Multi-layer variable geometric volute device

A volute and geometry technology, applied in the field of multi-layer variable geometry volute devices, can solve the problems of high negative pressure difference between the intake and exhaust of the engine, affecting the performance of the engine, and high pumping loss, so as to increase the boosting ratio and simple structure , good inheritance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

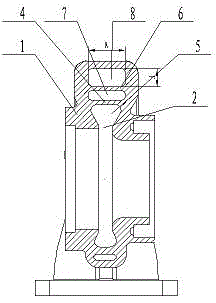

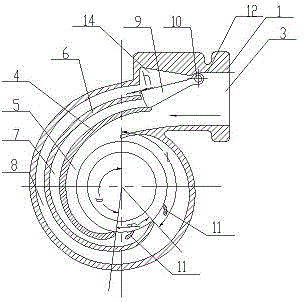

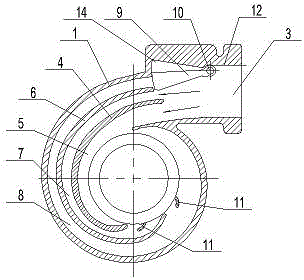

[0058] Example 1, such as figure 1 , figure 2 As shown, a multi-layer variable geometry volute device includes a turbine volute 1, which is provided with a volute inlet flow passage and a bladeless nozzle 2, and the turbine volute 1 is provided with and The volute air inlet 3 connected with the volute air inlet flow channel;

[0059] A first aerodynamic partition 4 is provided in the volute air inlet flow path, and the first aerodynamic partition 4 divides the volute air inlet flow path into a volute air inlet inner flow path 5 and a volute air inlet outer flow path;

[0060] A second aerodynamic partition 6 is provided in the volute air inlet outer flow path, and the second aerodynamic partition 6 divides the volute air inlet outer flow path into a first branch flow path 7 and a second branch flow path 8;

[0061] The volute air intake inner flow passage 5 is a normally open intake flow passage;

[0062] In the volute air inlet flow path, an air inlet regulating valve 9 for controll...

Embodiment 2

[0079] Example 2, such as Figure 5 As shown, in Embodiment 1, the cross-sectional shape of the air intake adjusting valve 9 may also be a rectangular structure, and the air intake adjusting valve shaft 10 is arranged on the second pneumatic partition 6 at the end close to the end of the air inlet 3. Department location.

[0080] The ratio of the distance between the center position of the intake control valve shaft 10 and the end of the intake control valve 9 near the first pneumatic partition 4 to the center of the intake control valve shaft 10 to the distance between the intake control valve 9 and the inner wall 12 of the volute The range is 1 / 4~1 / 2.

[0081] In order to ensure that the air intake regulating valve 9 achieves a good sealing fit with the inner wall 12 of the volute and the first pneumatic partition 4, both ends of the air intake regulating valve 9 are inclined surface structures. The partition plate 4 is respectively provided with mating surfaces that are matched...

Embodiment 3

[0085] Example 3, such as Figure 8 , Picture 9 As shown, in the above-mentioned embodiment 2, the intake regulating valve shaft 10 may also be arranged at an end of the intake regulating valve 9 close to the first pneumatic partition 4.

[0086] The end of the intake control valve 9 away from the intake control valve shaft 10 has a slope structure, and the inner wall 12 of the volute and the second pneumatic partition 6 are respectively provided with mating surfaces that cooperate with the intake control valve 9.

[0087] According to the position of the intake control valve shaft, the ratio of the intake area angle β of the first branch flow passage 7 and the intake area angle γ of the second branch flow passage 8 ranges from 6:1 to 2:1. Make any adjustments according to the situation.

[0088] The ratio of the cross-sectional area of the second branch flow channel 8 to the cross-sectional area of the first branch flow channel 7 ranges from 1 / 4 to 1 / 2.

[0089] Two to three gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com