High-yield phosphorous-doped porous carbon material and preparation method thereof

A porous carbon material, phosphorus doping technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of cumbersome preparation process, large energy consumption, etc., and achieve huge application value, high specific surface area, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

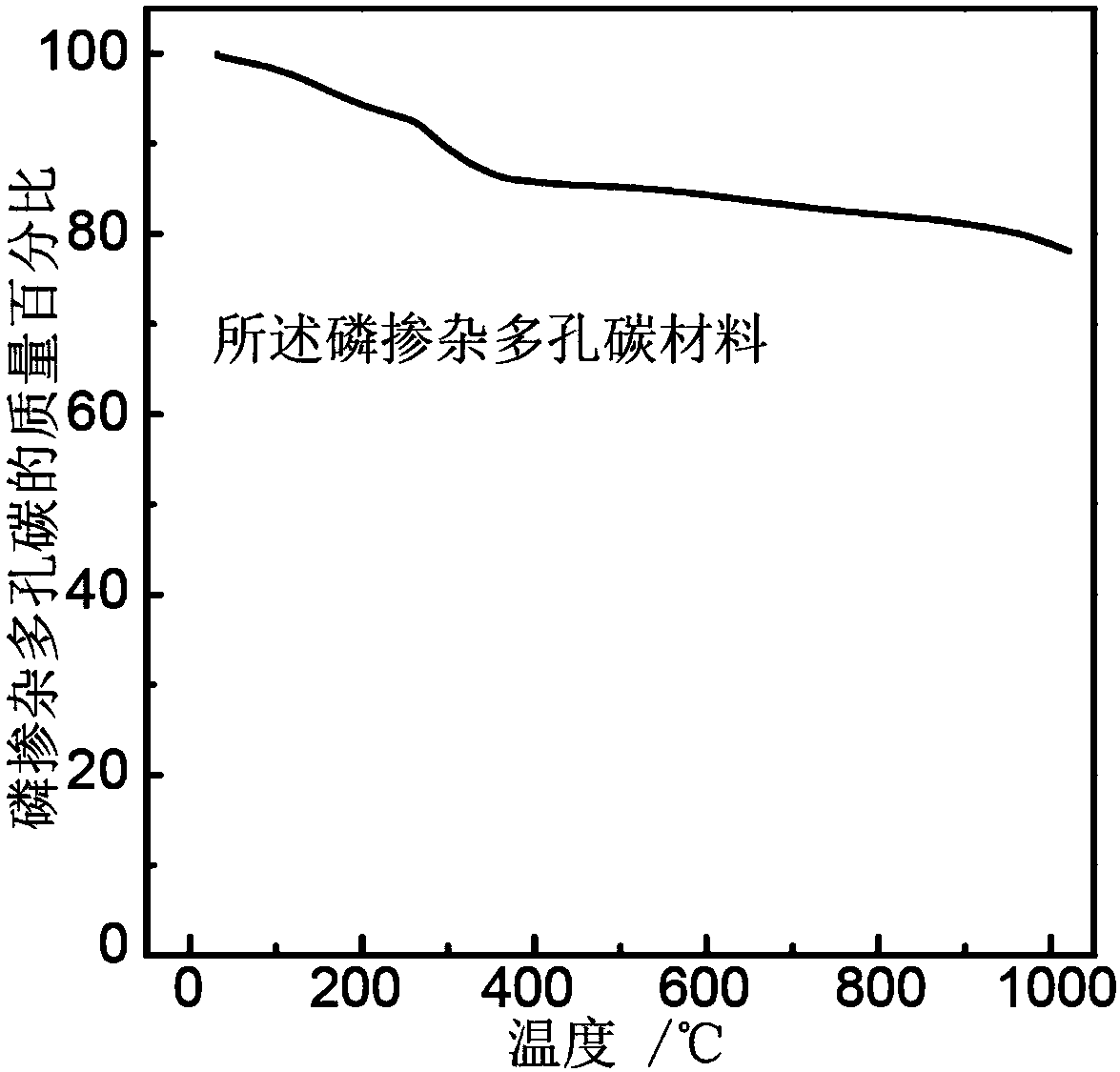

[0037] Put 2g of potassium phytate into a tube furnace, and perform high-temperature calcination under a nitrogen atmosphere. The heating rate is 3°C / min, the calcination temperature is 800°C, and the calcination time is 1h. Cool naturally to room temperature to obtain a precursor; The precursor was treated with 1 mole per liter of hydrochloric acid at room temperature for 18 hours, then washed with deionized water, centrifuged several times until neutral, and the precipitate was collected to obtain wet phosphorus-doped porous carbon; the wet phosphorus-doped porous carbon was Under vacuum conditions (vacuum degree less than 5 Pa), drying at 80° C. for 12 hours to obtain the phosphorus-doped porous carbon material provided by the present invention.

