Fireproof coating and preparation method thereof

A technology of fireproof coatings and raw materials, applied in the field of coatings, can solve the problems of impact resistance, artificial aging resistance, poor adhesion, and affecting service life, etc., and achieve the effects of low production cost, strong adhesion, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

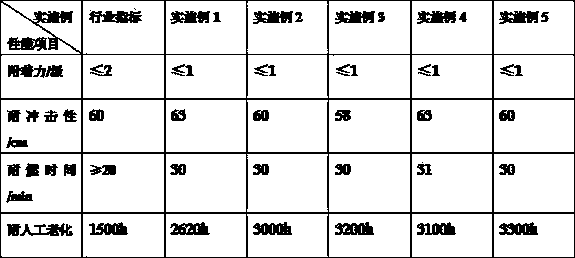

Examples

Embodiment 1

[0016] A kind of fireproof coating, its component is made up of following composition by weight percentage: 80% of A component and 20% of B component; Said A component comprises following component by weight: 30 parts of ethylene-vinyl acetate Ester copolymer, 25 parts of colored pigments, 1 part of auxiliary agent, 0.4 part of mixed solvent; auxiliary agent includes wetting agent, anti-sedimentation agent and defoamer; mixed solvent includes propylene glycol and butyl acetate; component B is by weight It includes the following components: 15 parts of cobalt naphthenate, 10 parts of melamine pyrophosphate, 20 parts of propylene glycol, and 15 parts of talcum powder. Additives include wetting agent, anti-settling agent and defoamer in a weight ratio of 1:3:2. The volume ratio of propylene glycol to butyl acetate in the mixed solvent is 3:2. The coloring pigment is titanium dioxide.

[0017] The preparation method of described fireproof coating, comprises the following steps: ...

Embodiment 2

[0023] A kind of fireproof coating, its component is made up of following composition by weight percentage: 90% of A component and 10% of B component; Described A component comprises following component by weight: 50 parts of ethylene-vinyl acetate Ester copolymer, 20 parts of colored pigments, 8 parts of auxiliary agent, 0.6 part of mixed solvent; auxiliary agent includes wetting agent, anti-settling agent and defoamer; mixed solvent includes propylene glycol and butyl acetate; described B component by weight The parts include the following components: 20 parts of cobalt naphthenate, 20 parts of melamine pyrophosphate, 30 parts of propylene glycol, and 20 parts of talcum powder. Additives include wetting agent, anti-settling agent and defoamer in a weight ratio of 1:3:2. The volume ratio of propylene glycol to butyl acetate in the mixed solvent is 3:2. The coloring pigment is carbon black.

[0024] The preparation method of fireproof coating comprises the following steps: ...

Embodiment 3

[0029] A kind of fireproof coating, its component is made up of following composition by weight percentage: 85% of A component and 15% of B component; Said A component comprises following component by weight: 40 parts of ethylene-vinyl acetate Ester copolymer, 22 parts of colored pigments, 5 parts of auxiliary agent, 0.5 part of mixed solvent; auxiliary agent includes wetting agent, anti-sedimentation agent and defoamer; mixed solvent includes propylene glycol and butyl acetate; component B is by weight It includes the following components: 17 parts of cobalt naphthenate, 15 parts of melamine pyrophosphate, 25 parts of propylene glycol, and 17 parts of talcum powder. Additives include wetting agent, anti-settling agent and defoamer in a weight ratio of 1:3:2. The volume ratio of propylene glycol to butyl acetate in the mixed solvent is 3:2. The coloring pigments are phthalocyanine blue and iron oxide red.

[0030] The preparation method of fireproof coating comprises the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com