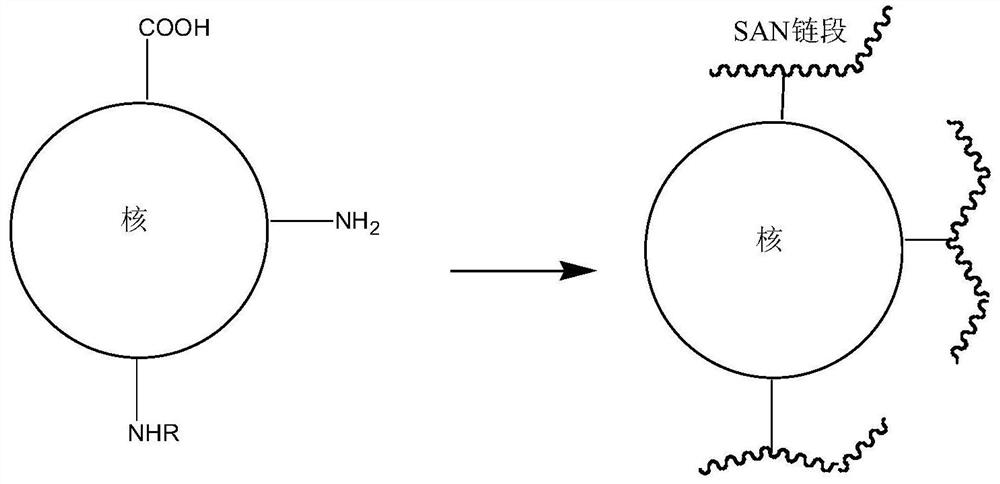

A kind of acrylate-styrene-acrylonitrile graft copolymer and preparation method thereof

A technology of graft copolymer and acrylate, which is applied in the field of acrylate-styrene-acrylonitrile graft copolymer and its preparation, can solve the problems of cumbersome operation, difficult large-scale application, and difficult preparation of vinyl monomers. Achieve the effect of simple process, convenient process control, stable and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

