Preparation and application of a copper-zinc acrylate composite self-polishing antifouling resin

A technology of antifouling resin and copper acrylate, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of difficult formation of high relative molecular weight, unsatisfactory antifouling effect, slow hydrolysis rate, etc. problem, to achieve excellent antifouling effect, complete dehydration and complete reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

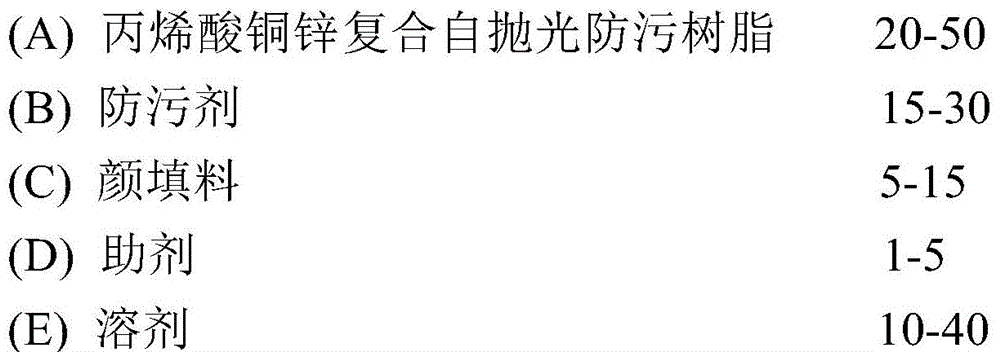

Method used

Image

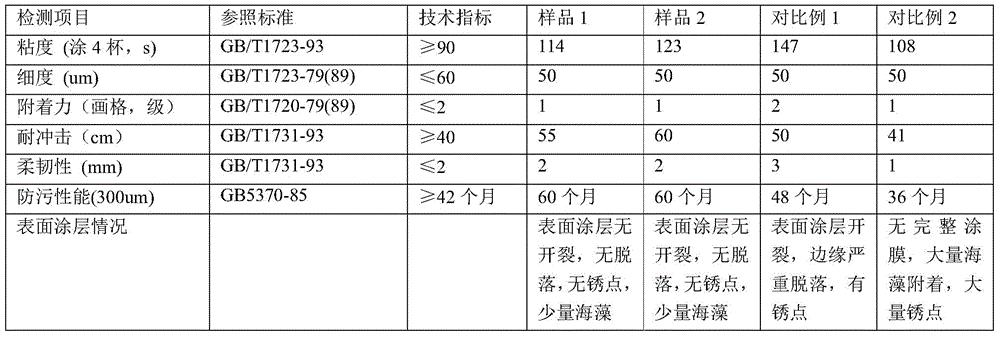

Examples

Embodiment 1

[0034] Synthesis of No. 1 Copper-Zinc Polyacrylate Resin

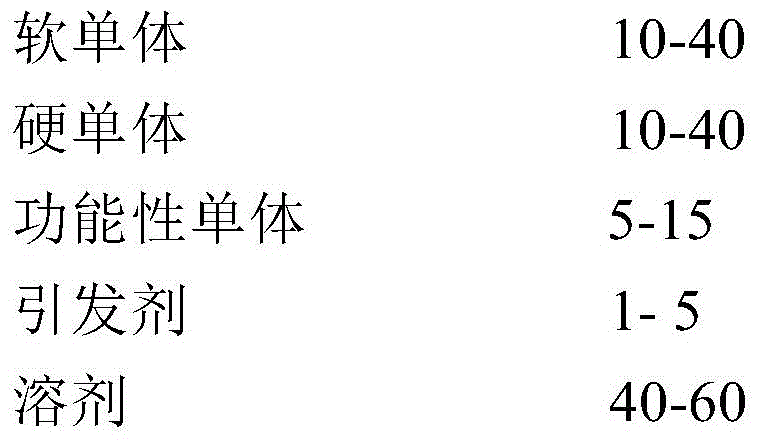

[0035] raw material

[0036] Acrylic acid prepolymer 50g, acrylic acid content is 5% (weight part), mass ratio is the mixed solution 20g of dimethylbenzene and n-butanol of 4:1, basic copper zinc benzoate compound (basic zinc benzoate and Basic copper benzoate is mixed according to the molar ratio of 1:1). Adopt the mode of basic copper-zinc benzoate compound feeding three times, according to equimolar charging ratio (acrylic acid and basic copper-zinc benzoate compound equimolar reaction), add basic copper-zinc benzoate total mass for the first time 1 / 2, react at 80°C for half an hour, add 1 / 4 of the total mass for the second time, react at 80°C for 1 hour, add 1 / 4 of the total mass for the third time, react at 90°C for 1 hour, heat up to 125°C for dehydration, A light blue transparent acrylic copper zinc resin was obtained.

Embodiment 2

[0038] Synthesis of No. 2 Copper-Zinc Polyacrylate Resin

[0039] raw material

[0040] Acrylic acid prepolymer 50g, acrylic acid content is 7% (weight part), mass ratio is the mixed solution 25g of xylene and butyl acetate of 4:1, basic copper zinc benzoate compound (basic zinc benzoate and Basic copper benzoate is mixed according to the molar ratio of 1:1). Adopt the mode of basic copper-zinc benzoate compound feeding three times, according to equimolar charging ratio (acrylic acid and basic copper-zinc benzoate compound equimolar reaction), add basic copper-zinc benzoate total mass for the first time 1 / 2, react at 80°C for half an hour, add 1 / 4 of the total mass for the second time, react at 80°C for 1 hour, add 1 / 4 of the total mass for the third time, react at 90°C for 1 hour, heat up to 125°C for dehydration, A light blue transparent acrylic copper zinc resin was obtained.

Embodiment 3

[0042] raw material

[0043] Acrylic acid prepolymer 50g, acrylic acid content is 5% (weight part), mass ratio is the mixed solution 20g of dimethylbenzene and n-butanol of 4:1, basic copper zinc benzoate compound (basic zinc benzoate and Basic copper benzoate is mixed according to the molar ratio of 1:2), adopts the mode of feeding three times of basic copper-zinc benzoate complex, according to equimolar feed ratio (acrylic acid and basic benzoic acid copper-zinc complex equimolar reaction), the first Add 1 / 2 of the total mass of the basic copper-zinc benzoate complex once, react at 80 degrees for half an hour, add 1 / 4 of the total mass for the second time, react at 80 degrees for 1 hour, and add 1 / 4 of the total mass for the third time 4. React at 90°C for 1 hour, heat up to 125°C for dehydration, and obtain light blue transparent acrylic copper-zinc resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com