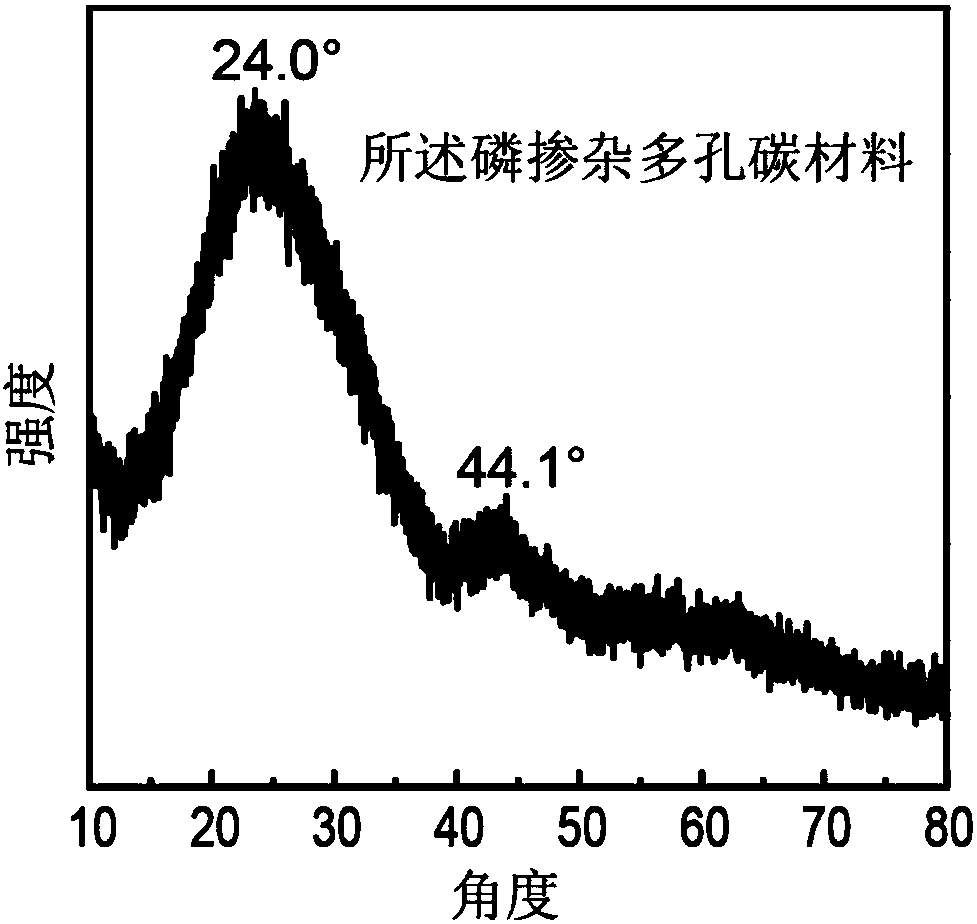

[0038] figure 1 is the X-ray powder diffraction curve of the phosphorus-doped porous carbon material prepared in Example 1. It can be seen from the figure that the phosphorus-doped porous carbon material prepared in Example 1 is g...

Embodiment 2

[0044] Prepare phosphorus-doped porous carbon material basically according to the same method as Example 1, the difference is that sodium phytate is used instead of potassium phytate, and the obtained material has the same composition as the material obtained in Example 1; its phosphorus-doped porous carbon produces The ratio is comparable to the material obtained in Example 1.

Embodiment 3

[0046] Prepare phosphorus-doped porous carbon material basically according to the same method as Example 1, the difference is that the high-temperature calcination atmosphere is changed from nitrogen to argon, and the obtained material has the same composition as that obtained in Example 1; its phosphorus-doped porous carbon material The carbon yield was comparable to the material obtained in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com