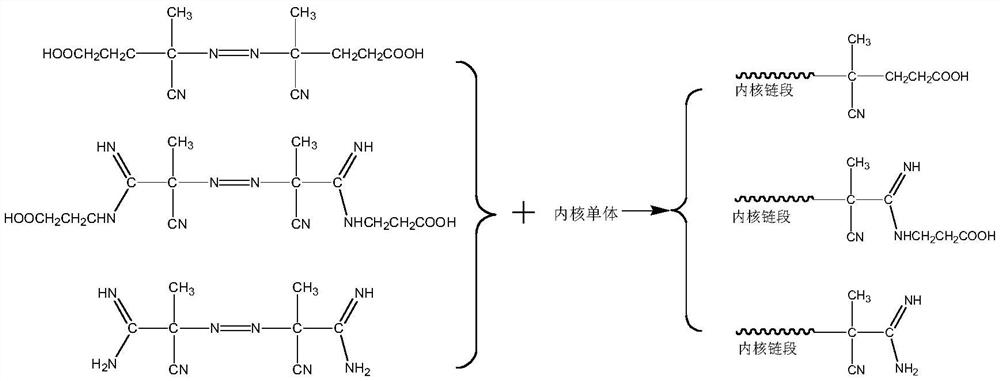

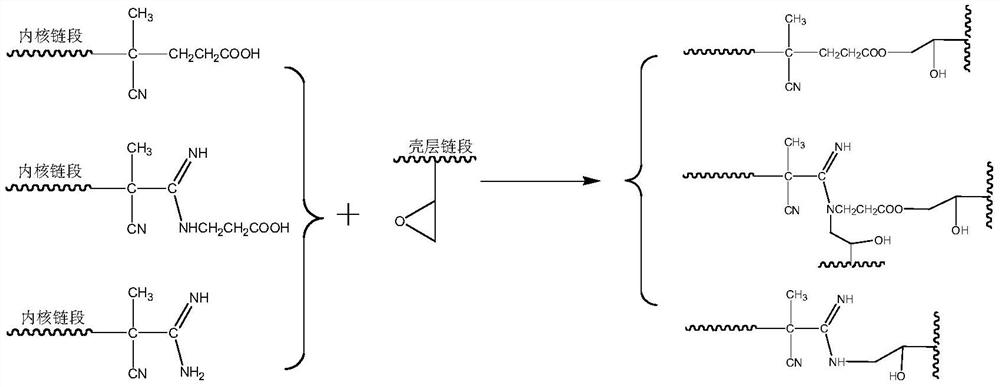

Method used

Image

Examples

Embodiment 1

[0025] (1) Add 1200g deionized water to the reaction kettle, add 6.4g sodium lauryl sulfate, 2.4g 4,4'-azobis(4-cyanovaleric acid), 40g butyl acrylate, methyl Ethylene glycol acrylate 0.2g, stirred and emulsified for 0.5h. The temperature was raised to 70° C., and after 0.5 h of reaction, a mixture of 760 g of butyl acrylate and 3.8 g of ethylene glycol methacrylate was added dropwise, continued for 2 h, and kept warm for 1 h.

[0026] (2), 500g of deionized water, 1.25g of sodium lauryl sulfate, 1.5g of potassium persulfate, 248g of styrene, 82g of acrylonitrile, 1.65g of glycidyl methacrylate were added to the pre-emulsification kettle and emulsified for 0.5h, Take 1250g of the emulsion in (1), raise the temperature to 80°C, start dropwise addition, and finish dropping in about 2 hours, raise the temperature to 85°C and keep it for 1 hour, then cool down to 40°C and discharge.

[0027] (3), raise the temperature of the grafted emulsion in (2) to 80°C, add calcium chloride s...

Embodiment 2

[0029] (1) Add 960g of deionized water to the reaction kettle, add 4g of sodium lauryl sulfate, 0.8g of 4,4'-azobis(4-cyanovaleric acid), 80g of butyl acrylate, ethyl methacrylate Glycol ester 0.24g, emulsified for 0.5h. The temperature was raised to 65° C., and after 0.5 h of reaction, a mixture of 720 g of butyl acrylate and 2.76 g of ethylene glycol methacrylate was added dropwise, continued for 2 h, and kept warm for 1 h.

[0030] (2) Add 1107g of deionized water, 0.4g of sodium lauryl sulfate, 0.1g of sodium dodecylbenzenesulfonate, 0.5g of potassium persulfate, 226g of styrene, 150g of acrylonitrile, methyl Emulsify 7.54g of glycidyl acrylate for 0.5h; take 1250g of the emulsion in step (1), raise the temperature to 80°C, start to add the pre-emulsion liquid dropwise, finish dropping in about 4h, raise the temperature to 90°C and keep it for 1h, then cool down to 40°C. material.

[0031] (3) Heat up the grafted emulsion in 2 to 80°C, add calcium chloride solution, stir...

Embodiment 3

[0033](1) Add 1440g of deionized water to the reactor, add 10g of sodium lauryl sulfate, 14g of alkylphenol polyoxyethylene ether OP, 2,2'-azobis(2-methylpropylamidine) disalt salt, 2,2'-azobis[N-(2-carboxyethyl)-2-methylpropionamidine] 4g each, after dissolving, add 160g of butyl acrylate and 3.2g of ethylene glycol methacrylate, Emulsify for 0.5h. The temperature was raised to 75° C., and after 0.5 h of reaction, a mixture of 640 g of butyl acrylate and 12.8 g of allyl methacrylate was added dropwise, continued for 3 h, and kept warm for 1 h.

[0034] (2) Add 580g of deionized water, 0.1g of sodium lauryl sulfate, 0.1g of potassium persulfate, 235g of styrene, 58g of acrylonitrile, and 14g of glycidyl methacrylate to emulsify for 0.5h in the pre-emulsification kettle. 1250g of the emulsion in (1), heated up to 80°C, dripped in about 2 hours, raised the temperature to 90°C for 1 hour, cooled to 40°C and discharged.

[0035] (3) Warm up the grafted emulsion in 2 to 80°C, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com