Power control mechanism of gas engine

A gas engine and power control technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as large engine power and speed fluctuation range, front-end system turbocharger surge, and affecting the normal operation of the turbocharger, etc. , to achieve the effect of small fluctuation range of speed and power, reduce purchase cost, and avoid surge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

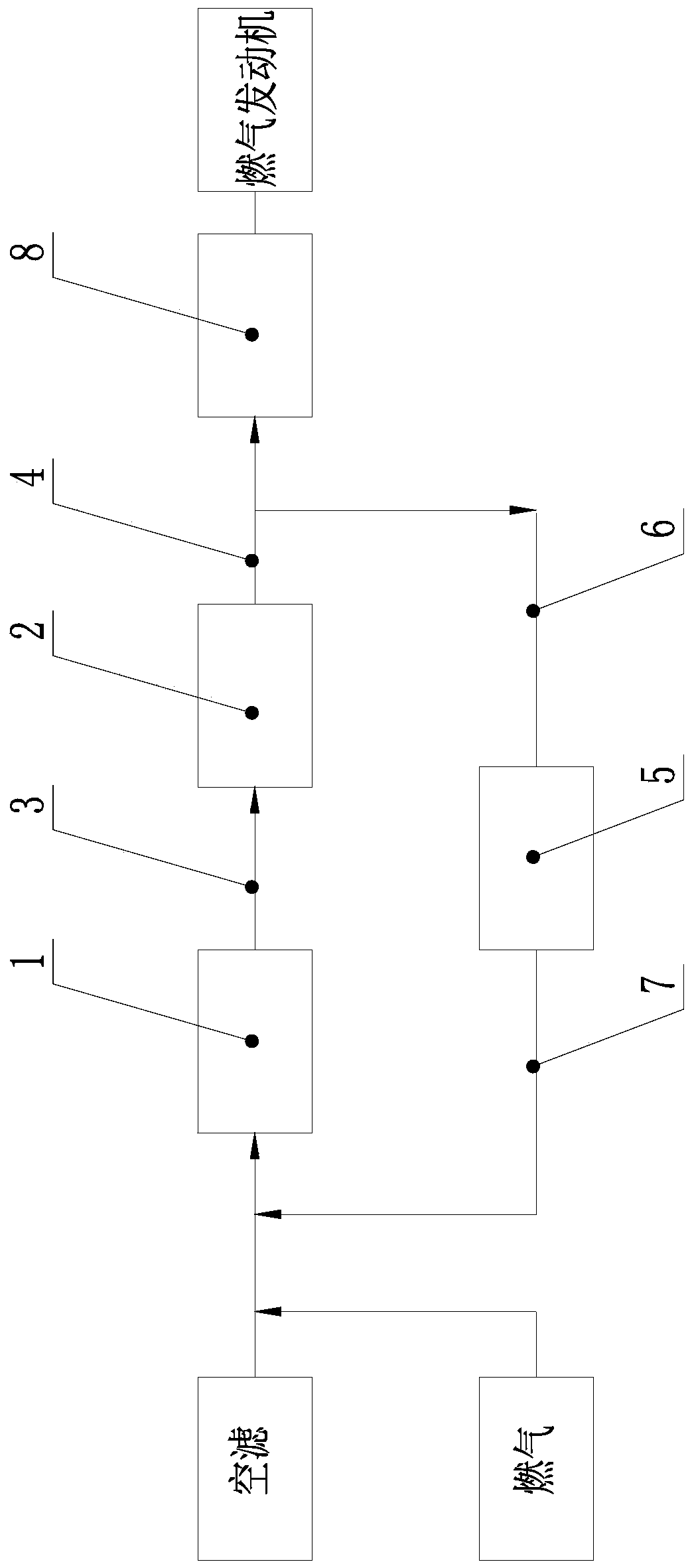

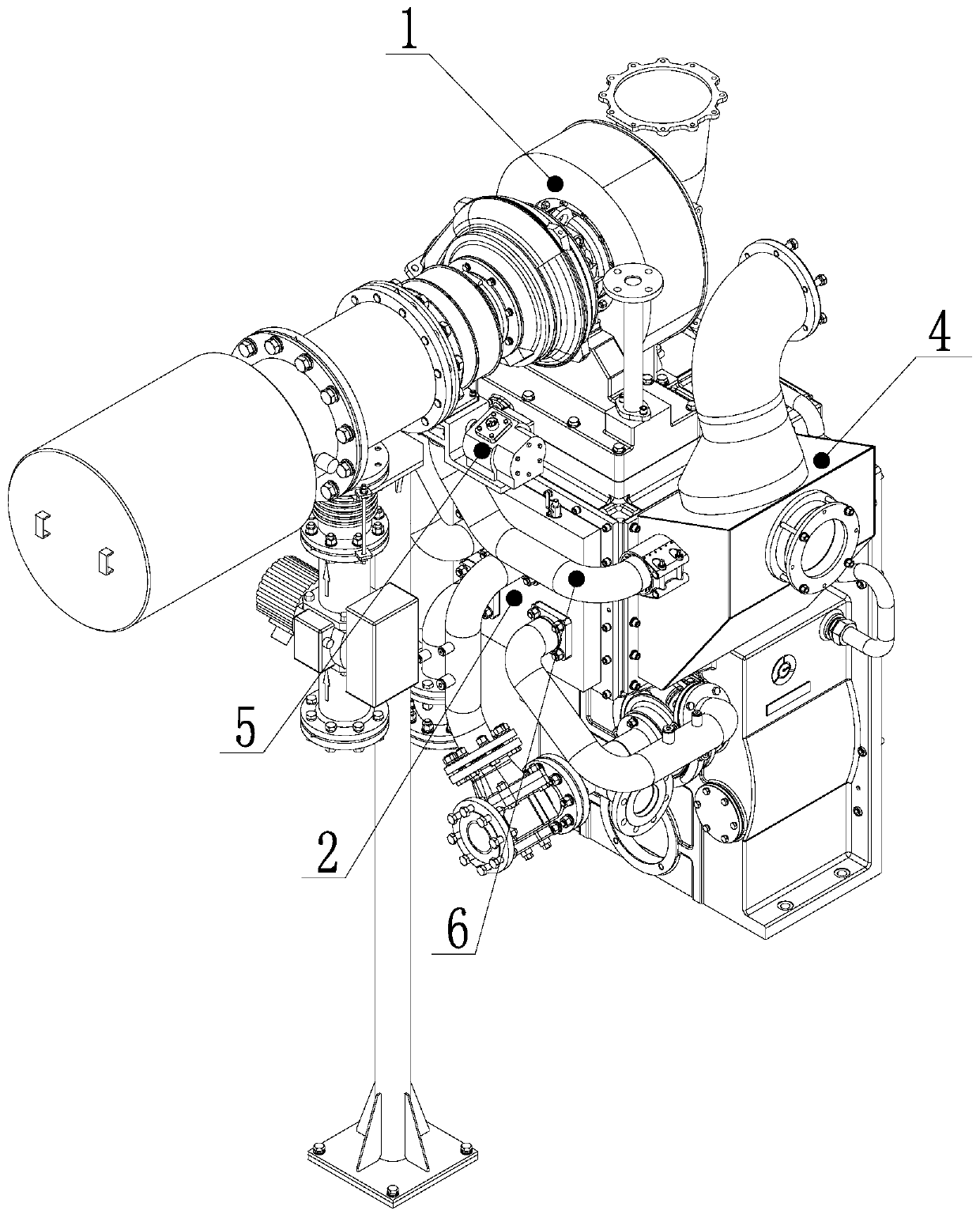

