Method for preparing organic-solvent-resistant ultrafiltration membrane, prepared ultrafiltration membrane and application of ultrafiltration membrane

An organic solvent-resistant, ultrafiltration membrane technology, applied in the field of membrane separation, can solve the problems of limited application scope and easy swelling, and achieve the effects of shortening membrane preparation time, improving mass transfer speed, and enhancing solvent resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

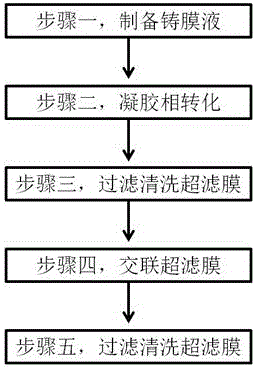

Method used

Image

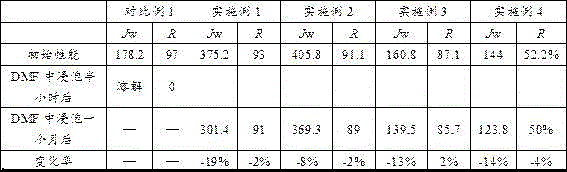

Examples

Embodiment 1

[0040] After uniformly mixing 2.5g of polyimide and 10g of N,N-dimethylformamide, mechanically stir at 55°C for 5h to fully dissolve, and then use a high-speed centrifuge at room temperature at 1500r / min High-speed centrifugal defoaming for 15 minutes to obtain casting solution;

[0041] Use a flat-plate scraping machine to evenly scrape the defoamed casting solution on the polyester non-woven fabric, control the height of the scraper, scrape it into a film at room temperature, and form a coating with a thickness of 150um; The coating was left to evaporate in the air at room temperature for 20 seconds, and then immersed in deionized water at 30°C for 10 minutes. At this time, the high molecular polymer in the casting solution undergoes a gel phase transition and precipitates on the surface of the non-woven fabric to form a film;

[0042] Then take out the membrane, wash the residual solution on the surface of the membrane with deionized water, then filter and wash with pure is...

Embodiment 2

[0052] Mix 2.5g of polyimide, 0.14g of polyethylene glycol 400 and 11.25g of N,N-dimethylformamide evenly, stir mechanically at 55°C for 5h to fully dissolve, and then use high-speed centrifugation Centrifuge and defoam at a high speed at 1500r / min for 15min at room temperature to obtain the casting solution;

[0053] Use a flat-plate scraping machine to evenly scrape the defoamed casting solution on the polyester non-woven fabric, control the height of the scraper to scrape it into a film at room temperature, and form a coating with a thickness of 150um; The layer was left to evaporate in the air at room temperature for 5 seconds, and then immersed in deionized water at 30°C for 10 minutes. At this time, the high molecular polymer in the casting solution undergoes gel phase transformation and precipitates on the surface of the non-woven fabric to form a film;

[0054] Then take out the membrane, rinse the residual solution on the surface of the membrane with deionized water, ...

Embodiment 3

[0059] After uniformly mixing 4.5g of polyimide and 16g of N,N-dimethylformamide, mechanically stir at 55°C for 6h to fully dissolve, and then use a high-speed centrifuge at room temperature at 1500r / min High-speed centrifugal defoaming for 30min;

[0060] Utilize a flat-plate scraping machine to evenly scrape the prepared casting solution on the polyester non-woven fabric, control the height of the scraper to scrape it into a film at room temperature, and form a coating with a thickness of 120um; Leave to evaporate in air at room temperature for 20 seconds, and then immerse in deionized water at 30°C for 30 minutes. At this time, the high molecular polymer in the casting solution undergoes gel phase transformation and precipitates on the surface of the non-woven fabric to form a film;

[0061] Then take out the membrane, rinse the residual solution on the surface of the membrane with deionized water, then filter and wash with pure isopropanol at room temperature and 0.1MPa fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com