High-efficiency environment-friendly antibacterial mildew-proof paint containing nano film-forming agent and preparation method thereof

An antibacterial, antifungal, and film-forming agent technology, which is applied in the field of architectural coatings, can solve the problems of low adhesion between coatings and cement bases, complex production and preparation processes, poor strength, and poor weather resistance, and achieve excellent heat insulation effects, Good surface expansion adsorption, enhanced corrosion resistance and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

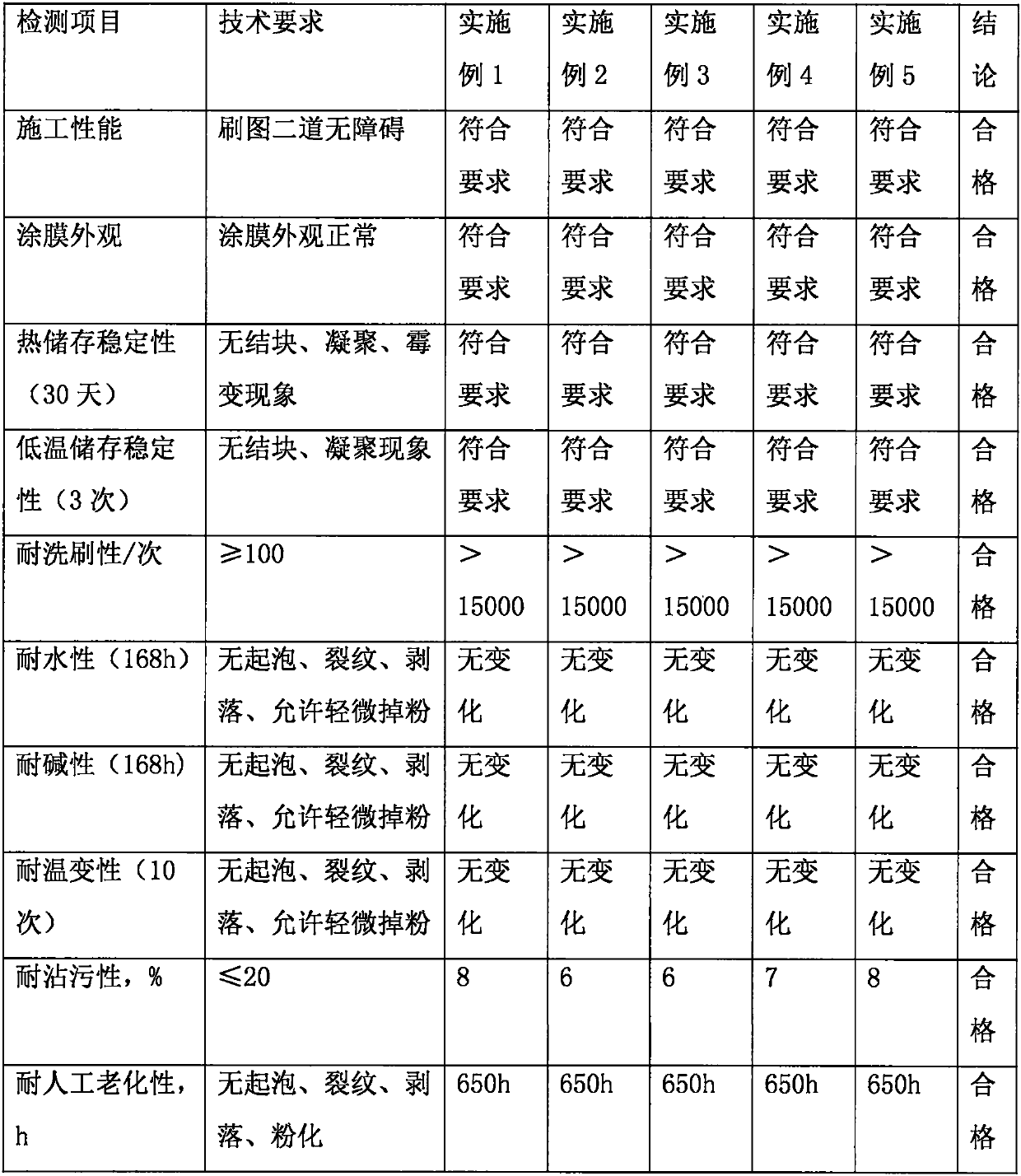

Embodiment 1

[0024] (1) Weigh 45 grams of heavy calcium powder, 35 grams of gray calcium powder, 25 grams of white Portland cement, 18 grams of hollow microspheres, 8 grams of nano-silicon dioxide, 8 grams of rutile titanium dioxide, and 8 grams of dicalcium silicate , 8 grams of sepiolite powder, 8 grams of sodium oxalate, 7 grams of talc powder, 3 grams of tourmaline powder, 3 grams of attapulgite clay, 2 grams of sodium bentonite, 1.8 grams of polyvinyl alcohol powder, 1.8 grams of redispersible latex powder , 2 grams of lithium sulfate, 1 gram of calcium lignosulfonate, 0.5 gram of hydroxypropyl methylcellulose, 0.25 gram of wood fiber, 0.3 gram of organosilicon polyether composite defoamer;

[0025] (2) The raw materials are heavy calcium powder, gray calcium powder, white Portland cement, rutile titanium dioxide, dicalcium silicate, sepiolite powder, sodium oxalate, talcum powder, tourmaline powder, attapulgite clay, polyvinyl alcohol Add the powder into the grinder and grind to 2000...

Embodiment 2