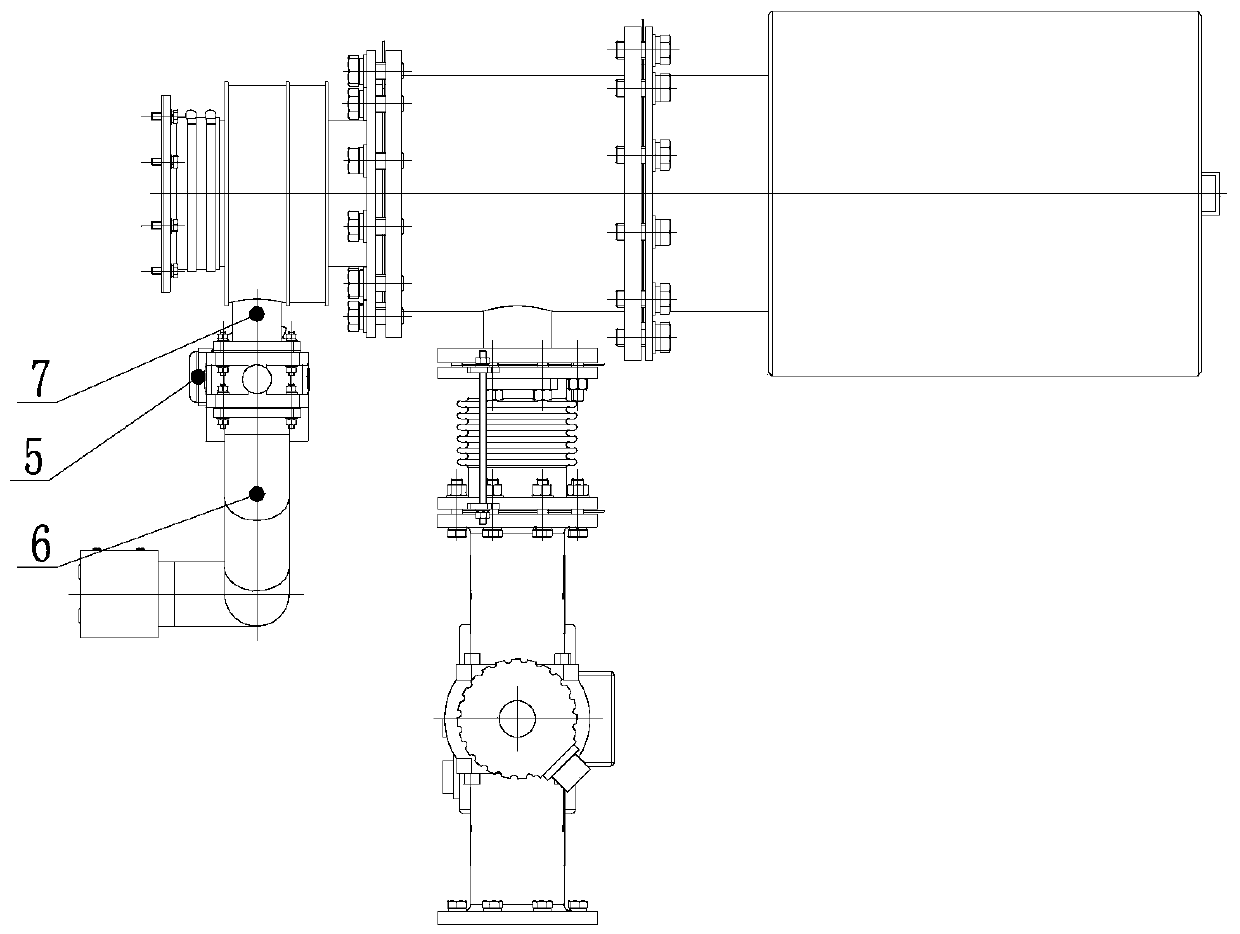

[0019] see Figure 1 to Figure 3 , is a specific embodiment of a power control mechanism of a gas engine. The power control mechanism of the gas engine includes a supercharger 1 and an intercooler 2, both of which are conventional equipment in the field of gas engines. The mixed gas outlet of the supercharger 1 is connected to the air inlet of the intercooler 2 through the first gas path 3. The first gas path adopts conventional high-temperature-resistant and high-pressure pipelines in the field of gas engines, and adopts conventional connection methods. Alternatively, other air path forms can also be used, such as the integrated cavity of the front-end system, connecting the mixed gas outlet port of the supercharger and the air inlet port of the intercooler. The air outlet end of the intercooler 2 is connected to the second gas circuit 4, which is used to provide pressurized and cooled air and gas mixture to the cylinder of the gas engine. The second gas circuit adopts a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com