Pressurization equipment for construction machinery cab

A technology for pressurization equipment and construction machinery, which is applied in air handling equipment, transportation and packaging, vehicle parts, etc. Compact structure and the effect of reducing indoor noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

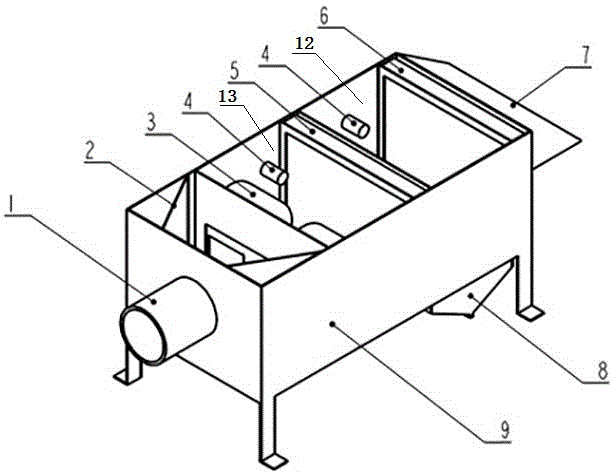

[0012] Below in conjunction with accompanying drawing example the present invention is described in further detail:

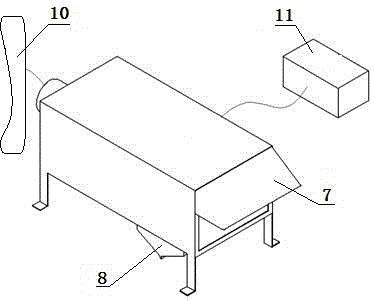

[0013] like figure 1 and figure 2 The pressurization equipment for construction machinery cabs shown includes a filter, a housing 9 provided with an air inlet and an air outlet pipe 1, and an air intake rain shield is welded above the outer side of the air inlet of the housing 9 7; The filter of this embodiment includes a primary filter 6 placed at the air inlet in the housing 9 and a secondary filter 5 placed behind the primary filter 6, the secondary filter 5 connects the housing 9 The inner space of the first chamber is divided into a first chamber 12 and a second chamber 13; an automatic dust remover 8 is installed at the bottom of the first chamber 12, and the automatic dust remover 8 has a dust discharge hood with a dust discharge port at the bottom, A rubber sewage duckbill valve is installed on the dust outlet; a blower 3 is installed in the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com