High temperature resistant organic silicon resin emulsion paint

A high-temperature-resistant resin and silicone technology, applied in the field of resin paint, can solve the problems of poor mechanical properties, unsatisfactory, low salt spray resistance, etc., and achieve the effect of excellent salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

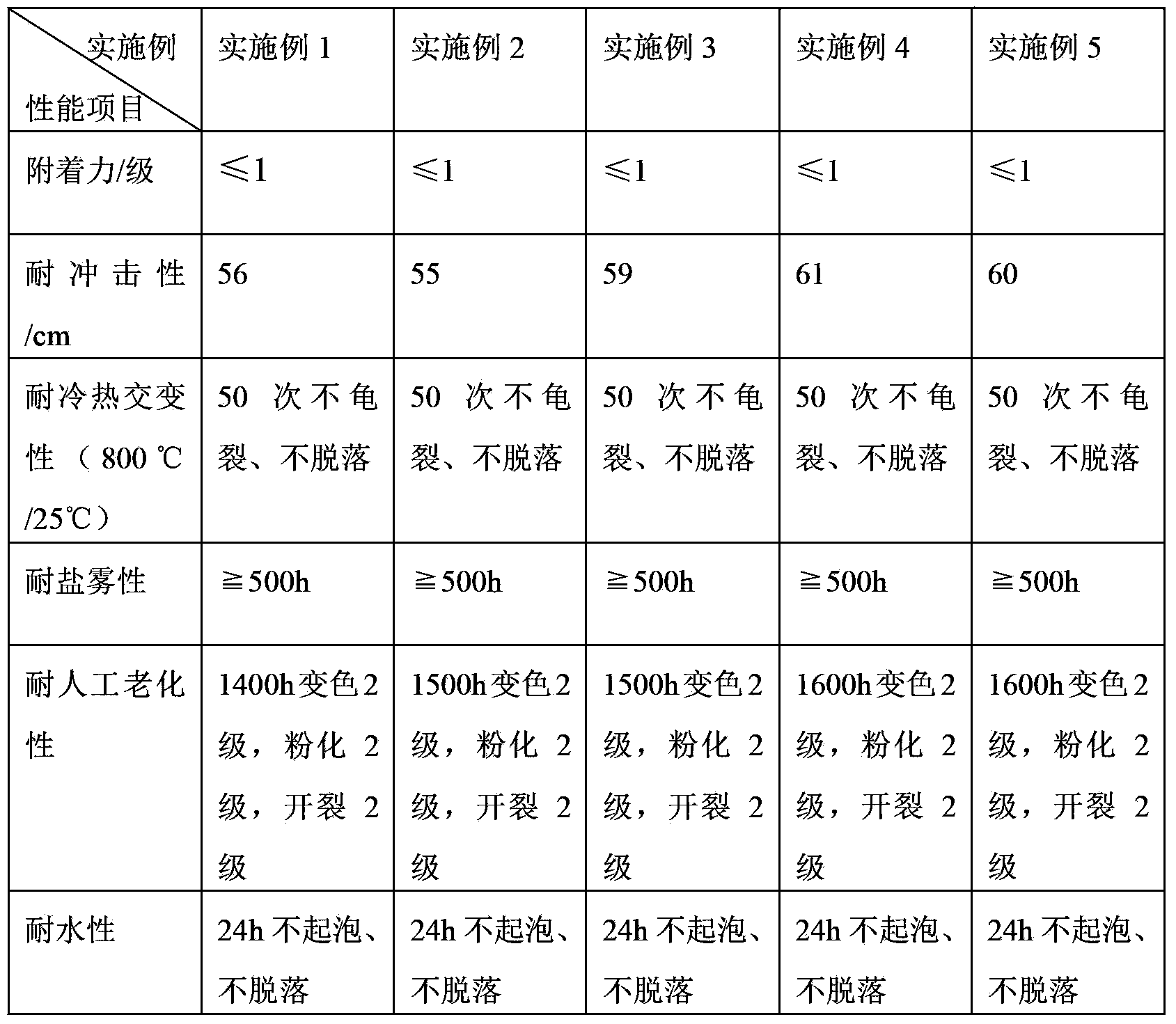

Examples

Embodiment 1

[0018] A kind of organosilicon high temperature resistant resin coating, its components are composed of the following components by weight: 40 parts of silicone resin, 15 parts of epoxy resin, 10 parts of titanium dioxide, 2.8 parts of additives, 10 parts of glass powder, ceramic powder 7 parts, 11 parts of mica powder, 3 parts of asbestos powder, 1.5 parts of zinc phosphate;

[0019] Wherein, the auxiliary agent includes: the weight ratio of fumed silica, polyethylene glycol and KH550 silane coupling agent is 1:2:3.

[0020] The preparation steps of the above-mentioned organosilicon high temperature resistant resin coating include:

[0021] (1) Weigh the corresponding raw material components according to the above parts by weight;

[0022] (2) Add silicone resin and epoxy acrylic resin into the stock pot, stir and mix evenly;

[0023] (3) Then add coloring pigment defoamer, wetting agent, film aid in turn in the material preparation pot, after mixing evenly, add anti-sedime...

Embodiment 2

[0025] A kind of organosilicon high temperature resistant resin coating, its components are composed of the following components by weight: 25 parts of silicone resin, 10 parts of epoxy resin, 15 parts of cadmium red, 3.8 parts of additives, 18 parts of glass powder, ceramic powder 4 parts, 11 parts of mica powder, 1.5 parts of zinc phosphate; wherein, the auxiliary agent includes: the weight ratio of fumed silica, polyethylene glycol and KH550 silane coupling agent is 1:2:3.

[0026] The preparation steps of the above-mentioned organosilicon high temperature resistant resin coating include:

[0027] (1) Weigh the corresponding raw material components according to the above parts by weight;

[0028] (2) Add silicone resin and epoxy acrylic resin into the stock pot, stir and mix evenly;

[0029] (3) Then add coloring pigment defoamer, wetting agent, film aid in turn in the material preparation pot, after mixing evenly, add anti-sedimentation agent, dispersant, coloring pigment...

Embodiment 3

[0031] A kind of organosilicon high temperature resistant resin coating, its component is made up of the following components by weight: 35 parts of organosilicon resin, 12 parts of epoxy resin, 14 parts of ferrochrome black, 3.8 parts of auxiliary agent, 17 parts of glass powder, ceramic 18 parts of powder, 2.0 parts of zinc phosphate;

[0032] Wherein, the auxiliary agent includes: the weight ratio of fumed silica, polyethylene glycol and KH550 silane coupling agent is 1:2:3.

[0033] The preparation steps of the above-mentioned organosilicon high temperature resistant resin coating include:

[0034] (1) Weigh the corresponding raw material components according to the above parts by weight;

[0035] (2) Add silicone resin and epoxy acrylic resin into the stock pot, stir and mix evenly;

[0036] (3) Then add coloring pigment defoamer, wetting agent, film aid in turn in the material preparation pot, after mixing evenly, add anti-sedimentation agent, dispersant, coloring pigm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com