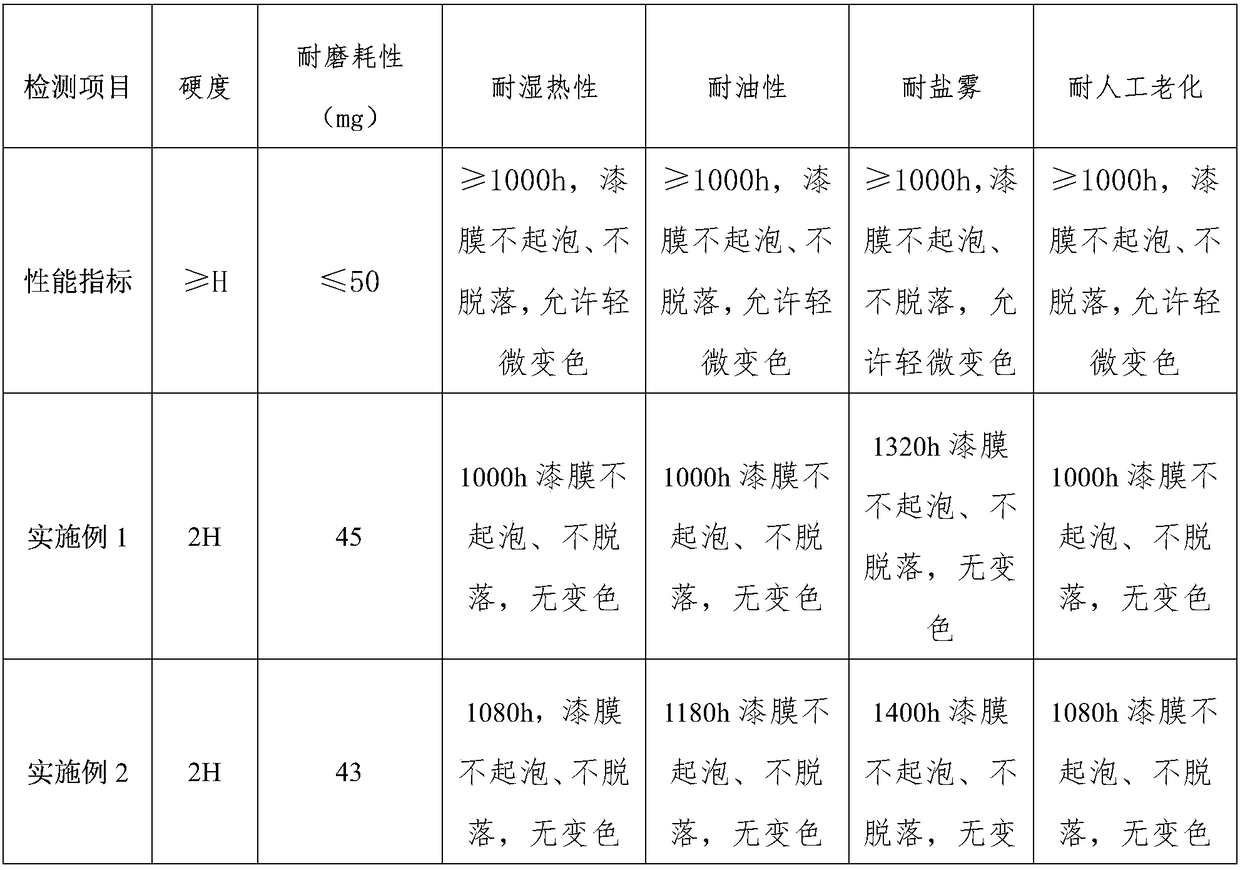

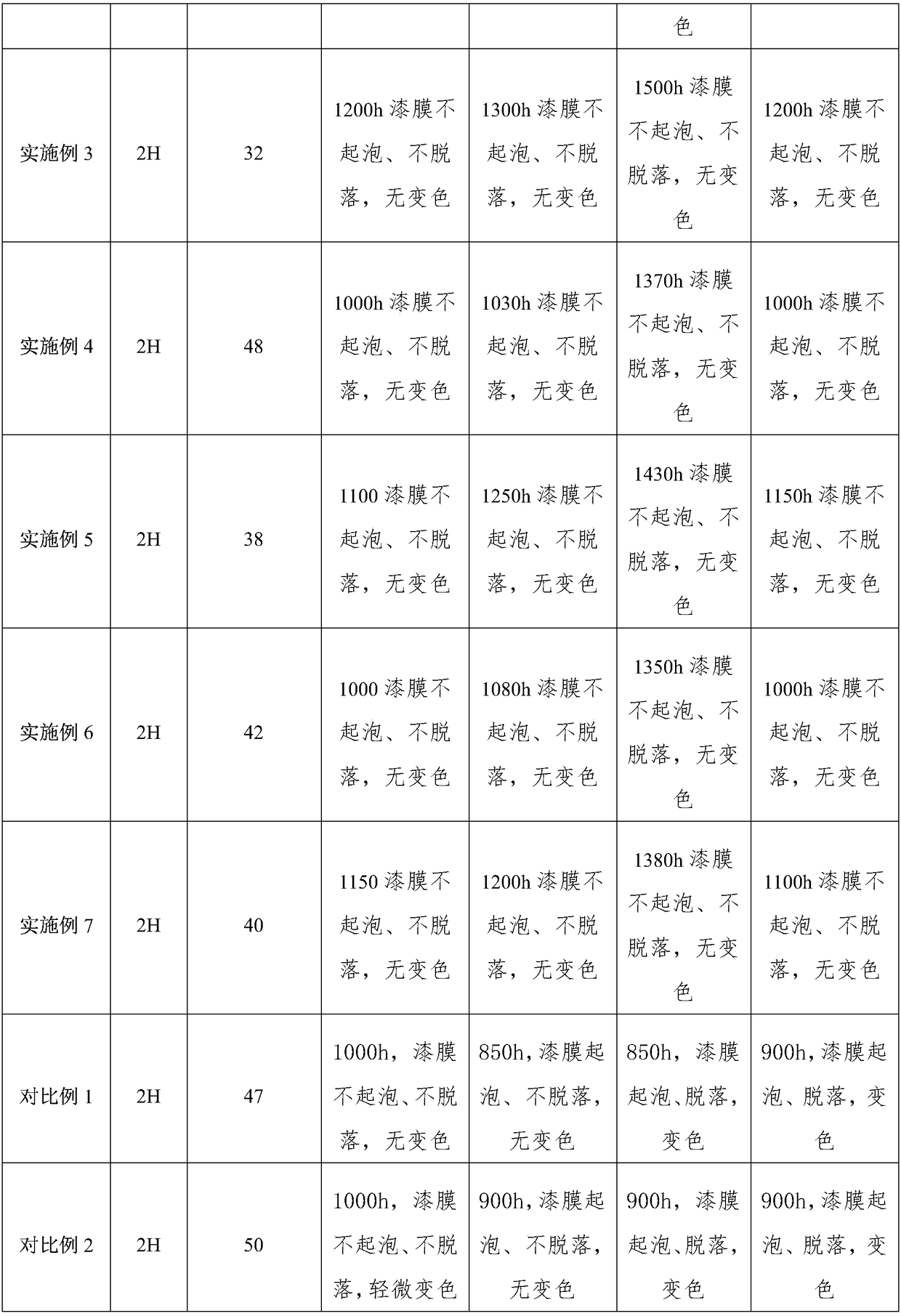

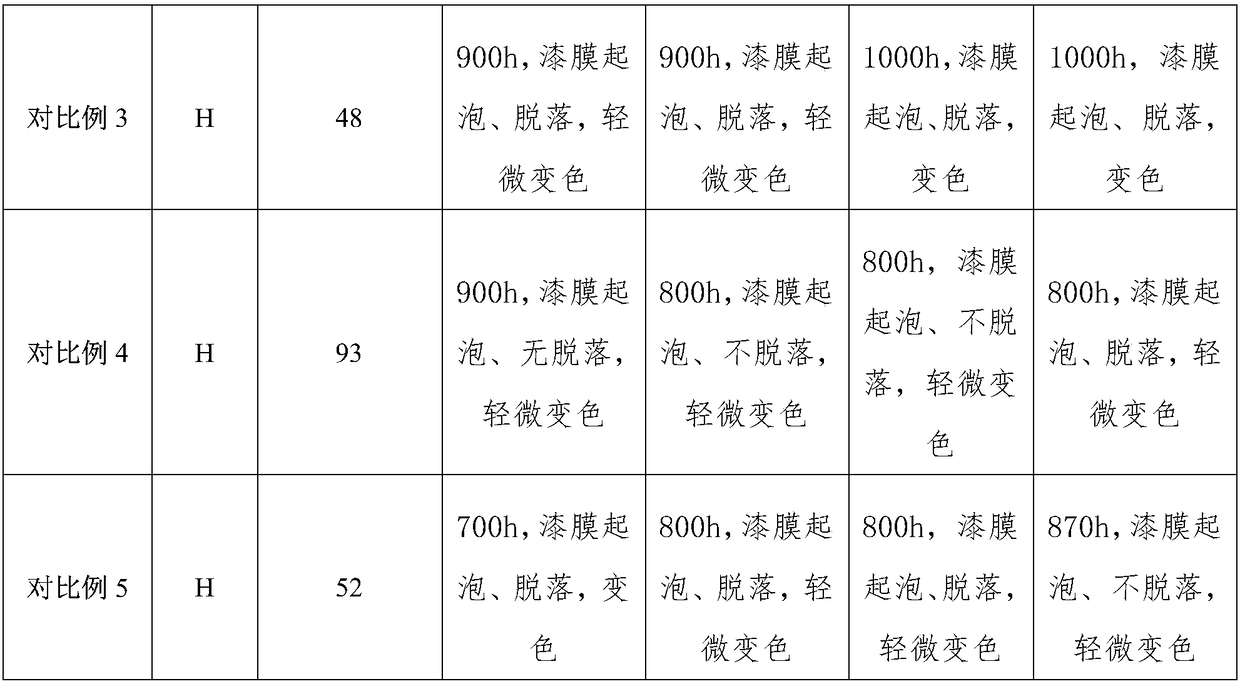

Examples

Embodiment 1

[0029] In this example, the special water-based environmental protection coating for containers is prepared from the following raw materials in parts by weight: 20 parts of water-based alkyd resin, 3 parts of dipropylene glycol butyl ether, 1.2 parts of AMP-95 multifunctional amine additive, 17 parts of deionized water, 0.3 parts of BYK028 defoamer, 1 part of BYK-190 dispersant, 10 parts of organic bentonite, 0.2 parts of OS123 drier, 1 part of nano-alumina, 1 part of WP-122 ultraviolet absorber, graphene oxide 0.3 parts, 23 parts of carbon black, 0.5 parts of polyether modified dimethyl polysiloxane, 0.3 parts of wetting agent, 5 parts of polytetrafluoroethylene solution; wherein the water-based alkyd resin is water-soluble self-drying alkyd resin.