[0029] (1) Weigh 40 grams of heavy calcium powder, 30 grams of gray calcium powder, 20 grams of white Portland cement, 15 grams of hollow microspheres, 6 grams of nano-silicon dioxide, 6 grams of rutile titanium dioxide, and 5 grams of dicalcium silicate , 5 grams of sepiolite powder, 5 grams of sodium oxalate, 5 grams of talc powder, 1 gram of tourmaline powder, 1 gram of attapulgite clay, 1 gram of sodium bentonite, 1.6 grams of polyvinyl alcohol powder, 1.6 grams of redispersible latex powder , 1 gram of lithium sulfate, 0.5 gram of calcium lignosulfonate, 0.3 gram of hydroxypropyl methylcellulose, 0.2 gram of wood fiber, 0.1 gram of organosilicon polyether composite defoamer;

[0030] (2) The raw materials are heavy calcium powder, gray calcium powder, white Portland cement, rutile titanium dioxide, dicalcium silicate, sepiolite powder, sodium oxalate, talcum powder, tourmaline powder, attapulgite clay, polyvinyl alcohol Add the powder into the grinder and grind to 2000 me...

Embodiment 3

[0034] (1) 42 grams of weighing calcium powder, 32 grams of gray calcium powder, 22 grams of white Portland cement, 16 grams of hollow microspheres, 7 grams of nano silicon dioxide, 7 grams of rutile titanium dioxide, 6 grams of dicalcium silicate, 6 grams of sepiolite powder, 6 grams of sodium oxalate, 6 grams of talc powder, 2 grams of tourmaline powder, 2 grams of attapulgite clay, 1 gram of sodium bentonite, 1.7 grams of polyvinyl alcohol powder, 1.7 grams of redispersible latex powder, Lithium sulfate 1 g, calcium lignosulfonate 0.8 g, hydroxypropyl methylcellulose 0.4 g, wood fiber 0.2 g, silicone polyether composite defoamer 0.2 g;

[0035] (2) The raw materials are heavy calcium powder, gray calcium powder, white Portland cement, rutile titanium dioxide, dicalcium silicate, sepiolite powder, sodium oxalate, talcum powder, tourmaline powder, attapulgite clay, polyvinyl alcohol Add the powder into the grinder and grind to 2500 mesh;

[0036] (3) Add sodium bentonite, li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com