Integrated high-salt wastewater MBBR (moving bed biofilm reactor) treatment device

A high-salt wastewater and treatment device technology, applied in the field of environmental protection and wastewater treatment, can solve the problems of poor system operation stability, insufficient salt tolerance, long start-up period, etc., to achieve the effect of ensuring high efficiency and overcoming the long start-up period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

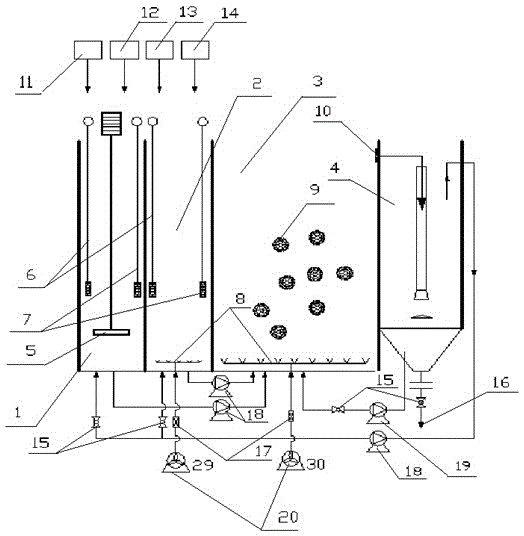

[0029] Embodiment 1, with reference to figure 1 , an integrated high-salt wastewater MBBR treatment device: including an MBBR aeration tank 3 equipped with a suspended filler 9 and a microbial cultivation device connected thereto, wherein the MBBR aeration tank 3 is used to treat high-salt wastewater, microbial cultivation The device is used for the cultivation of salt-suitable microbial flora; and the mixed solution of salt-suitable microbial flora cultivated by the microbial cultivation device enters the MBBR aeration tank 3 for degrading the organic matter in the high-salt wastewater and growing on the surface of the suspended filler 9 hanging film.

Embodiment 2

[0030] Example 2, in the integrated high-salt wastewater MBBR treatment device described in Example 1: the microbial culture device was inoculated with the compound saline microbial agent prepared by Patent Application No. 201310540099.X.

Embodiment 3

[0031]Embodiment 3, in the integrated high-salt wastewater MBBR treatment device described in embodiment 1 or 2: the microbial cultivation device consists of a culture aeration tank 2, a carbon source dosing device 11, a nutrient dosing device 12, and a pH adjustment device 13 , an online dissolved oxygen meter 6 and an online pH meter 7. The microorganism cultivation device may also include an anaerobic hydrolysis tank 1, and the anaerobic hydrolysis tank 1 and the culture aeration tank 2 are co-built together.

[0032] The carbon source dosing device 11 and the nutrient dosing device 12 are arranged on the top of the anaerobic hydrolysis tank 1, and the pH adjustment device 13 is arranged on the top of the culture aeration tank 2, and both the anaerobic hydrolysis tank 1 and the culture aeration tank 2 are arranged There are online dissolved oxygen meter 6 and online pH meter 7 .

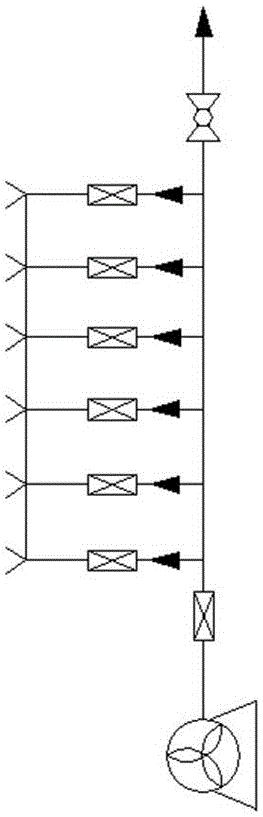

[0033] The aeration device 8 is installed at the bottom of the cultivation aeration tank 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com