Embodiment 2

[0031] In this example, the special water-based environmental protection paint for containers is prepared from the following raw materials in parts by weight: 25 parts of water-based alkyd resin, 3 parts of dipropylene glycol methyl ether, 1 part of AMP-95 multifunctional amine additive, 10 parts of deionized water, 0.3 parts of 902W defoamer, 1 part of Tego TEGO4100 dispersant, 5 parts of organic bentonite, 0.1 part of OS123 drier, 1 part of nano-alumina, 1 part of UV-770 ultraviolet absorber, graphene oxide 0.2 parts, 20 parts of 1500-mesh precipitated barium sulfate, 0.5 parts of polyether modified dimethyl polysiloxane, 0.4 parts of wetting agent, 5 parts of polytetrafluoroethylene solution; wherein the water-based alkyd resin is a water-soluble self- Dry alkyd resin.

Embodiment 3

[0033] In this example, the special water-based environmental protection paint for containers is prepared from the following raw materials in parts by weight: 25 parts of water-based alkyd resin, 5 parts of dipropylene glycol methyl ether, 2 parts of AMP-95 multifunctional amine additive, 25 parts of deionized water, 0.3 parts of Tego TEGO902W defoamer, 2 parts of Tego TEGO760W dispersant, 7 parts of organic bentonite, 0.3 parts of OS123 drier, 1.5 parts of nano-alumina, 1.5 parts of UV-770 ultraviolet absorber, 0.3 parts of graphene oxide, 15 parts of composite zinc phosphate, 8 parts of precipitated barium sulfate of 1500 mesh, 0.7 parts of polyether modified dimethyl polysiloxane, 0.6 parts of wetting agent, 10 parts of polytetrafluoroethylene solution; The water-based alkyd resin is a water-soluble self-drying alkyd resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| wear coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com