Tidal current energy water turbine runner and its water turbine

A water turbine and tidal current energy technology, which is applied in the direction of machines/engines, mechanical equipment, hydropower, etc., can solve problems such as large-scale development, and achieve the effects of increasing available energy, high energy utilization rate, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

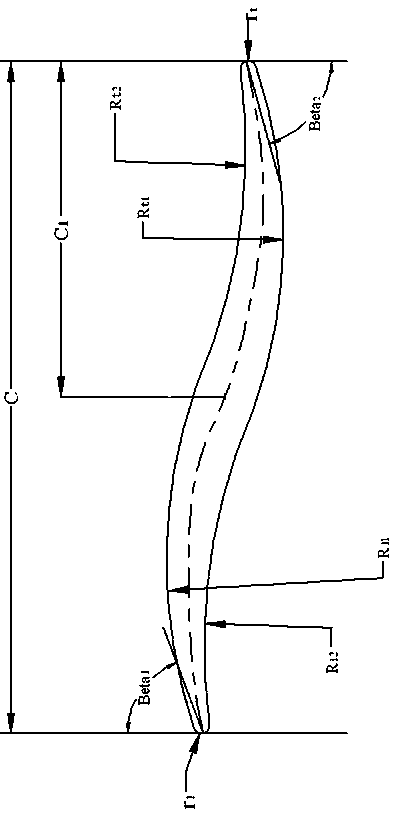

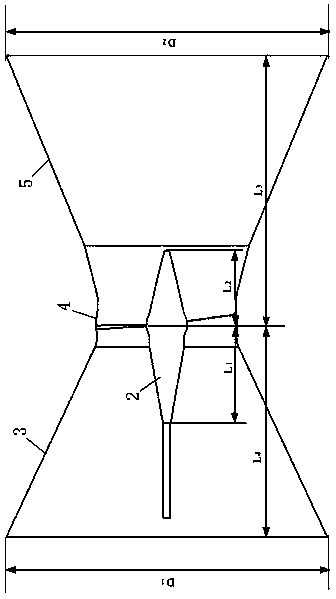

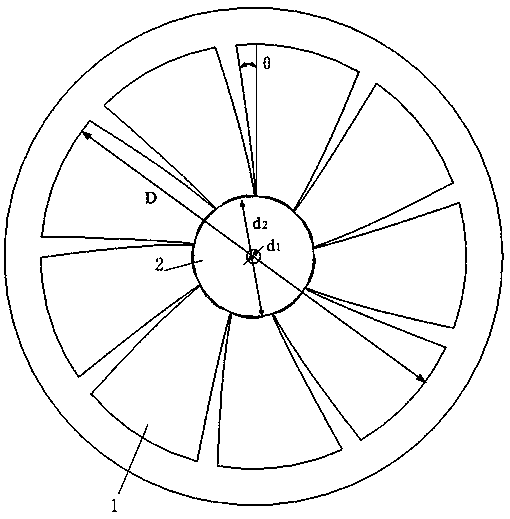

[0039] In this embodiment, the diameter D of the runner is 1483mm. The section of the runner blade is a hyperbolic airfoil composed of the first airfoil and the second airfoil. At the runner diameter D, the chord length C of the blade airfoil is 0.3D, and the leading edge radius of the airfoil is r 1 is 0.004D, the airfoil trailing edge radius r t is 0.004D, the radius R of the blade back profile of the first airfoil where the leading edge of the airfoil is located 11 is 0.2D, and the radius R of the leaf pot shape line 12 is 0.25D, the blade back profile radius R of the second airfoil part where the trailing edge of the airfoil is located t1 is 0.2D, and the radius R of the leaf pot shape line t2 is 0.25D, the placement angle Beta of the first airfoil of the blade 1 is 68°, the placement angle Beta of the second airfoil 2 is 70°. The airfoil chord length C of the second airfoil part 1 is 0.15D.

[0040] Nine pieces of blades 1 are arranged on the runner, and the cross...

Embodiment 2

[0045] In this embodiment, the diameter D of the runner is 1483mm. The section of the runner blade is a hyperbolic airfoil composed of the first airfoil and the second airfoil. At the runner diameter D, the chord length C of the blade airfoil is 0.35D, and the leading edge radius of the airfoil is r 1 is 0.005D, the airfoil trailing edge radius r t is 0.005D, the radius R of the blade back profile of the first airfoil where the leading edge of the airfoil is located 11 is 0.3D, and the radius R of the leaf pot shape line 12 is 0.35D, the blade back profile radius R of the second airfoil where the trailing edge of the airfoil is located t1 is 0.3D, and the radius R of the leaf pot shape line t2 is 0.35D, the placement angle Beta of the first airfoil of the blade 1 is 71°, the placement angle Beta of the second airfoil 2 is 74°. The airfoil chord length C of the second airfoil part 1 is 0.175D.

[0046] Nine pieces of blades 1 are arranged on the runner, and the cross-se...

Embodiment 3

[0051] In this embodiment, the diameter D of the runner is 1483 mm. The section of the runner blade is a hyperbolic airfoil composed of the first airfoil and the second airfoil. At the runner diameter D, the chord length C of the blade airfoil is 0.325D, and the leading edge radius of the airfoil is r 1 is 0.0045D, the airfoil trailing edge radius r t is 0.0045D, and the blade back profile radius R of the first airfoil part where the leading edge of the airfoil is located 11 is 0.25D, and the radius R of the leaf pot shape line 12 is 0.30D, the blade back profile radius R of the second airfoil part where the trailing edge of the airfoil is located t1 is 0.25D, and the radius R of the leaf pot shape line t2 is 0.30D, the placement angle Beta of the first airfoil of the blade 1 is 70°, the placement angle Beta of the second airfoil 2 is 72°. The airfoil chord length C of the second airfoil part 1 is 0.16D.

[0052] Nine pieces of blades 1 are arranged on the runner, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com