Hybrid flow variable spiral case

A hybrid and volute technology, applied to engine components, machines/engines, internal combustion piston engines, etc., can solve the problems of high negative pressure difference between the intake and exhaust of the engine, affecting engine performance, high pumping loss, etc., to achieve increased boost ratio, easy control method, and good inheritance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

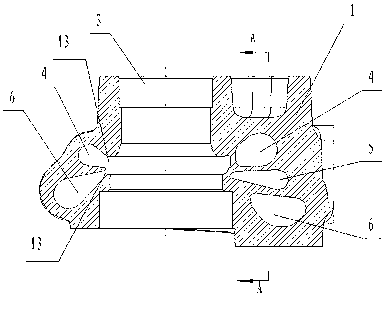

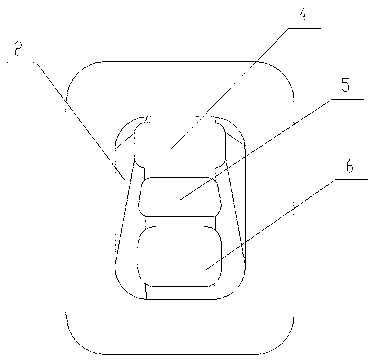

[0039] Example 1, such as figure 1 , figure 2 , image 3 As shown, a hybrid variable flow volute includes a turbine volute 1, a volute inlet flow passage and a volute nozzle ring 13 are arranged in the turbine volute 1, and a volute is provided at one end of the volute inlet flow passage Shell air inlet 2, the other end is provided with volute air outlet 3.

[0040] The volute air intake channel is separated into three channels arranged up and down through the partition: the first air intake channel 4, the second air intake channel 5 and the third air intake channel 6, the first air intake channel 4, the second air intake channel The air passage 5 and the third air intake passage 6 communicate with the air inlet 2 of the volute respectively.

[0041] The first air intake channel 4 is a normally open air intake channel; the first air intake channel 4 realizes the full-circle air intake of 0-360 degrees in the circumferential direction;

[0042] The air intake area angle α ...

Embodiment 2

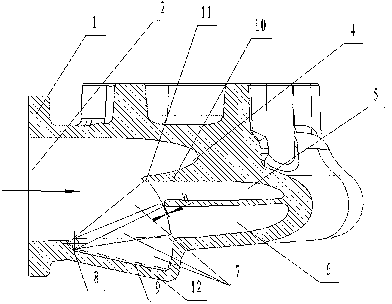

[0053] Example 2, such as Figure 6 , Figure 7 , Figure 8 As shown, this embodiment is another improvement on the basis of Embodiment 1, a hybrid variable flow volute, including a turbine volute 1, and the volute inlet flow passage is arranged inside the turbine volute 1 .

[0054] One end of the volute air intake channel is provided with a volute air inlet 2 and the other end is provided with a volute air outlet 3 .

[0055] The volute air intake channel includes three working channels: the first air intake channel 4, the second air intake channel 5 and the third air intake channel 6, the first air intake channel 4, the second air intake channel 5 and the third air intake channel The air passages 6 communicate with the air inlets 2 of the volute respectively.

[0056] The second air intake channel 5 and the first air intake channel 4 are arranged vertically; the third air intake channel 6 and the second air intake channel 5 are arranged side by side.

[0057] A pluralit...

Embodiment 3

[0063] Embodiment 3, above-mentioned embodiment 1 and embodiment 2 are adapted to constant pressure supercharging engine, as Figure 11 As shown, by combining two identical structures (two sets of flow passages) designed in embodiment 1 and embodiment 2 in a certain way (each set of flow passages corresponds to one engine exhaust manifold flow passage) to adapt to For the pulse supercharged engine, there are two volute air inlets designed at this time.

[0064] The design of the volute inlet flow channel is not limited to the above-mentioned three embodiments where the volute inlet flow channel is divided into three flow channels: the first air intake channel, the second air intake channel and the third air intake channel. For special requirements, the second air intake channel is divided into several air intake channel branches, and the third air intake channel is divided into several air intake channel branches. According to the arrangement of the two flow passage structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com